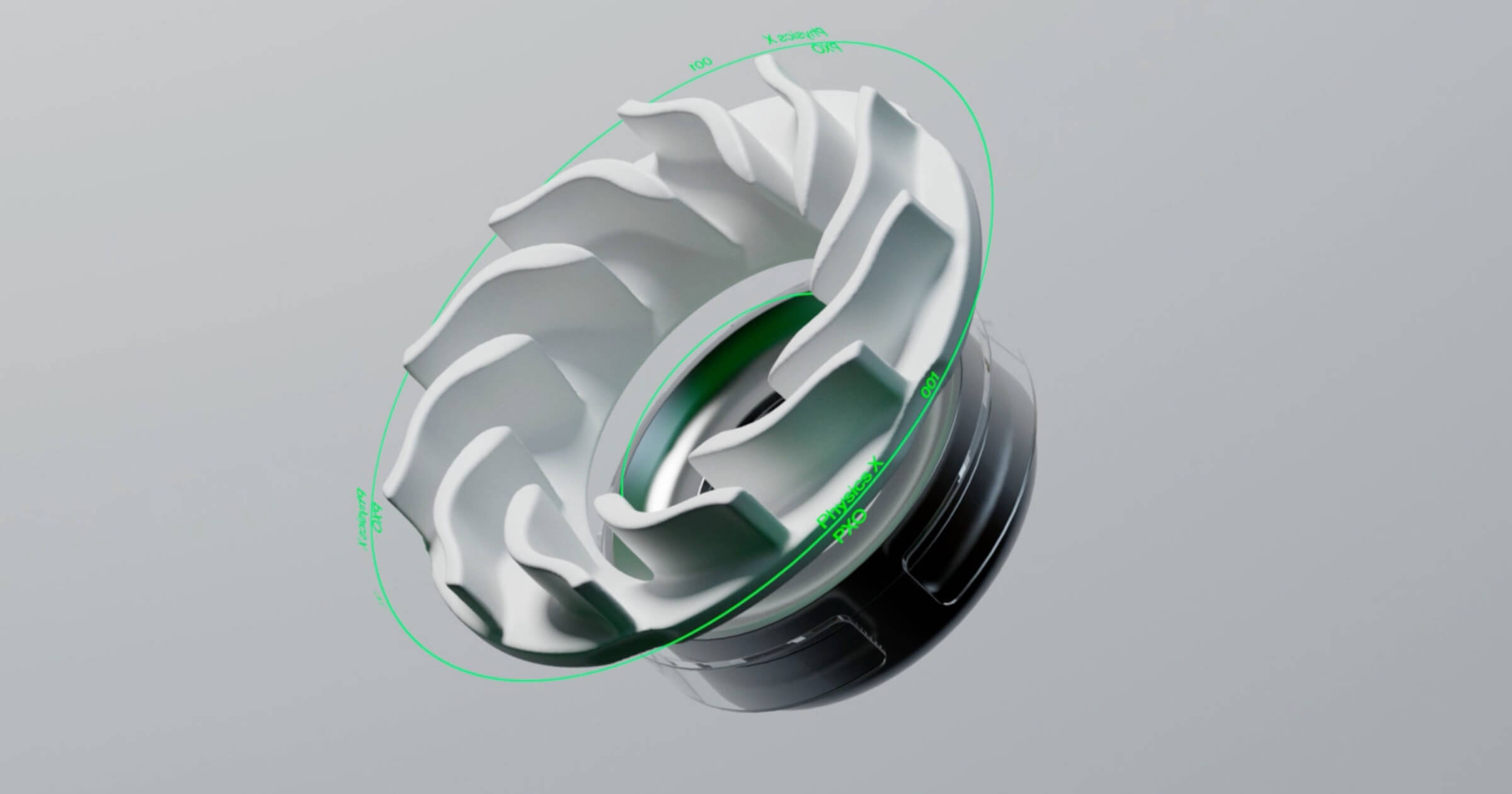

PhysicsX is making waves in industrial engineering, and it’s not with hardware. This UK-based company utilizes advanced AI technology to enhance the design and optimization of physical systems. From automotive suspension to heat exchangers and even medical implants, they’re cutting months off development cycles and delivering higher-performing solutions.

