Artificial intelligence (AI) has revolutionized many industries but none more so than manufacturing. This is where AI was first used on a wide scale across many industrial applications. Up until now, humans were always overseeing the production lines in factories to ensure quality control, such as on a car assembly line. But now, the function and capabilities of industrial AI have expanded far beyond just performing one task. The emergence of fully automated “Smart Factories” in countries like China and Japan have reduced the need for workers altogether. This development has raised concerns about the future of work while at the same time showing the incredible potential for driving productivity.

AI applications in factory automation

Artificial intelligence is already highly integrated into industrial automation with various collaborative robots performing repetitive assembly tasks. The use of autonomous systems on the factory floor has shown to improve operational efficiency, reduces costs, and maintains a consistent product quality. However, recently manufacturers have begun to explore outsourcing other key components of industrial processes to AI, including high-level decision making that was performed by humans.

Supply chain management

By analyzing vast amounts of data, AI can predict potential disruptions and resource shortages in real time. This capability allows AI to make decisions faster and inform humans how to overcome the potential disruptions. It can also forecast demand to predict order volume and automate procurement processes leading to timely deliveries and increased customer satisfaction.

Predictive maintenance

Implementing AI in predictive maintenance allows manufacturers to anticipate equipment failures before they occur. By continuously monitoring machinery through sensors and analyzing performance data, AI models can identify patterns indicative of potential issues. This proactive approach reduces unplanned downtime, extends equipment lifespan, and lowers maintenance costs. Companies like General Motors have successfully utilized AI-driven predictive analytics to forecast maintenance needs, resulting in significant operational cost savings.

