Millions rely on bridges daily to get to work, transport goods, and connect communities. Yet, a staggering number of these critical structures are aging and in dire need of repair, with over 42% of U.S. bridges over 50 years old and 8% rated in poor condition. As the nation’s infrastructure continues to wear down, swift action becomes more urgent to ensure safety, efficiency, and economic stability.

Quick look

- Many bridges are over 50 years old, with 8% rated in poor condition, posing significant safety and economic risks.

- Iowa, Pennsylvania, Illinois, and California lead in structurally deficient bridges. These states face unique challenges, from extreme weather to seismic risks.

- Federal funding, advanced materials, real-time monitoring systems, and public-private partnerships are driving progress in bridge repairs.

- Delayed maintenance raises costs and safety concerns, making immediate investment in infrastructure a national priority.

The state of U.S. bridges

The U.S. has over 617,000 bridges, and they’re more than just structures—they keep our country connected and moving. But there’s a growing concern. According to the Federal Highway Administration (FHWA) and the American Road & Transportation Builders Association (ARTBA), more than 42% of these bridges are over 50 years old, and about 8% are in such bad shape that they’re classified as structurally deficient. In other words, they need serious repairs or even complete replacement to stay safe.

Bridges are graded into three categories based on their overall condition:

- Good: These bridges are in great shape, with barely any wear or tear.

- Fair: These are still functional but showing signs of aging, like cracks or rust, that could lead to more significant problems if ignored.

- Poor: Bridges in this category have critical issues that make them unsafe. They often need weight limits or closure until they can be fixed or replaced.

Structurally deficient bridges are a big deal, especially on busy roads. According to ARTBA, there are over 78,800 bridges in this category, and they’re more than just safety hazards. They cause traffic jams, delay freight deliveries, and drive up transportation costs, hurting the economy. With so many bridges stuck in poor or fair condition, fixing and replacing them isn’t just important—it’s something we need to tackle now.

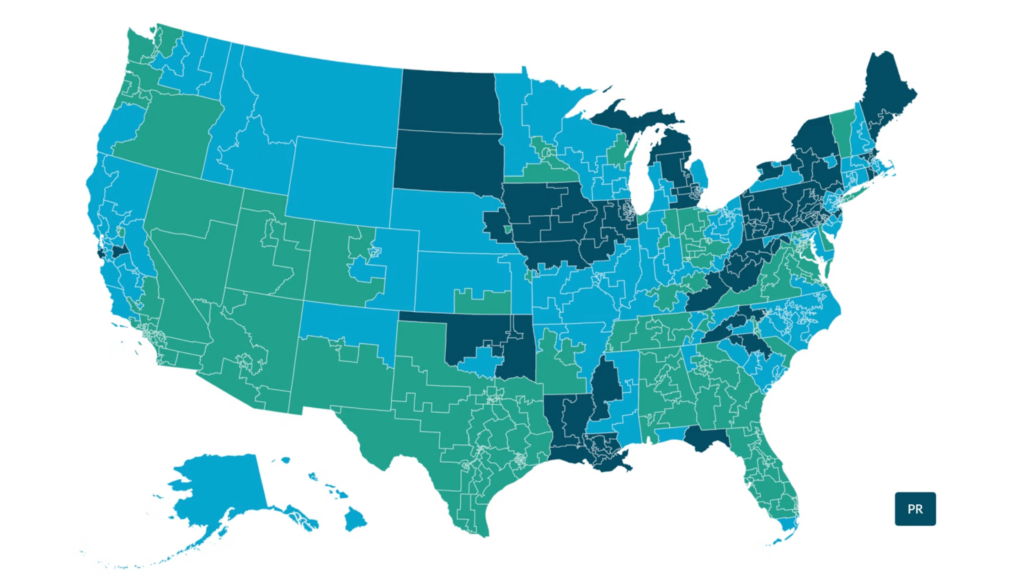

States with the most structurally deficient bridges

Some states are feeling the weight of America’s bridge crisis more than others, with thousands of bridges falling into the “structurally deficient” category. Leading the pack is Iowa, with over 4,500 deficient bridges—more than any other state. Pennsylvania isn’t far behind, with 3,100 bridges in poor shape, reflecting its aging infrastructure and heavy traffic. Illinois and California round out the list, with 2,300 and 2,000 bridges needing urgent repairs.

Each state has its own unique set of challenges. In the Midwest, places like Iowa and Illinois battle harsh freeze-thaw cycles that take a toll on concrete and steel. Pennsylvania’s historic bridges face the dual pressures of old age and dense urban traffic. Meanwhile, California has its own set of problems, dealing with seismic risks that require specialized retrofitting to keep its bridges earthquake-safe.

There’s also a divide between urban and rural bridges. High-traffic cities like Los Angeles and Philadelphia see constant wear and tear from heavy vehicle use, speeding up deterioration. While less busy, rural areas often struggle with older bridges and fewer resources for regular maintenance, leaving many in disrepair for years.

These challenges make one thing clear: every state needs tailored solutions to its specific bridge problems; whether addressing traffic overloads in cities or catching up on maintenance in rural areas, finding the right approach is key to keeping bridges safe and functional.

The economic and safety impact of deficient bridges

When bridges fall apart, the impact goes beyond the structures themselves—it affects safety, transportation, and the economy. Structurally deficient bridges are serious safety hazards. Cracked supports, corroded steel, and shaky foundations make accidents more likely, putting drivers and pedestrians at risk of devastating consequences.

On the economic side, these bridges create all sorts of headaches. Weight limits or closures often mean detours, which delay freight deliveries and drive up transportation costs. Industries that depend on tight schedules, like just-in-time logistics, feel the pinch the hardest—minor delays can throw off supply chains and lead to higher costs for everyone.

