Distributed fiber optic sensing (DFOS) technology is reshaping the way construction professionals and engineers apply sustainable infrastructure monitoring in the industry. This technology’s main benefits include smart material usage, better waste reduction strategies, and improved safety measures, ultimately promoting a circular economy in construction.

What is fiber optic sensing technology, and how does it work?

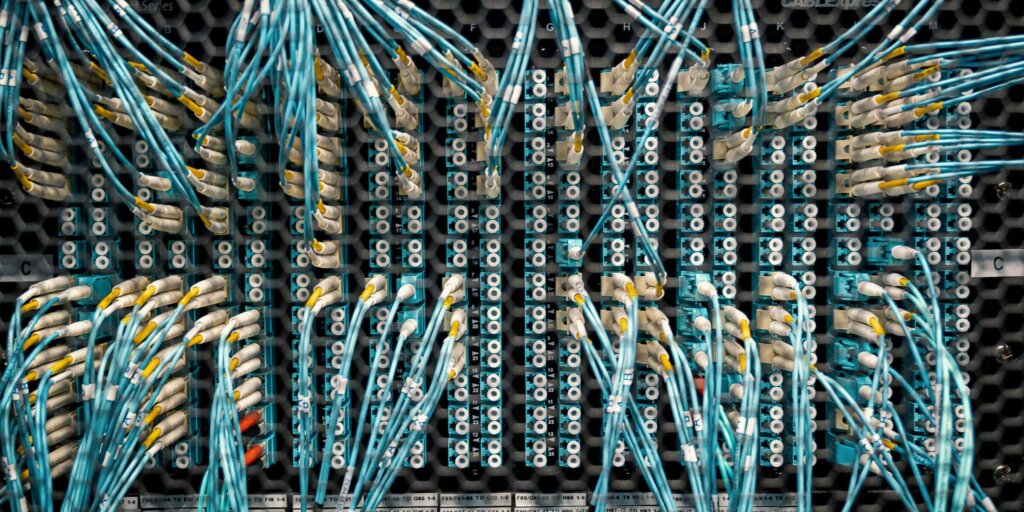

DFOS utilizes optical fiber sensors to measure temperature and strain. These sensors are lightweight and resistant to electromagnetic interference, in contrast to traditional sensors. In construction applications, DFOS offers distributed, continuous measurements over long distances. This technology is employed for infrastructure monitoring, including assessing environmental conditions and reevaluating industrial processes.

This technology is increasingly impactful in promoting the sustainability of construction, engineering, and architecture. It works by sending pulses of light through a fiber optic cable. It then analyzes the backscattered light upon its return. The results are reliable readings of temperature and strain (or vibrations) along the fiber.

How DFOS supports circular construction practices

Smart material usage

DFOS allows engineers to better monitor load distribution and simplify their design methodology. They can also reduce the impact of over-engineering and use fewer material resources wherever possible. This waste reduction plan, which involves only using materials truly needed for each project, promotes a circular construction practice and streamlines processes.

Sustainable building and infrastructure monitoring

It’s becoming increasingly common to embed fiber optic cables in concrete, another construction element making strides in sustainability, to monitor a building’s structural integrity and performance. This allows engineers to detect micro-cracks before they become problematic and thereby extend the structure’s life.

DFOS technology can also be retrofitted to pile foundations, and the pile can be assessed to see how much is suitable for reuse.

Improved safety measures

By assessing design loads against measured loads, discrepancies can be identified at an earlier stage, allowing for adaptation and pivots in the construction process. For example, overloaded load-bearing walls and elements can be minimized when detected early. Then, the project can be redirected to prevent incidents and potential injuries or fatalities from building collapse.

Smarter waste-reduction strategies

When a structure’s strains and stresses are identified, engineers and construction professionals can better assess which materials are required to maintain its structural integrity in future projects. They can also determine which materials, if any, can be extracted and reused to promote the building’s longevity.

This is just one smart sustainability strategy, facilitating a shift from linear construction to a more circular model, where resource conversation, material optimization, and waste reduction are key to current and future building.

Recommended fiber optic sensing technology applications in construction

Structural health monitoring for bridges and tunnels

DFOS technology is increasingly used to measure the structural integrity and health of bridges and tunnels. The monitoring comprehensively assesses any potential stress points or potential damage across large areas with high-resolution and sensitive data.

Geotechnical monitoring for soil stability

DFOS sensing parameters can also determine soil moisture content and displacement, potentially detecting landslide risks early. Given the risk level of a specific area, this technology aids construction project managers in site selection and project scope.

Pipeline and utility infrastructure monitoring

Lastly, DFOS technology is frequently utilized in pipeline and utility monitoring due to its leak-detection capabilities. The fiber optic cables can identify leaks and vulnerable areas in pipes, tunnels, tubing, and other utility materials and infrastructure. This accurate and timely damage detection enables workers to be proactive about repairs and material usage.

Final thoughts

The construction industry collectively introduces more sustainable practices in every phase, from concept to completion. DFOS comes into play during the design process for structural health monitoring by allowing continuous assessment of vulnerabilities and by giving engineers and construction professionals better building strategies for future projects.

This circular impact disrupts the linear construction model and paves the way for smarter material usage, increased waste reduction, and improved safety measures.

For the latest on technology in the AEC space, subscribe to the newsletter and follow us on LinkedIn.