Automating assembly processes

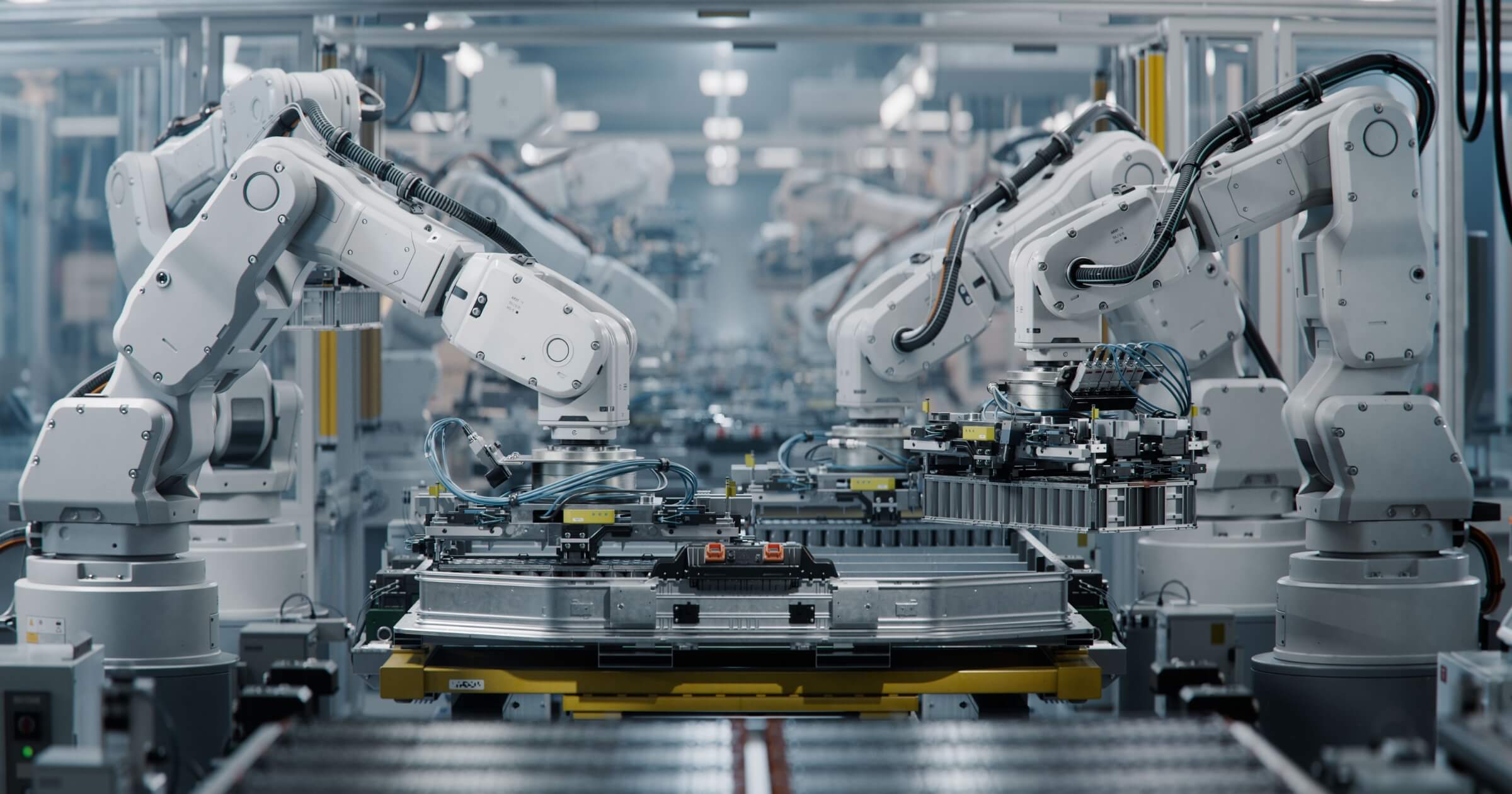

AI-powered robots are transforming manufacturing floors by working alongside human operators. These robots can adapt to various tasks with minimal programming. For instance, cobots assist in assembly lines by lifting heavy parts and handling precise tasks where human hands may fall short.

Digital twin technology

Digital twins are virtual replicas of physical assets, systems, or processes that allow manufacturers to simulate and analyze real-time behavior. By integrating AI with digital twins, companies can monitor performance, predict outcomes, and optimize operations without physical intervention. This technology enhances decision-making and reduces downtime. For example, Siemens has integrated an AI-based program for predictive quality management, allowing the company to maintain a high product quality and minimize waste.

Collaborative robots

Collaborative robots, or cobots, have seen a massive rise in use in the past decade. Companies like Amazon have used robots to expedite the process of shipping in their large warehouses. Equipped with computer vision and sensors, cobots can perform complex tasks such as assembly, welding, and packaging. Their ability to make data-driven decisions and adapt to new tasks makes them valuable assets in real-world settings.

Generative design

Generative design leverages machine learning algorithms to explore a multitude of design possibilities based on specified constraints and parameters. Engineers input design goals, materials, manufacturing methods, and other requirements into the gen AI system, which then generates optimized design alternatives. This approach leads to innovative solutions that may not be immediately apparent through traditional methods, resulting in products that are both efficient and cost-effective.

Energy optimization

Manufacturing plants often face major challenges related to energy waste due to inefficient processes and poor load balancing. AI analyzes energy consumption patterns to identify areas where power is wasted and suggests adjustments to optimize energy use. Implementing AI-driven energy management systems have shown to reduce operational costs contributing to more sustainable manufacturing practices.

Benefits and challenges of using industrial automation systems

Benefits

Cost reduction

There are various ways that AI can help reduce costs for manufacturers. The main ones include:

- Reducing waste

- Predicting maintenance needs

- Automating routine tasks

- Streamlining supply chain management

- Lowering storage costs

- Efficient use of resources

- Working 24/7

Increased productivity

Machines can operate around the clock without breaks, allowing manufacturers to maximize production output while minimizing labor costs. Gen AI can now handle complex tasks, such as supply chain optimization at speeds and accuracies far beyond human capabilities. This capability of making real-time decisions with a high-accuracy gives it a competitive edge over humans.

