Whether you’re working on a foundation, driveway, or slab, pricing concrete jobs right keeps your business profitable. The process of calculating the total cost starts with accurate measurements and then moves through material costs, labor, equipment, and markup. Each step affects the bottom line, and missing just one can cost you. This guide walks you through how to price concrete jobs with real-world precision, whether you’re working solo or managing a crew.

Step-by-step process for pricing a concrete job

Measure the project site

To get the price right for your concrete foundation, everything starts with accurate measurements. Concrete projects require you to measue the square footage of the area you want to pour so you can have the correct concrete volume per cubic feet to get an accurate estimated cost. Use a laser or tape measure to calculate the length, width, and depth of the pour area. Always measure twice as one bad number throws off the whole bid. For slabs, multiply length × width × depth (in feet), then convert to cubic yards by dividing by 27. Round up slightly to account for spillage or over-excavation.

Pro tips:

- Use digital tools or apps to keep measurements consistent

- Account for slopes or irregular shapes with extra volume

- Double-check plans against field measurements

Calculate material and delivery costs

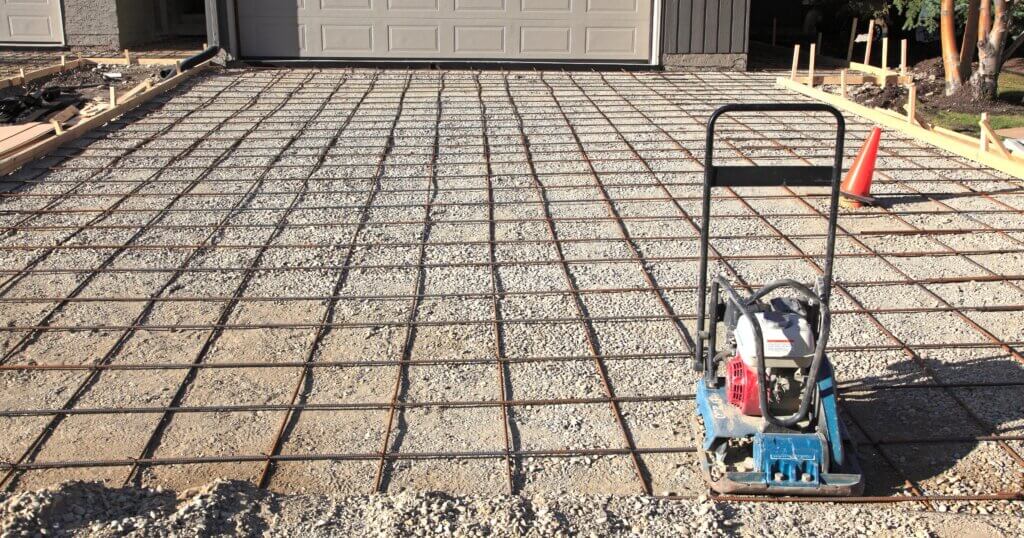

Now that you know the volume, estimate how much concrete you’ll need. Concrete prices vary by region and supplier, but most concrete runs between $120–$150 per cubic yard. Don’t forget to add in transportation costs, which can spike if the job is in a remote area or requires multiple trips. You may also need additives or reinforcement like rebar, wire mesh, or fiber mesh.

Pro tips:

- Always include 5–10% extra for waste

- Check if you’ll need concrete pumps or special mix designs

- Get written quotes from suppliers to lock in pricing

Estimate labor time and cost

Basic labor costs depend on crew size, experience, and how complex the job is. A slab might take a few hours while a large concrete foundation with fiber mesh and rebar takes more time and skill. Estimate how many hours of labor the job will require, then multiply by your hourly labor rate. If you’re hiring subcontractors, include their rates. It’s also a good idea to factor in breaks, setup, and cleanup time.

Pro tips:

- Include time for forming, pouring, finishing, and curing

- Higher wage markets mean higher pricing expectations

Include equipment and tool usage

Concrete work needs more than a wheelbarrow and shovel. Pumps, mixers, vibrators, screeds, trowels, and safety gear should all be factored in. If you own the equipment, calculate wear-and-tear costs. If you’re renting, include the full rental rate and delivery fees. Even smaller tools like bull floats and edging tools can add up, especially on large projects.

