Autonomous technology is rapidly transforming many industries, including construction. Thanks to artificial intelligence machines like skid steers, hauling trucks, and excavators are now capable of operating without direct human intervention. These autonomous machines are slowly being integrated into construction sites to handle tasks like earthmoving, grading, and even building structures. The question however remains, just how efficient are these machines and will they become a norm to the every day construction crew?

What are autonomous machines?

Autonomous machines are self-operating systems that can perform tasks often without human intervention, guided by artificial intelligence, sensors, and advanced algorithms. These machines are designed to carry out specific functions with high accuracy and efficiency with little to no downtime, making them extremely valuable in industries that demand precision and reliability.

For instance, remote-operated electric skid steers are utilized in mining operations, offering enhanced safety and efficiency. Firstgreen’s recent initiative revealed the potential of these autonomous skid steers in improving mining safety, a key concern in hazardous environments.

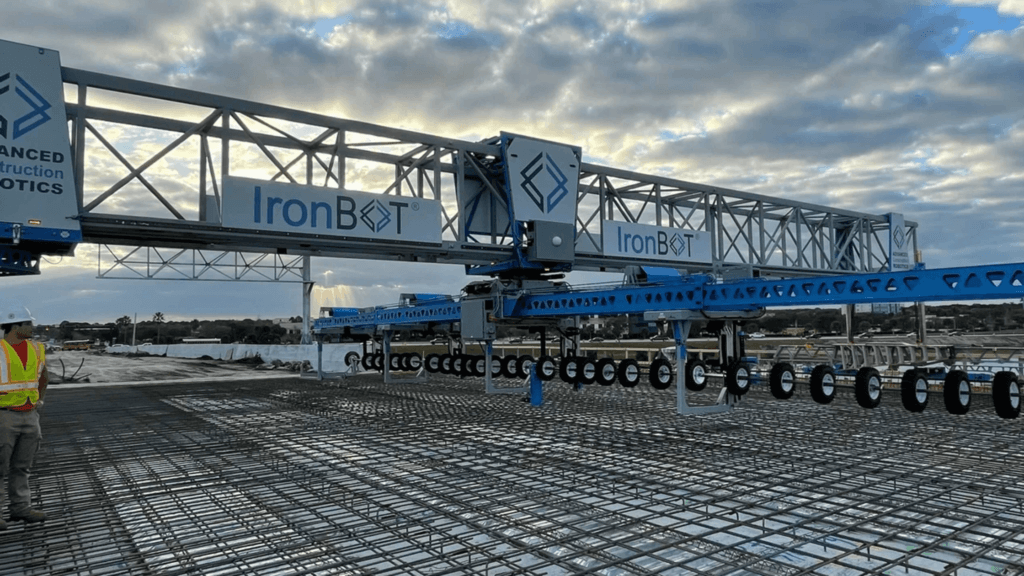

Beyond mining, construction sites are also seeing the integration of 3D printers that can construct entire buildings layer by layer, bricklaying robots capable of precisely placing thousands of bricks per day, and factory-automated machinery that contributes to constructing and assembling construction materials. These innovations are pushing the boundaries of what’s possible in construction, paving the way for safer, faster, and more cost-effective project execution.

Applications and benefits of autonomous machines in construction

Cost optimization

One of the primary advantages of autonomous machines in construction is the potential for significant cost savings. While the initial investment in autonomous equipment can be high, the long-term financial benefits outweigh this large cost. This is because autonomous machines can reduce labor costs by performing tasks that would otherwise require multiple workers, often around the clock and without the need for breaks. For example, autonomous dump trucks used in mining operations have shown that driverless vehicles can minimize delays and optimize fuel use, resulting in lower operational costs. Companies like Rio Tinto have expanded their autonomous fleet, highlighting the cost-effectiveness of these technologies.

Productivity

Autonomous machines can work continuously without breaks, handling repetitive tasks precisely and reducing the need for rework. They can also work around the clock instead of shiftwork, translating into shorter project timelines and a more streamlined construction process. Robots involved in the prefabrication of modular homes have been shown to increase production efficiency by 15% and speed by 38%, illustrating the potential productivity gains.

Greater precision

With advanced sensors and computer vision systems, these machines can perform tasks such as grading, excavation, and bricklaying with millimeter-level accuracy. This ensures that construction projects meet exact design specifications, reducing the likelihood of errors and costly modifications down the line. The ability to execute complex tasks with such precision also opens the door to innovative construction methods, such as 3D printing, which creates intricate architectural designs that were previously difficult or impossible to achieve.

Safety

Safety is a massive concern in the construction industry, where heavy machinery, complex worksites, and human error often lead to accidents. The International Labour Organization reports that construction workers are four times more likely to be involved in a fatal accident than other industries, making the safety benefits of autonomous machines even more appealing. Autonomous machines help mitigate safety risks by removing human operators from hazardous environments, as in the case of Firstgreen’s autonomous skid steers used for mining. In addition, autonomous vehicles also don’t experience fatigue or distractions, two common factors that often lead to accidents on job sites.

