From towering skyscrapers to intricate road networks, modern construction is pushing the limits of what’s possible—and the machines behind it are evolving just as fast. Automation, robotics, and AI-driven equipment are taking over time-consuming, labor-intensive tasks, making job sites safer and more efficient. Whether a robotic bricklayer working at record speed or a 3D printer shaping an entire home in hours, these innovations reshape how buildings and infrastructure come to life.

Quick look

- New machines, such as 3D concrete printers, robotic bricklayers, and autonomous excavators, are revolutionizing construction productivity, safety, and precision.

- Artificial intelligence and automation reduce labor demands, minimize human error, and streamline large-scale infrastructure projects.

- Exoskeletons and robotic assistants are helping construction workers by reducing fatigue, preventing injuries, and extending career longevity.

- Advanced machines, such as AI-powered road pavers and 3D printers, are reducing material waste, optimizing resources, and improving construction sustainability.

The role of tech in modern-day construction

Construction has always been a hands-on industry, but today, technology plays a bigger role in shaping how buildings, roads, and infrastructure come together. Machines powered by robotics, artificial intelligence, and automation are streamlining everything from heavy lifting to fine-detail work, allowing projects to move faster and with greater precision.

With labor shortages putting pressure on job sites and sustainability becoming a top priority, these innovations are more than just convenience—they’re a necessity. Robotic systems reduce worker strain, AI-driven equipment minimizes human error, and 3D printing reduces material waste while speeding up production. As the industry continues to evolve, technology is bridging the gap between traditional craftsmanship and the future of smarter, more efficient construction.

