At CES 2026, Doosan Bobcat Inc. unveiled a new set of AI-powered products, digital displays, and modular battery packs designed to power the next generation of compact equipment. These products aim to make operating compact equipment easier and more intuitive for operators. They also aim to make them more durable and efficient in tough working conditions.

Bobcat’s primary focus has been on solving real problems for equipment users, and their latest product concepts and offerings build on that legacy. CEO Scott Park said the company is responding to changing workforce needs with intelligent systems that help people work faster and smarter. Many of the technologies on display at CES are designed to lower the learning curve for new operators while helping experienced users work with greater precision and confidence.

Bobcat Jobsite Companion

The centerpiece of Bobcat’s CES announcement is Jobsite Companion, described as the first AI-enabled feature developed specifically for compact construction equipment. This prototype system provides real-time support inside the machine, allowing operators to interact with their equipment using voice commands or simple prompts on a display.

Bobcat Jobsite Companion display demo, presented at CES 2026.. Courtesy of Doosan Bobcat Inc.

We got a firsthand look at how Bobcat’s Jobsite Companion was integrated into their latest compact equipment. Joel Honeyman, Vice President of Global Innovation at Doosan Bobcat, showcased various features during our interview at CES 2026, including how to activate the voice command feature with the push of a button and give it simple prompts.

With just a voice command, Jobsite Companion can adjust attachment settings based on jobsite conditions, offer operating suggestions, and automate more than 50 machine functions without the operator removing their hands from the controls. This presents an opportunity for operators to maximize their productivity on site and bring a new level of machine mastery.

Voice command button to activate AI-powered Bobcat Jobsite Companion. Courtesy of Doosan Bobcat Inc.

The Bobcat Jobsite Companion can also be used to teach new operators how to use the controls without ever needing to access the manual. All the operator has to do is ask. Gone are the days when you have to reach for a manual to figure out how the machine works. In addition, the system runs fully onboard the machine using Bobcat’s own AI language model. That means it doesn’t rely on cloud connectivity, which is a major advantage for remote or signal-limited jobsites.

According to Joel Honeyman, later this year, there will be limited offerings of the Bobcat Jobsite Companion for customers to purchase.

Service.AI and Collision Warning Systems

Bobcat also introduced Service.AI, an AI-powered service platform aimed at reducing downtime and speeding up repairs. This system gives dealers and technicians instant access to repair manuals, warranty information, diagnostic guidance, and past service cases. It acts like a digital master technician, guiding users step-by-step through complex repairs.

In an industry struggling with skilled labor shortages, Service.AI has the potential to make a real difference. Faster troubleshooting and clearer diagnostics mean machines can return to work sooner, which directly impacts jobsite efficiency.

Service Ai demo. Courtesy of Doosan Bobcat Inc.

Safety was another major focus. Construction is well known for workplace incidents. It has a number of high-risk hazards, constantly putting workers at risk. Bobcat’s Collision Warning and Avoidance System is a new way of looking out for the health and safety of workers.

Bobcat showcased its Collision Warning and Avoidance System, a prototype designed to actively slow or stop a machine before a collision occurs. Using imaging radar, the system tracks nearby objects and alerts the operator when a hazard is detected. If needed, it can automatically intervene to prevent any incidents. Early customer testing has already shown this system to be a strong differentiator, especially for crowded or fast-moving jobsites.

RogueX3: The most advanced autonomous compact equipment concept

Bobcat RogueX3 on display at CES 2026. Courtesy of Doosan Bobcat Inc.

Looking further ahead, Bobcat revealed RogueX3, its most advanced concept machine to date. Fully electric, with no hydraulics and autonomous, RogueX3 features a modular design that allows it to be configured with or without a cab, on wheels or tracks, and with different lift arms. This customizable approach is the next level of modular equipment for contractors, as it can adapt to various working conditions and job types. The concept has already been tested in pilots with the hope of pushing boundaries to identify where it can be used best.

While the CES version is electric, Bobcat designed the platform to support diesel, hybrid, or even hydrogen power in the future. This flexibility suggests Bobcat is thinking long-term about how compact equipment must adapt across industries and energy types.

Bobcat Standard Unit Pack (BSUP): Electric power for the future of compact equipment