An AI company built by engineers

PhysicsX was founded by engineers who recognized that AI wasn’t being applied to the real-world problems industrial designers were facing. This included complex physical simulations that typically required hours or even days of computing time.

Traditional methods, such as finite element analysis (FEA) or computational fluid dynamics (CFD), aren’t going anywhere, but PhysicsX is speeding them up dramatically by training neural networks to mimic these processes. These surrogate models don’t replace simulation entirely, but they reduce the number of full simulations teams need to run.

Think of optimizing the geometry of a steel connection, wind modeling on a high-rise façade, or stress tests for prefabricated concrete panels. In each case, faster feedback loops mean better performance before breaking ground. And when every revision costs time and money, shaving days off the design validation process has significant value.

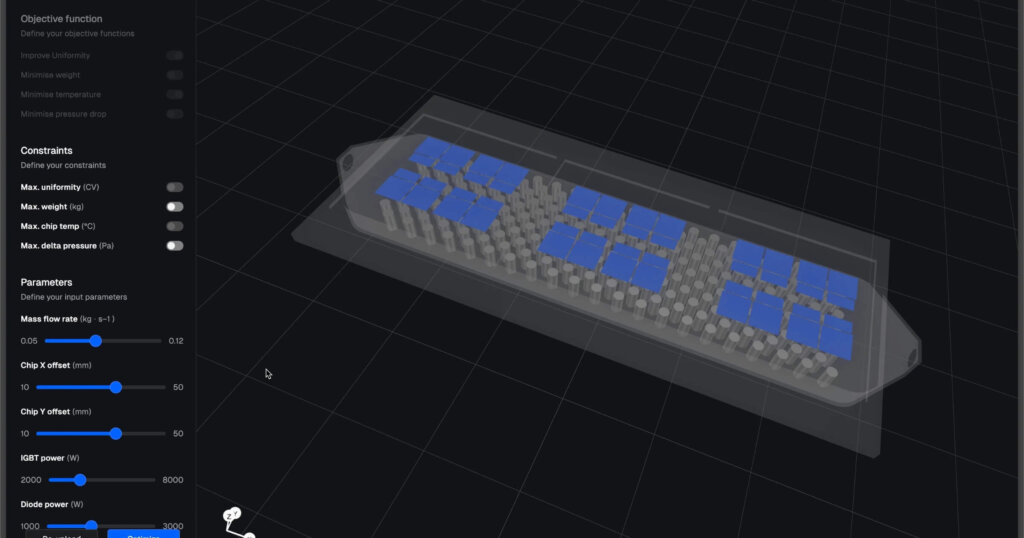

PhysicsX software and simulator: How it works

Image courtesy of https://www.physicsx.ai/

PhysicsX trains custom AI models for each client based on their own physical systems. So rather than selling a generic platform, they embed into a company’s workflow and tune the model to what that team is building.

One example of their work included a client needing to optimize the cooling channels in a die-casting mold. Usually, this would take dozens of FEA runs and weeks of iteration. With PhysicsX’s AI-driven modeling, they were able to simulate thousands of variations in hours, not days. That accelerated design process saved cost, but it also improved the quality and lifespan of the finished product.

While much of their current work centers on manufacturing and the automotive industry, the same technology has direct applications in the built environment. HVAC systems, structural connections, vibration control, and thermal bridges all benefit from rapid simulation. Engineering firms seeking to gain an edge in speed and accuracy should closely monitor this company.

If a tool can reduce simulation time, improve material use, or flag problems earlier in design, it can help deliver better buildings faster. PhysicsX is one of the few AI-powered companies doing just that, and their approach could influence how future projects are planned and delivered.

Want to stay in the loop on how tech is reshaping engineering? Subscribe to our newsletter at underthehardhat.org/join-us for more company spotlights and tools that matter on the jobsite.