6 new machines modernizing construction

1. 3D concrete printing robots

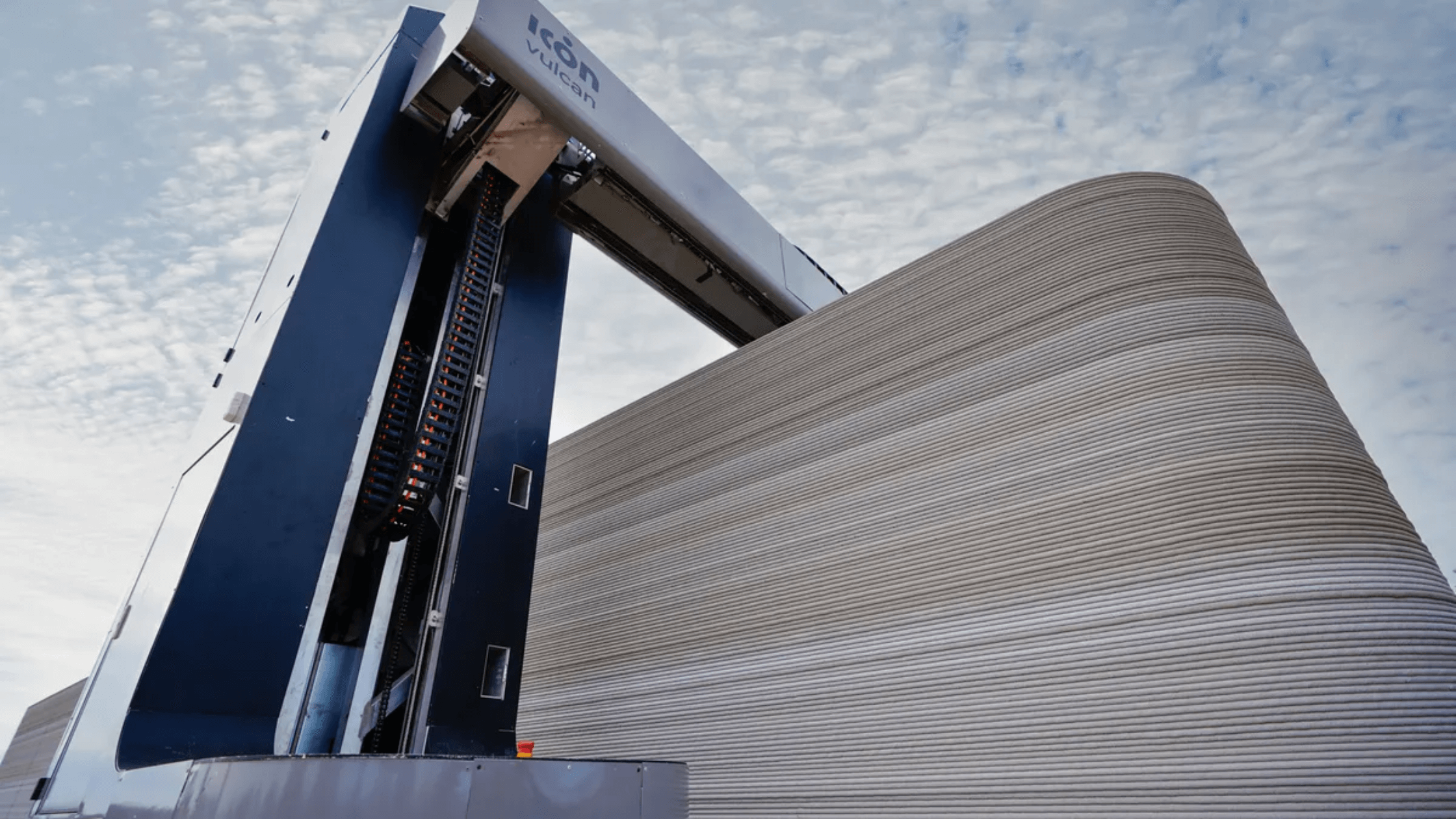

Where to find it: ICON

Building a house used to take weeks or even months, but 3D concrete printing is significantly changing that timeline. ICON’s Vulcan printer can construct a home in just 24 hours, layer by layer, using a specialized concrete mix. This automated process drastically reduces labor costs and material waste while maintaining durability and structural integrity.

These machines are making a real impact in solving global housing challenges. ICON’s technology is used for affordable housing projects, disaster relief efforts, and even experimental designs for off-world construction. By eliminating the inefficiencies of traditional building methods, 3D concrete printing is paving the way for more sustainable and accessible construction solutions.

Key features:

- Prints with cementitious materials for long-lasting durability

- Automates the building process, mitigating workforce gaps

- Creates customizable designs at scale for various housing needs

Video: ICON’s 3D Printing in Action

2. Autonomous excavators and earthmovers

Where to find it: Built Robotics

Excavation is one of the most demanding and time-consuming parts of any construction project, but AI-powered machines make it faster, safer, and more precise. Built Robotics has developed autonomous excavators that can dig, grade, and trench with minimal human input. Using artificial intelligence and GPS technology, these machines can perform complex earthmoving tasks accurately, reducing errors and costly rework.

One of the most significant advantages of autonomous excavators is their ability to work around the clock, helping construction projects stay on schedule without relying on large operator teams. By reducing the need for manual labor in hazardous environments, these machines also improve worker safety—keeping people away from potential dangers like trench cave-ins, falling debris, and extreme weather conditions. Because built robotics technology can be retrofitted onto existing equipment, companies don’t have to invest in brand-new machinery to benefit from automation.

Key features:

- Uses AI and GPS for highly accurate digging and grading

- Operates 24/7, helping projects meet deadlines faster

- Can be retrofitted onto standard excavators, making automation accessible

Video: Built Robotics Autonomous Excavator

3. Robotic bricklayers

Where to find it: FBR

The Hadrian X robot by FBR is designed to lay bricks with remarkable speed and precision. It can place up to 1,000 bricks per hour, more than human workers can achieve. This system uses advanced robotics to ensure consistent structural integrity while reducing material waste.

