In a groundbreaking development, Benninghoven, a part of the Wirtgen Group, has unveiled the world’s first 100% green hydrogen burner system explicitly designed for asphalt production. This revolutionary system significantly reduces emissions and sets a new standard for sustainability in the industry. Unlike traditional asphalt production, Benninghoven’s innovation utilizes green hydrogen—a zero-emission fuel—offering a cleaner and more sustainable alternative.

How the green hydrogen burner system works

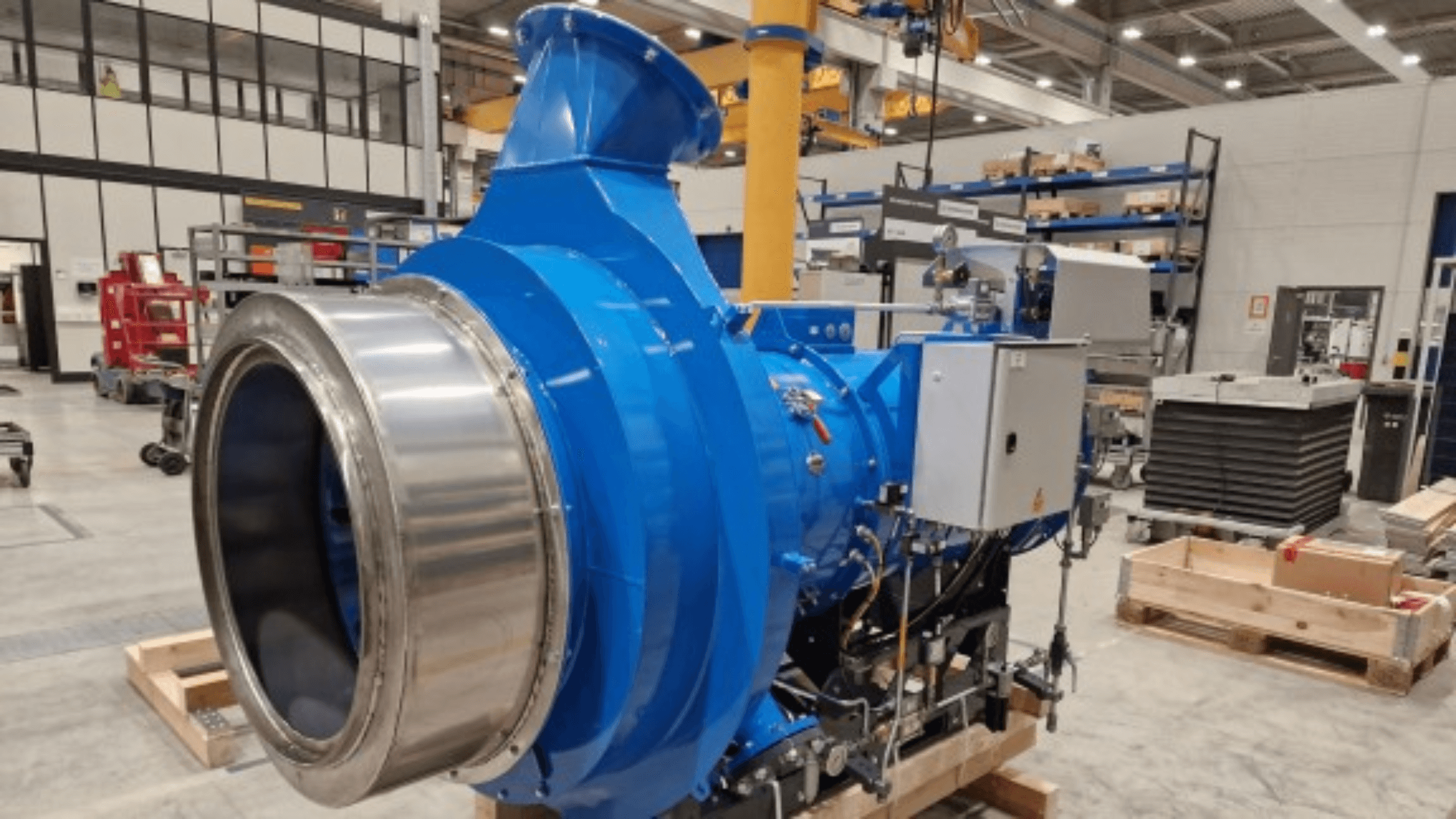

The core of this technology is a highly efficient control system that integrates the burner, fuel feed, and pressure regulation. The state-of-the-art burner can utilize up to four different fuel types, including green hydrogen. This flexibility allows plant operators to choose the most cost-effective and environmentally friendly fuel available at any given time.

This setup ensures optimal combustion and heat transfer, minimizing energy loss and enhancing overall efficiency. This prevents production downtime and stabilizes the temperature, ensuring consistent quality in asphalt production. The emissions, mainly nitrogen oxides, are kept remarkably low when hydrogen is used, making the process environmentally friendly.

Innovative features

One of the standout aspects of Benninghoven’s system is its reduced electrical power consumption—up to 20% less than traditional methods. Additionally, the system achieves a 5-decibel reduction in noise emissions, making it particularly advantageous for urban settings where noise pollution is a concern.

The compact design also enhances the system’s flexibility and usability, allowing it to be installed in both new and existing plants. Retrofit options are available, enabling older facilities to upgrade to this cutting-edge technology without a complete overhaul.

A step towards sustainable road construction

Benninghoven’s innovation is not just a technical achievement—it’s a major step towards sustainable infrastructure development. By making it feasible to use green hydrogen in a critical industrial process like asphalt production, the company is helping to reduce the carbon footprint of road construction—a sector traditionally dominated by high energy consumption and emissions.

As the world moves towards more sustainable practices, innovations like the green hydrogen burner system offer a glimpse into a future where industrial processes can be both efficient and environmentally friendly.