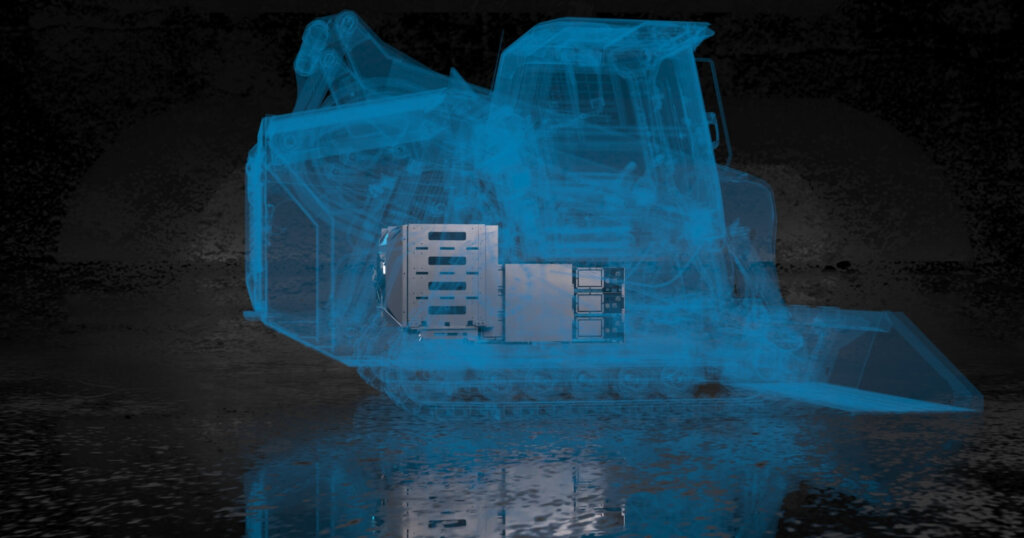

Bobcat Standard Unit Pack presented at CES 2026. Courtesy of Doosan Bobcat Inc.

Powering Bobcat’s electric vision is the Bobcat Standard Unit Pack, or BSUP. These fast-charging, modular battery packs are stackable, rugged, and scalable across different equipment types and OEM’s. They were designed to withstand the harshest working conditions and to be easily installed in various types of compact equipment.

The vision behind the BSUP goes beyond just Bobcat. These units will be available to other OEM’s to power the progress of electrification across various brands. By standardizing electric power, Bobcat is laying the groundwork for cleaner and quieter jobsites across all major compact equipment.

Bobcat’s Advanced MicroLED Display

Bobcat’s transparent MicroLED display presented at CES 2026. Courtesy of Doosan Bobcat Inc.

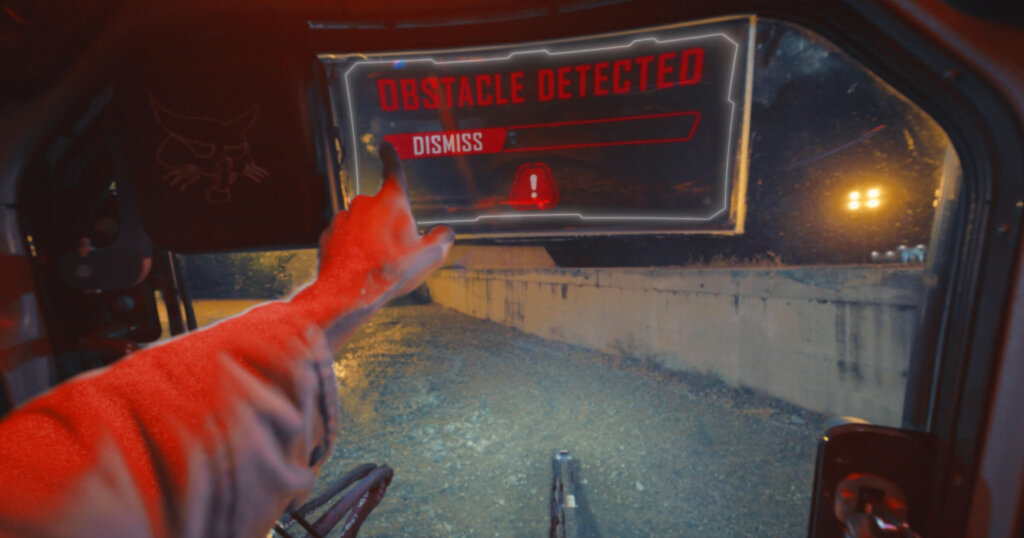

One of Bobcat’s concepts included a transparent MicroLED display integrated into the cab window. The concept display, which is still in testing, overlays machine data directly into the operator’s field of view and can be used for various functions, including:

- 360-degree camera views

- Collision warning and avoidance alerts

- Jobsite feature display

- Real-time machine performance data

- Real-time visual asset tracking and monitoring

The use cases are promising, especially on large construction sites that have complicated terrain. Maps of known terrain can be uploaded and displayed, giving the operator confidence to navigate in tricky areas. If you need performance data, the display can show you what state the machine is in and what you can do better next time to improve efficiency. The display is touch-activated just like any smartphone, making it intuitive for operators. It also comes with an auto-tint feature.

Bobcat’s vision of the future

Taken together, Doosan Bobcat’s CES 2026 announcements signal a shift toward machines that actively assist the people using them. Rather than adding complexity, these technologies aim to simplify work, improve safety, and expand who can confidently operate advanced equipment. While many of the systems are still prototypes, their direction is clear. Bobcat is building an ecosystem where AI, autonomy, and electrification work together, setting a new benchmark for the future of compact construction equipment.