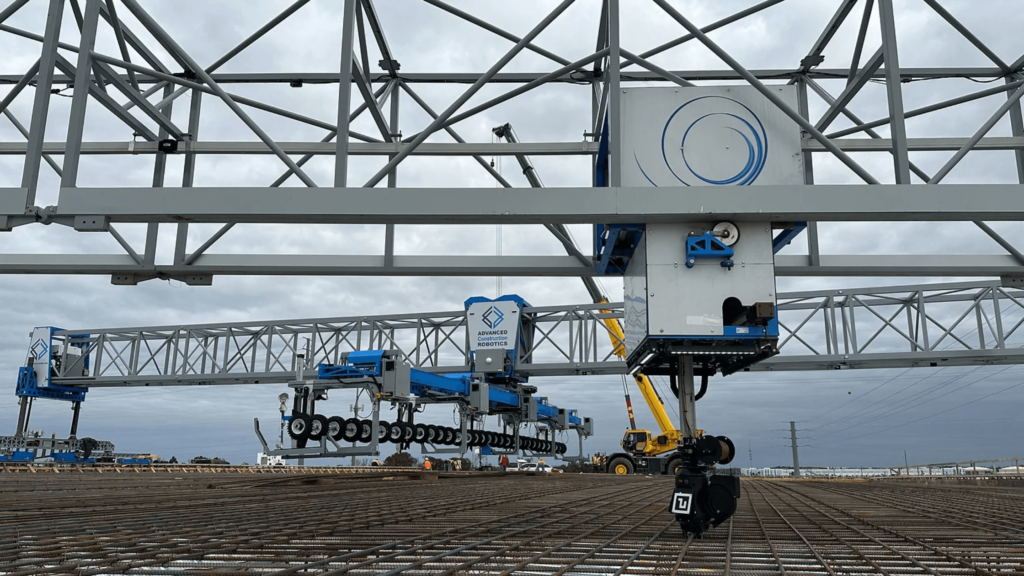

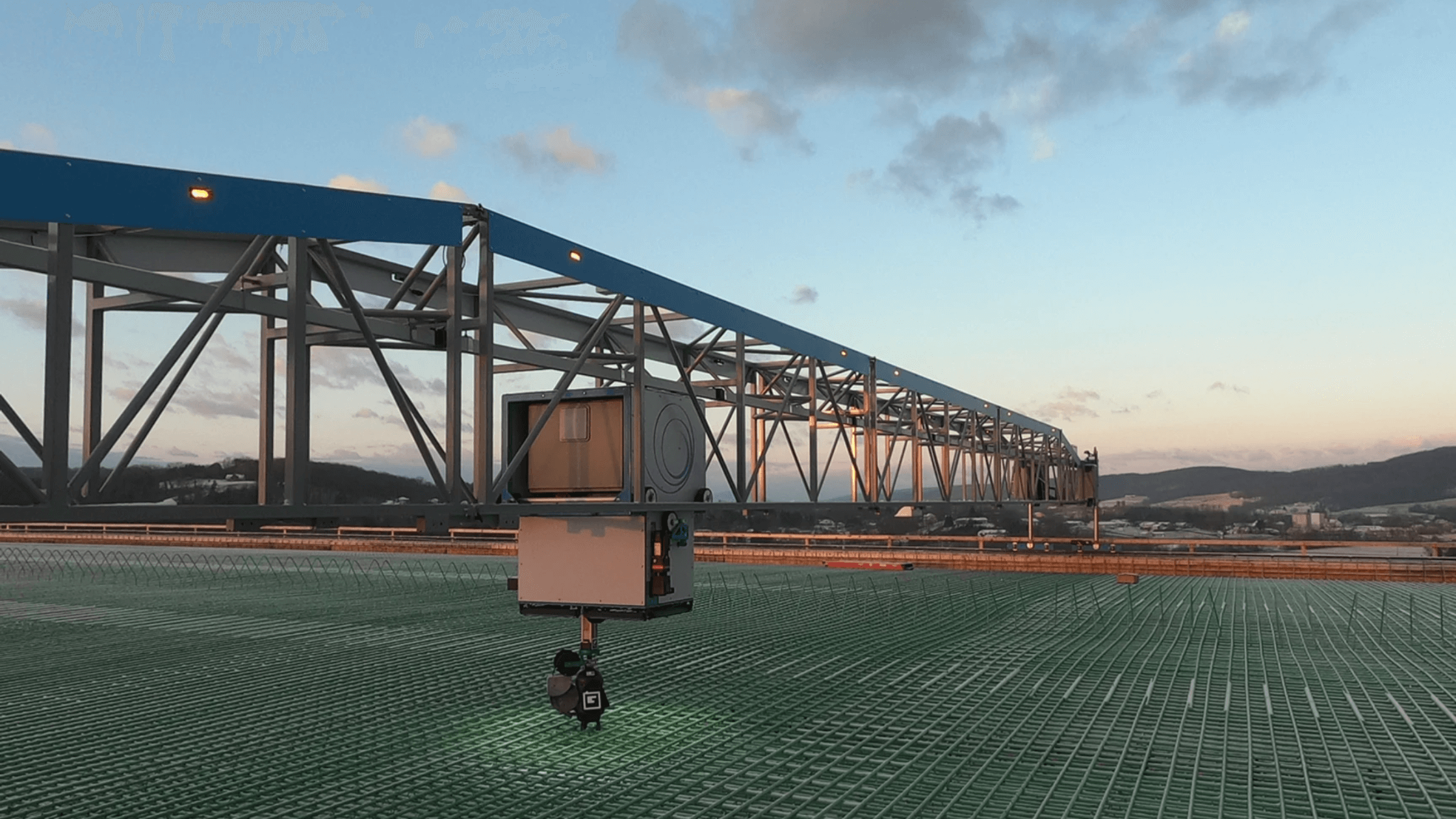

The construction industry just got a tech upgrade with the launch of the third-generation TyBot 3.0. Developed by Advanced Construction Robotics (ACR), this latest version of the rebar-tying robot promises to revolutionize concrete construction, making it safer, faster, and more cost-effective.

TyBot 3.0 is an autonomous robot that ties rebar on bridge decks, concrete pavements, and other reinforced concrete structures. Its sophisticated technology allows it to work without human intervention, using advanced sensors and artificial intelligence to identify rebar intersections and secure them efficiently. TyBOT requires no pre-mapping, programming, or calibration and can automatically locate, position, and tie over 1,200 rebar intersections every hour. This new generation offers improved speed, precision, and flexibility, adapting to different rebar sizes and complex configurations.

This next-gen bot addresses several challenges in the construction industry, including labor shortages and worker safety concerns. By automating the labor-intensive and physically demanding task of tying rebar, TyBot 3.0 significantly reduces the risk of injury to workers, especially those exposed to repetitive strain and harsh environmental conditions. Additionally, it enhances project timelines, allowing for faster rebar tying without compromising quality.

The robot’s efficiency also translates to cost savings, as it can work longer hours without breaks, reducing labor costs and accelerating project completion. For an industry constantly battling tight schedules and budgets, TyBot 3.0 offers a much-needed productivity boost. Taking on tedious tasks frees up skilled workers to focus on more complex, high-value aspects of construction projects.

As the demand for smart construction solutions grows, TyBot 3.0 sets a new standard for innovation, positioning ACR as a key player in the move toward a more automated, safer, and sustainable construction future.

1 comment