Will autonomous machines replace construction jobs?

Impact on employment

Despite the rise in automation, the construction industry is not expected to see a massive job loss. The unpredictable nature of construction sites, where tasks are often tailored to specific project needs and environmental conditions, means that fully automating every aspect of a job site is challenging. Instead, jobs will likely evolve, with workers needing to upskill to operate alongside automated systems. In addition, the demand for construction jobs is projected to grow globally, with up to 200 million new jobs potentially created by 2030, particularly in regions with significant infrastructure needs like Asia and Africa.

Upskilling the workforce

As autonomous machines take over more repetitive and physically demanding tasks, the role of the human worker will evolve. Many workers will need to acquire new skills to manage, operate, and maintain these advanced systems. For instance, construction workers may need to learn how to operate complex software, monitor machine performance, and troubleshoot issues that arise with autonomous equipment. This shift towards a more tech-savvy workforce could increase wages for those who successfully upskill as demand for these new skills grows.

Job creation and opportunities

As autonomous machines become more prevalent, there will be increased demand for technicians, software engineers, and other specialists who can develop, manage, and maintain these systems. Furthermore, the focus on modular construction and off-site manufacturing—areas that are particularly suited to automation—may open up new roles in factory-based construction, where workers can benefit from safer and more controlled environments.

The challenges of autonomous machines on-site: Is the technology ready?

As promising as autonomous machines in construction are for the industry, their integration on job sites is filled with challenges that raise questions about whether the technology is truly ready for widespread adoption.

Technological limitations

Autonomous construction machines operate in environments far more dynamic and unpredictable than controlled factory settings. This unpredictability makes it difficult for these machines to perform consistently without human intervention. For instance, while technologies like GPS and LiDAR allow for precise navigation, these systems struggle with real-time environmental changes, such as unexpected obstacles or varying terrain.

One example is Komatsu’s Smart Construction Initiative, which aimed to create fully autonomous bulldozers and excavators. Despite seven years of effort, significant investments, and technological advancements, these machines still required considerable human oversight. This is likely because construction tasks often involve manipulating objects in 3D in a frequently changing setting, making it challenging for the technology to adapt. So, while the experiments with fully autonomous heavy-duty machinery have started, the idea has yet to advance beyond the prototype stage.

Training and adaptation

The shift towards autonomous systems requires significant upskilling for the existing workforce. Workers must learn to operate and manage these machines, blending traditional construction skills with new technological competencies. However, this transition is not straightforward. The construction industry is traditionally slow to adopt new technologies, and there is often resistance to change. Moreover, the high demand for skilled workers capable of managing autonomous systems can create a skills gap, especially as these roles require a unique combination of construction and technological expertise.

Regulations and legal issues

The regulatory landscape for autonomous construction equipment is still evolving. Governments and industry bodies are working to establish guidelines and safety standards, but progress has been slow. One of the critical issues is legal liability—who is responsible if an autonomous machine causes an accident on-site? Until these legal questions are resolved and a clear regulatory framework is in place, companies may be hesitant to fully embrace these technologies.

Initial cost investment

The cost of adopting autonomous machines in construction remains a significant barrier. While these technologies promise long-term cost savings through reduced labor and increased efficiency, the upfront investment is substantial. Smaller companies, in particular, may find it difficult to afford this level of expenditure, especially when the return on investment is not immediate. This high cost of entry limits the widespread adoption of autonomous equipment to larger firms with the necessary capital.

Data security and reliability

As autonomous machines rely heavily on data and connectivity, data security and system reliability issues are also critical. Cybersecurity threats pose a significant risk, as even minor data breaches or system failures could lead to costly errors on construction projects. Ensuring the security and reliability of these systems is crucial to gaining broader acceptance within the industry.

Bottom line

Integrating autonomous machines in construction marks a significant shift towards more efficient, safe, and precise project execution. While these technologies offer promising benefits, they also present unique challenges that must be addressed, including technological limitations, workforce adaptation, regulatory hurdles, and significant upfront costs.

As the industry continues to evolve, the key to successful adoption will lie in striking a balance between leveraging these innovations and ensuring the workforce has the skills and knowledge to work alongside these advanced systems. By addressing these challenges head-on, the construction industry can fully realize the potential of autonomous machines, paving the way for a future where construction is more efficient, safer, and more sustainable.

About the author

Alexander Klocek is Content Director at Under the Hard Hat, a media platform focused on the construction workforce. Before managing the publication, he built a career as a content writer and copywriter, producing articles, scripts, and marketing content across health & fitness, finance, and SaaS before transitioning to media for the architecture, engineering, and construction industry.

1 comment