Scaling the construction industry’s output means recruiting a new wave of workers, but it also means significantly upgrading the tech. Founded by the team that helped bring autonomous vehicles to the streets, Bedrock Robotics is bringing self-operating machinery to sites of all types. Their goal is to implement AI to construction machines of all kinds, working safely and without interruption day and night, expanding what construction teams can achieve in all sectors of the market.

Robotics, meet self-driving tech

Waymo has been making headlines in recent years thanks to its innovations in robotics and autonomous vehicle tech. Now, those same veterans of the space have secured an $80 million funding round from 8VC and Eclipse to bring the groundbreaking technology to the construction space.

Instead of completely reinventing the wheel, Bedrock Robotics has developed a self-driving kit that can be installed and retrofitted to almost any worksite vehicle or heavy machine. They’re updating a company’s existing fleet of machines with intelligence, sensors, and software that understand the project’s goals. These machines also change and adapt to new conditions, and work without a break, around the clock.

AI software implementation that doesn’t stall your projects

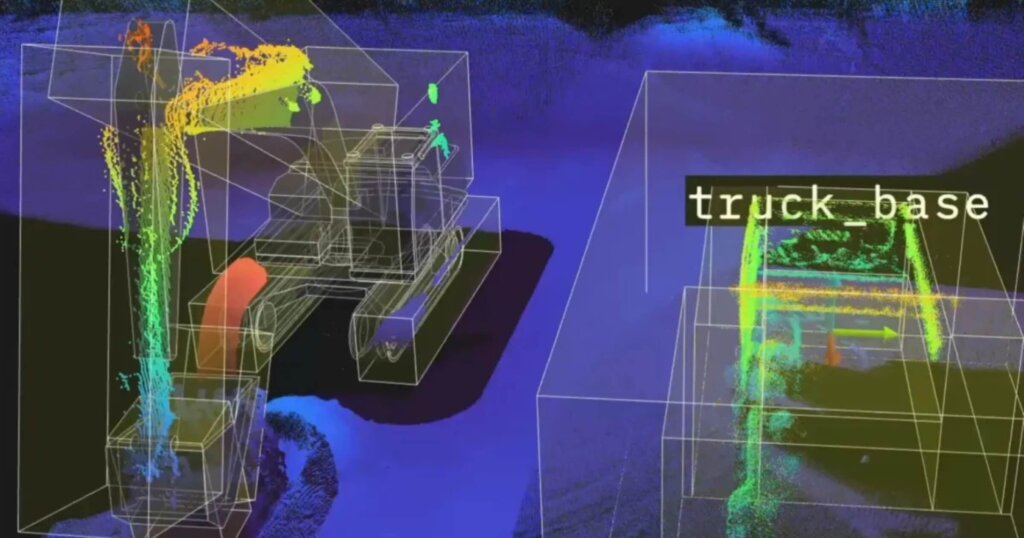

The robotics kit from Bedrock can be installed with the operator in as little as a few hours. There’s minimal downtime on site, and the kits won’t mean permanent modifications to your fleet. Here’s what the tech looks like.

- An adaptable mount: Bedrock’s mount anchors onto existing points.

- A Light Detection And Ranging (LiDAR) system: These systems scan and map a structure or landscape, providing a deep understanding of your work area.

- A multi-camera setup: There are more than eight high-definition cameras, giving the software a 360° field of view.

- A GPS + IMU: GPS and an Inertial Measurement Unit (IMU) measure a machine’s localization with granularity down to a centimeter.

And it’s all controlled by state-of-the-art compute. The brains behind the kit execute data-processing tasks and complex calculations so your fitted machine can stay on task and remain seamlessly productive.

Photo courtesy of https://bedrockrobotics.com/

Elevated safety and operational data

With autonomous vehicles, safety is a major concern for buyers and users. Bedrock ensures all vehicles have unobstructed visibility, can stop in the case of an emergency, and there’s less room for human error. It can navigate boulders, trenches, hills, and any obstacle it may encounter on site.

These machines also operate with greater precision, thanks to the large-scale machine learning AI models that are trained on a variety of projects across the United States. Users can view metrics on performance and status in real-time, and critical projects are always on task. It’s frictionless operation without sacrificing safety or quality.

Subscribe to the newsletter and follow us on LinkedIn to be notified of anything upcoming in construction and engineering tech!

1 comment