Electrical hazards are a significant concern in construction, where the risk of accidents is high due to exposed wires, live circuits, and heavy machinery. Understanding these hazards and how to prevent them is crucial for ensuring the safety of everyone on-site. From electric shocks to fires, the dangers are real, but with proper training and implementation of appropriate safety measures, they can be effectively managed.

Quick look

- The construction industry faces one of the highest dangers from electrical hazards, with inadequate training and a lack of hazard recognition contributing to this.

- Electric shock and burns from contact with live wires, exposure to arcing, and fires from faulty equipment or installation are some of the most common causes of electrical injuries.

- Human beings are more conductive than the ground, meaning live electricity can cause serious damage if a person becomes part of a live electrical circuit.

- Electrical risk assessments, proper training, and the implementation of safety measures are the easiest ways to reduce the risk of electrical hazards.

Dangers of electricity

Electricity, while essential on construction sites, poses significant risks when not properly managed. The construction industry faces one of the greatest dangers from electrical hazards, with most accidents occurring due to inadequate training and a lack of hazard recognition. These hazards include the potential for electric shock, burns, and even fatal accidents, often resulting from direct contact with live wires or faulty equipment.

Awareness is critical to protect against these dangers. Understanding the risks associated with electricity enables workers to take necessary precautions, spot hazards early, and ensure a safer working environment.

5 main electrical hazards

Electrical hazards on construction sites are numerous and can lead to severe injuries or fatalities if not correctly managed. Here are the five main electrical hazards to be aware of:

- Electric shock and burns from contact with live parts: One of the most common electrical hazards, electric shock occurs when a person comes into direct contact with live electrical components. Depending on the voltage and duration of exposure, it can result in severe burns, muscle contractions, or even cardiac arrest.

- Injury from exposure to arcing: Arcing happens when electricity jumps from one circuit to another, creating intense heat and light. This phenomenon can cause burns, ignite fires, and lead to explosions, especially in environments with flammable materials.

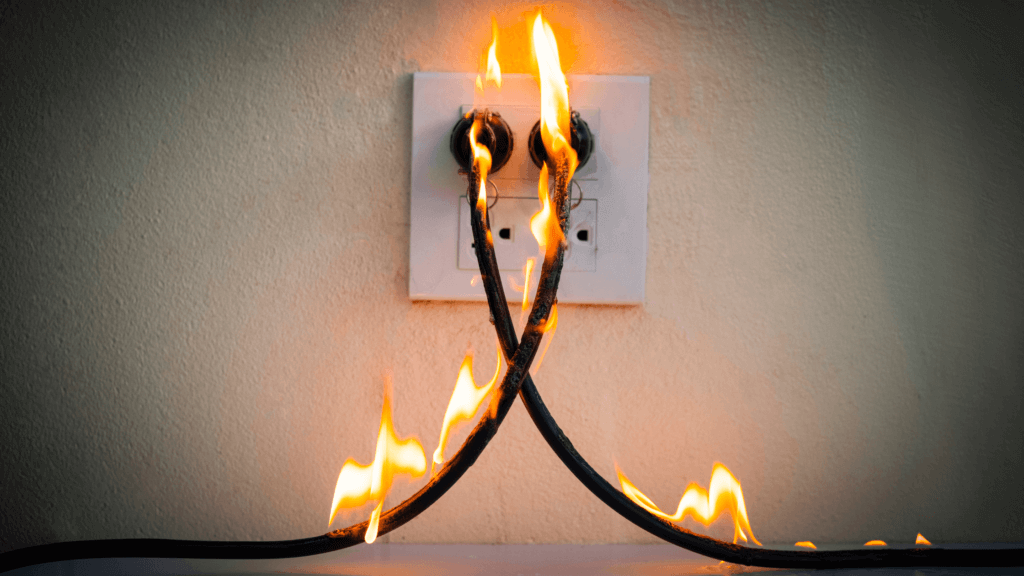

- Fire from faulty electrical equipment or installations: Faulty wiring, overloaded circuits, or malfunctioning electrical devices can easily start a fire. Electrical fires can spread quickly, causing extensive damage and risking lives.

- Explosion caused by unsuitable electrical apparatus: In specific environments, especially those with flammable vapors or dust, unsuitable or poorly maintained electrical equipment can cause explosions. These explosions can have devastating consequences, both in terms of human life and property damage.

- Static electricity igniting flammable vapors or dust: Static electricity can build up and discharge in environments where flammable vapors or dust are present, such as in spray paint booths or grain silos. This discharge can ignite the combustible materials, leading to explosions or fires.

Injuries from electrical currents

When a person becomes part of an electrical circuit, the body can suffer severe injuries because it is more conductive than the ground. Four primary types of injuries resulting from electrical currents are electrocution (fatal), electric shock, burns, and falls.