Improved safety

AI improves workplace safety by minimizing human involvement in hazardous tasks. AI-powered robots can inspect the site for work hazards, keeping human workers out of dangerous environments. With AI now being integrated with smart devices it can also monitor workers’ health by using sensor data to detect unsafe working conditions.

Optimized design

Software solutions powered by gen AI allow engineers to create innovative and optimized product designs. AI software can explore countless design possibilities based on parameters such as material properties, manufacturing processes, and cost constraints. The result is a design that not only meets performance standards but also minimizes material usage and production costs. This helps manufacturers achieve more sustainable and cost-effective designs, ultimately driving both environmental and economic benefits.

Challenges

High implementation costs

While AI promises significant benefits, the upfront costs associated with implementing AI technologies can be prohibitive. Integrating AI applications into existing manufacturing control systems often requires substantial investment in new hardware, software, and specialized infrastructure. Additionally, there are costs associated with training employees to work with AI systems.

Data security

The increased reliance on data-driven AI systems raises significant concerns about data security. AI in manufacturing relies on vast amounts of real-time data, which can be vulnerable to cyber-attacks or breaches. If sensitive company data or intellectual property is compromised, it can lead to financial losses and damage to a company’s reputation.

Skill shortages

As the digital transformation continues to reshape the manufacturing industry, there is a growing demand for skilled workers who can operate, maintain, and optimize AI systems. However, many manufacturing companies face difficulties finding employees with the necessary technical expertise in AI, machine learning, and robotics. This skills gap can hinder the adoption of AI technologies, especially in smaller companies with limited resources for training and development.

Data quality

The effectiveness of AI use relies heavily on the quality of the data it processes. Inaccurate or incomplete data can lead to faulty predictions, inefficiencies, and even equipment failures.

High energy use

Although AI can optimize manufacturing processes, its own energy consumption can be significant. AI systems require substantial computing power to analyze large datasets, which can result in higher energy costs and a larger environmental footprint.

The future of industrial automation may lead us to the fourth industrial revolution

With the rise of generalized robots like Tesla’s Optimus and Figure’s 02, the future of manufacturing will likely lead to fully automated factories, also known as “dark factories.” This may seem like sci-fi but dark factories are already a reality in countries like Japan and China. The Japanese company Fanuc operates a fully autonomous factory to build its own robots, often working up to 30 days without any human intervention.

As AI use in industrial automation continues to get more sophisticated, dark factories will likely become more common. The countries that don’t adopt this approach are likely going to be left behind as costs of production from a fully autonomous factory will be much lower than a human run one.

While the cost benefits are evident, the shift toward using Ai in industrial automation to complete the entire process has significant implications for workers. As machines take over more roles, there will be a decline in the demand for certain types of manual labor. However, this will create new job opportunities in areas such as AI system management, robotics maintenance, and data analysis. For workers in the AEC industries, adapting to these changes may require reskilling and ongoing education to stay competitive in an AI-driven job market.

On the environmental front, AI-driven automation offers the potential to reduce waste and improve sustainability. Through more precise production methods, manufacturers can minimize material usage and energy consumption, contributing to a lower carbon footprint. However, the increased energy demands of AI systems themselves may pose serious challenges. Balancing the energy consumption of AI with the need for sustainable practices will be a critical issue for the future.

Bottom line

Smart manufacturing will revolutionize industrial settings in ways we’ve never seen before. However, the implementation of AI systems in industrial processes comes with challenges that must be addressed, such as energy usage, data security concerns, and skill shortages. As the industry moves forward, expect to see gen AI involved in more use cases such as running smart factories to being in charge of business operations.

Want to learn more about the future of manufacturing and industrial automation? Subscribe to our newsletter at Under the Hard Hat to stay updated on the latest trends and insights!