One of Hadrian X’s standout features is its ability to adjust in real-time using dynamic stabilization. This allows it to work seamlessly in outdoor environments where wind and other factors could otherwise affect accuracy. It integrates directly with CAD designs, enabling precise, pre-planned builds with minimal human intervention. Beyond speed, robotic bricklayers also help address labor shortages and reduce the physical strain on workers, making construction sites safer and more efficient.

Key features:

- Uses dynamic stabilization to maintain accuracy in real-world conditions

- Integrates with CAD designs for automated, precision bricklaying

- Alleviates physical strain on workers by automating heavy lifting and repetitive tasks

Video: Hadrian X in Action

4. Rebar-tying and assembly robots

Where to find it: TyBot

Tying rebar is one of the most repetitive and labor-intensive tasks in construction, but automation makes it faster, safer, and more efficient. TyBot is a fully autonomous rebar-tying robot designed to streamline bridge and road construction by significantly reducing the need for manual labor. By taking over this time-consuming process, TyBot helps construction teams stay on schedule while improving overall precision.

TyBot enhances job site safety by reducing the need for workers to bend, kneel, or operate in hazardous environments for extended periods. This is especially critical in large-scale infrastructure projects, where rebar tying is a significant bottleneck. By working continuously without fatigue, TyBot accelerates timelines and ensures consistency, making it a game-changer for modern construction.

Key features:

- Works continuously without fatigue, reducing project delays

- Improves safety by minimizing manual labor in high-risk environments

- Cuts project timelines in half, improving overall efficiency

📹 Video: TyBot Demonstration

5. Exoskeletons for construction workers

Where to find it: Hilti

Construction work often requires repetitive lifting and overhead tasks that strain workers’ bodies. Hilti’s EXO-O1 exoskeleton is designed to reduce fatigue and prevent injuries by providing mechanical assistance to the upper body, particularly the arms and shoulders. By redistributing weight and reducing muscle strain, these wearable devices help workers maintain endurance throughout the day without excessive exertion.

Unlike powered exoskeletons that rely on batteries or motors, Hilti’s EXO-O1 is entirely mechanical, making it lightweight and easy to use on-site. It seamlessly integrates into job site activities, allowing workers to move naturally while benefiting from added support. For industries mitigating workforce gaps, exoskeletons like these can help extend career longevity, keeping experienced workers in the field longer and improving workplace safety.

Key features:

- Reduces muscle fatigue and improves worker endurance

- No batteries required—relies on mechanical assistance for support

- Supports arms and shoulders, making overhead work safer and easier

📹 Video: Hilti EXO-O1 in Action

6. Automated road paving machines

Where to find it: Wirtgen Group

Laying roads with precision is a challenge, but AI-powered paving machines are making the process smoother—literally. Wirtgen Group’s automated road pavers use AI and GPS technology to ensure precise material application, reduce waste, and improve road longevity. By minimizing human error and optimizing resource use, these machines help construction teams work faster while delivering higher-quality results.

Automated paving is especially useful in large-scale infrastructure projects where consistency is key. With real-time sensor adjustments, these machines can adapt to site conditions and ensure an even, durable surface. This level of precision extends the roads’ lifespan and reduces costly repairs down the line. As governments and private companies look for ways to modernize infrastructure, AI-driven paving solutions quickly become an industry standard.

Key features:

- Uses GPS and AI sensors for real-time adjustments and precision paving

- Reduces material waste, ensuring a more sustainable road-building process

- Improves road longevity by minimizing uneven surfaces and inconsistencies

📹 Video: Wirtgen Auto Paver

Bottom line

The construction industry is undergoing a massive transformation, and these six machines are at the forefront of the change. Automating labor-intensive tasks, improving precision, and enhancing safety make construction faster, more innovative, and more sustainable. Whether AI-powered earthmovers, robotic bricklayers, or 3D printing technology, automation is reinventing the built environment.

Want to keep up with the latest in construction tech? Subscribe to our newsletter for updates on the newest innovations, industry insights, and game-changing developments in modern construction.