These injuries can occur in several ways:

- Direct contact with live conductors can disrupt vital signals in the body, potentially stopping the heart or breathing.

- When electricity “arcs” jump to a person who is grounded, it can cause severe burns and shocks.

- Thermal burns can result from the heat generated by an electric arc, damaging both internal and external tissues.

- Arc blasts can release pressure waves that cause physical injuries or hearing loss.

- Muscle contractions or shock responses can lead to falls from ladders or scaffolding.

How to prevent electrical hazards

Preventing electrical hazards on construction sites is crucial for the safety of workers and to avoid accidents. A comprehensive approach includes proper electrical risk assessments, thorough training, and the implementation of effective safety measures. Here’s how to tackle each aspect:

Electrical risk assessments

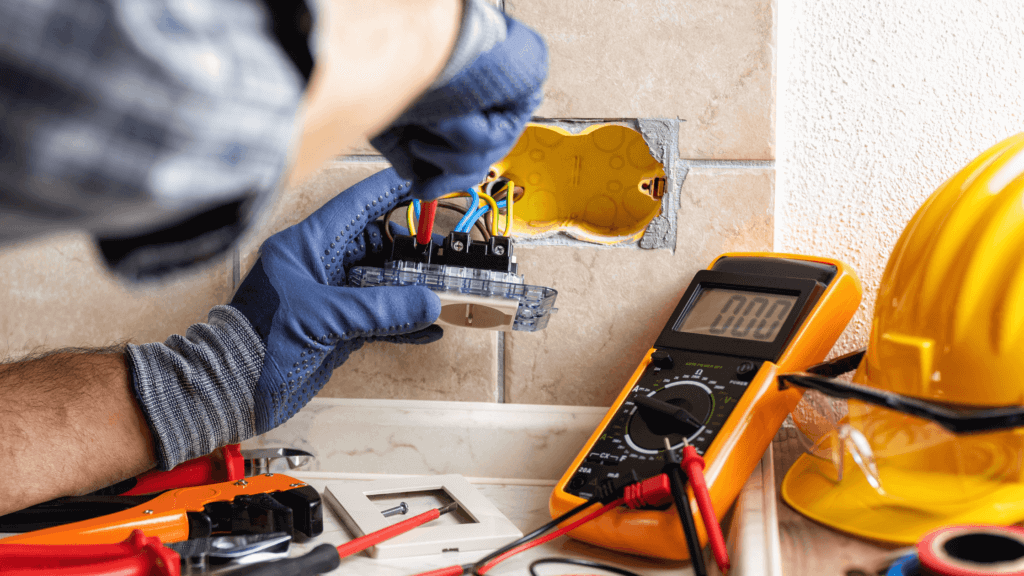

Conducting regular electrical risk assessments is the first step in identifying and mitigating potential electrical hazards. This process involves inspecting all electrical systems, equipment, and installations on-site. Look for damaged or exposed wiring, overloaded circuits, improper grounding, and malfunctioning equipment. It’s essential to assess the severity and likelihood of each identified hazard, prioritize them, and implement control measures such as repairing faulty equipment, improving insulation, and ensuring proper grounding. Regularly reviewing these assessments helps keep the worksite safe as conditions change.

Training

Training is vital in reducing the risks associated with electrical hazards. Workers must receive training on recognizing electrical hazards, using personal protective equipment (PPE), and following safety protocols. This training should cover the basics of electrical safety, including properly handling electrical tools, the importance of not working in wet conditions, and how to respond to an electrical emergency. It’s also essential to provide site-specific training that addresses the unique electrical risks of the particular job site.

Implementation of safety measures

To further prevent electrical hazards, several safety measures should be implemented:

- Lockout/Tagout (LOTO): Ensure equipment is properly de-energized before maintenance or repair work. A multi-lock system can prevent accidental energization when multiple workers are involved.

- Use of ground fault circuit interrupters (GFCIs): GFCIs can prevent electrocution by cutting off the electrical supply if a ground fault occurs. These should be used, especially in wet or damp environments.

- Proper use of PPE: Workers should always wear appropriate PPE, such as insulated gloves, safety glasses, and non-conductive boots when working near electrical hazards. This equipment helps protect against shocks, burns, and other injuries.

- Use of non-conductive tools: When working on or near electrical systems, using tools made of non-conductive materials like fiberglass or plastic can prevent accidental electrical contact.

- Emergency response planning: Having a well-defined emergency response plan is critical. This plan should include procedures for dealing with electric shocks, electrical fires, and other emergencies. Workers should be trained on these procedures and have access to first aid equipment.

Key takeaways

Keeping construction sites safe from electrical hazards is all about good planning, proper training, and sticking to safety rules. Regular checks of equipment, using the right protective gear, and ensuring everyone knows the risks can go a long way in preventing accidents. Staying vigilant and being prepared for emergencies can significantly lower the chances of electrical incidents on the job.

4 comments