Construction companies juggle rising costs, tight labor markets, and fleets working across multiple job sites. Clue is an operations platform designed to help contractors see and manage their equipment and resources in one place. It was built to solve the day-to-day problems that many contractors face. On big jobs with lots of machines and crews, equipment can sit idle, miss maintenance schedules, or lose tracking between systems altogether. Clue unifies that information using data and smart tools so teams have one clear picture of what is happening, as it happens.

What Clue brings to contractor operations

Instead of managing equipment through separate tools, Clue connects everything you need into one system, allowing teams to get a clearer picture of what is happening across job sites.

At a practical level, Clue brings together:

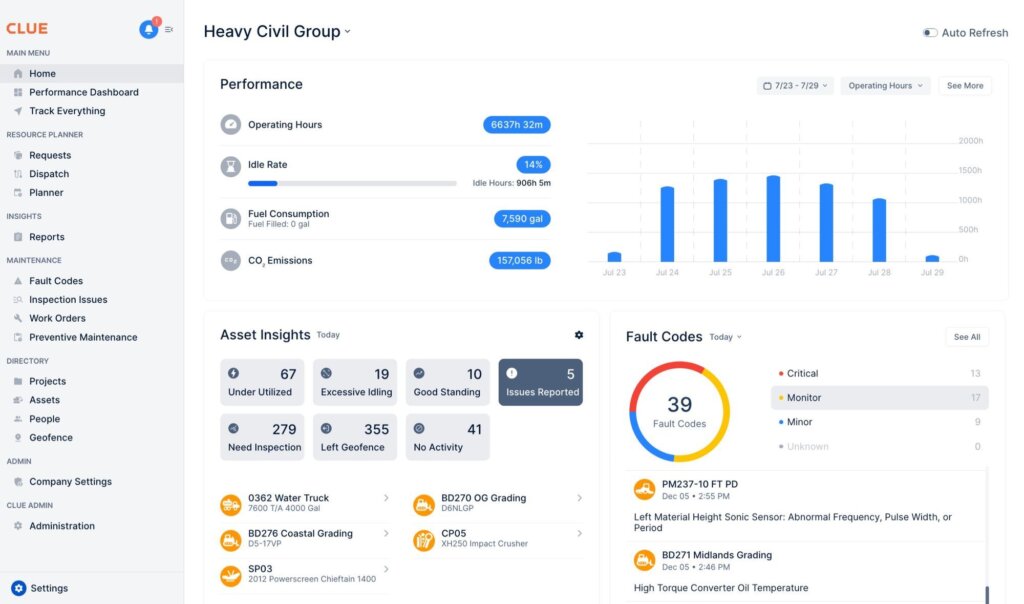

- Telematics and GPS data to track equipment location, hours of operation, fuel use, and fault codes

- Maintenance and inspections, including digital checklists, photos, work orders, and preventive maintenance schedules

- Jobsite activity through automated jobsite detection and geofence alerts

- Equipment utilization and productivity to show how assets are being used and where time or fuel is being wasted

- Enterprise systems like ERP and reporting tools, so operations, equipment, and management teams work from the same data

Clue home dashboard showing tracking of assets, repair and maintenance status, and performance insights.

Whether equipment is owned or rented, Clue shows where it is, how it is performing, and what needs attention. That means less time swapping between apps and more time fixing issues fast. With this unified approach, Clue reduces manual work, prevents missed maintenance, and improves equipment availability across multiple projects.

Benefits of using Clue for construction operations

| Without Clue | With Clue |

| Equipment data spread across telematics, GPS, maintenance tools, and spreadsheets | One platform that integrates telematics, GPS, maintenance, and ERP systems |

| Limited visibility into where equipment is and how it is being used | Instant location tracking, operating hours, and utilization data |

| Manual inspections and disconnected maintenance records | Digital inspections with photos, work orders, and preventive maintenance tracking |

| Missed fault codes or delayed response to equipment issues | Centralized fault codes and faster response to breakdowns |

| Equipment sitting idle or rented unnecessarily | Utilization insights that highlight underused or excess equipment |

| Manual jobsite setup and tracking | Automated jobsite detection and geofence alerts |

| Productivity tracked manually or after the fact | Real-time productivity tracking for earthwork projects |

How contractors use Clue to simplify and streamline operations

The clarity and ease of using Clue makes a big difference. “We had 20 different logins between all our different software… now Clue pulls all that information into one spot!” says Derek Wolfe, Equipment Manager at George Igel Co.

Clue’s tracking includes location, engine hours, fault codes, and fuel levels across machines. These details instantly help teams spot underused equipment, reduce idling, and cut back on unnecessary rentals. Over time, this can add up to big savings.

Maintenance gets easier with Clue, too. Digital inspections let crews add photos and notes right from the field. Preventive maintenance schedules and work orders keep tasks organized with parts and labor details all in one place. “Before we started using Clue, there was a lot of running around… constantly having the foreman or technicians email us or call us with that information to manually enter that,” says Amber Smith, Equipment Maintenance Scheduler at Silver Star Construction. With Clue, everyone stays up to date without paper forms or long email chains.

To get a detailed look into how equipment management is streamlined with Clue check out their explainer video below.

The platform also includes AI-driven features to help teams work smarter, not harder. Tools like automated job site detection, geofence alerts, and utilization tracking show how equipment is managed daily. On heavy civil and earthwork projects, especially, Clue helps teams see productivity trends without extra manual reporting.

Project managers, superintendents, operations leaders, mechanics, and countless other teams can each use dashboards tailored to their needs. It runs on web and mobile, and even works offline, so crews in remote areas can keep logging data without interruption. “Within 20 minutes you can fully explain to any individual, regardless of their tech background, how to use the tool,” says Joseph Yammine, Project Manager at Graham.

Some customers have seen major savings. “We saved over $1 million in our first year alone using Clue… and we transitioned our mechanics from 2 services a day to 6 services a day thanks to Clue,” says Darrin Sheriff, Director of Maintenance & Purchasing at Palmetto Corp. And Silver Star Construction’s equipment manager adds, “Our equipment is in far better shape since we started using Clue. It would be difficult for us to go back.”

For more stories like this delivered straight to your inbox, subscribe to our newsletter for weekly updates on construction technology and innovation.