And then there’s the price tag for repairs. Waiting only makes things worse. Fixing minor issues early on can stop them from turning into major problems. But when repairs get pushed aside due to tight budgets, costs can skyrocket, often requiring extensive work or complete replacements. Tackling maintenance upfront is far cheaper than dealing with a full-blown emergency later.

The stakes couldn’t be higher. Every day that repairs are delayed puts more people at risk and adds to financial strain. It’s time to make repairing America’s aging bridges a priority.

Federal and state initiatives

The urgency around America’s aging bridges has spurred significant action at both the federal and state levels. One of the standout initiatives is the Infrastructure Investment and Jobs Act (IIJA), which directs a massive $110 billion toward roads, bridges, and other infrastructure upgrades. A significant chunk of this funding flows through the Bridge Formula Program, designed to repair or replace the 15,000 most structurally deficient bridges nationwide, focusing on helping underserved rural and urban areas.

At the state level, creative solutions are taking shape to tackle unique challenges. California, for example, has invested heavily in seismic retrofitting to prepare its bridges for earthquakes. Projects like the updated San Francisco-Oakland Bay Bridge showcase how the state sets new disaster resilience standards.

Pennsylvania is another success story. It uses public-private partnerships (PPPs) to speed up its bridge repairs. Through its Rapid Bridge Replacement Project, the state has replaced over 500 bridges by bundling them into larger repair packages, significantly cutting costs and timelines.

Collaboration between federal, state, and private stakeholders will be critical to effectively and sustainably rebuild America’s bridges.

Technology and innovation in bridge repairs

New technology and engineering breakthroughs are changing the game for bridge repairs and maintenance, making the process faster, more efficient, and more sustainable. With the help of innovative tools and materials, states and cities can tackle bridge issues more effectively and keep these critical structures in good shape for longer.

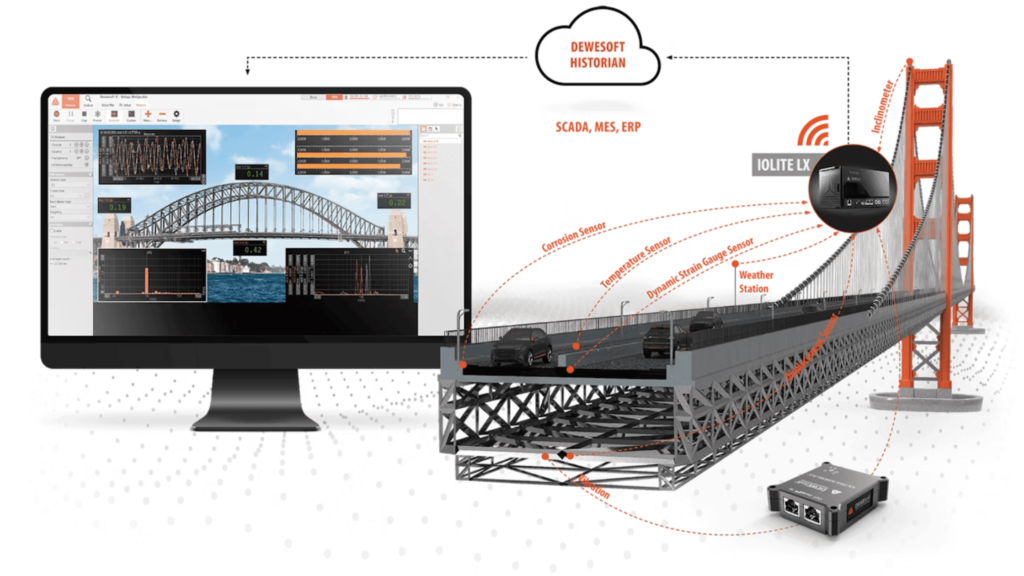

Real-time monitoring systems

Today’s bridges are getting smarter with real-time monitoring systems that use sensors to monitor their structural health. These systems can spot stress, cracks, or vibrations and send instant alerts when something’s off. With Internet of Things (IoT) technology, bridges can even send live updates straight to engineers, making it easier to catch and fix issues before they become significant problems. Not only does this boost safety, but it also saves money by tackling repairs early and avoiding sudden closures or failures.

Advanced materials for durability

New materials like ultra-high-performance concrete (UHPC) and fiber-reinforced polymers (FRPs) are shaking up how bridges are built and repaired. They’re stronger, last longer, and handle environmental wear and tear better than traditional concrete and steel. Take UHPC, for example—it’s been a go-to for replacing bridge decks because it stands up to extreme weather and heavy traffic. Plus, it’s a smart, cost-effective way to make aging bridges more durable.

Public-private partnerships

Public-private partnerships (PPPs) play a big role in completing bridge repairs. These partnerships help speed up projects and share the financial load by combining resources and expertise. Take Pennsylvania’s Rapid Bridge Replacement Project or Colorado’s infrastructure financing agreements—both show how private companies and public agencies can team up to get repairs done faster and more efficiently.

This collaboration and smart use of modern technology and materials are game-changers for bridge maintenance. By embracing these innovative solutions, the U.S. can tackle its infrastructure challenges head-on and keep its bridges safe and reliable for future generations.

Bottom line

America’s aging bridges aren’t just about transportation—they’re a safety, economic, and logistical problem that impacts everyone. The fix? Teamwork. By combining federal funding with smart collaboration between state governments and private industry, we can ensure that every dollar counts and build stronger, safer bridges for the future.

Want to stay informed about critical issues like this? Subscribe to our newsletter for the latest insights, updates, and expert commentary on the AEC industry. Let’s work together to build a brighter future for America’s infrastructure.

1 comment