Pro tips:

- Include fuel costs for mixers, saws, or generators

- Plan for extra equipment if you’re on a tight timeline

- Use past job records to estimate realistic usage

Add overhead and markup

Once you’ve tallied materials, labor, and equipment, it’s time to add overhead and profit. Overhead covers business expenses like insurance, licenses, office costs, and truck maintenance. A good rule is 10–20% for overhead and 10–20% for profit markup but adjust based on competition and market demand. Skipping this step eats into your profit margins fast.

Pro tips:

- Keep overhead estimates consistent across all jobs

- Track past jobs to dial in your average profit margins

- Don’t underprice to win work—it can hurt long-term growth

Provide a detailed quote to the client

Now package everything into a clear, professional quote. Break it down into labor, materials, equipment, overhead, and final price. Include notes about payment schedules, timelines, and any exclusions. A good quote builds trust and helps clients understand your value. Use estimating software or templates to keep it polished and consistent.

Pro tips:

- List line items separately for transparency

- Include expiration dates on your quotes (usually 30 days)

- Always get the client’s signature before starting work

Key factors that affect the price of concrete jobs

Site preparation requirements

If the site isn’t ready, your costs go up fast. Surface preparation can include grading, demolition, soil testing, compacting, and drainage fixes which will turn a small job into a labor-intensive project. Rocky ground, tree roots, or poor access can slow things down and require extra equipment. Walk the site with the client early on and ask detailed questions about what’s been done and what still needs to be done. Take photos and notes so you can later provide a rough estimate on site prep.

Ways to manage this:

- Include a line item for site prep in your quote

- Consider a contingency buffer for unknowns

- If possible, partner with a local excavation crew for reliable estimates

Labor costs

The cost of labor fluctuate based on location hourly rate, experience level, union involvement, and the difficulty of the pour. Complex layouts, slopes, or tight schedules can drive labor hours up quickly. Bad weather and high demand can stretch your timeline, too. It’s easy to underestimate labor so make sure you leave some room for error.

Ways to manage this:

- Build in weather buffers during colder or rainier seasons

- Use time-tracking from past jobs to estimate more accurately

- Always confirm crew availability and rates before finalizing your bid

Equipment and tool expenses

The right tools make the job smoother—but they come at a cost. Specialized concrete equipment like pump trucks, screed machines, ride-on trowels, or vibrators can add hundreds (or thousands) to a job, especially if rented. If you own the gear, factor in fuel, maintenance, and wear and tear. Skipping the right tool to save money can lead to delays or quality issues.

Ways to manage this:

- Know which tools are essential vs. optional for each job

- Compare rental vs. ownership cost over time

- Include equipment use as a separate line item in your quote if possible

Finishing work and add-ons

Basic broom finishes are fast. Decorative finishes? Not so much. Stamping, staining, exposed aggregate, polished concrete, and sealing all require extra hours and skilled labor. These services not only cost more but also raise client expectations. Never roll them into a general quote—if the scope changes mid-job, you’ll eat the cost.

Ways to manage this:

- Quote all specialty finishes separately

- Have visual examples ready to show clients what each finish entails

- Get the client to sign off on the exact finish before starting

Permits and inspections

Local rules vary, but most municipalities require some form of permit for new concrete work—especially if it affects public property like sidewalks or driveways. These permits often come with inspection requirements that could delay the job or require plan adjustments. Skipping this step can cost you fines or forced rework.

Ways to manage this:

- Call the building department before quoting the job

- Build permit and inspection costs into the proposal

- Keep digital copies of all approvals on-site

Overhead and profit margin

There’s more to running a concrete crew than showing up and pouring. Your truck, phone, insurance, admin hours, estimating time, advertising, and accounting software all cost money. These overhead expenses need to be baked into every job or they’ll eat your profit without you noticing.

Ways to manage this:

- Calculate your monthly overhead and break it down per job

- Set a consistent markup on materials and labor

- Review your net profit per job regularly—not just gross revenue

Bottom line

Pricing concrete jobs takes planning and a sharp eye for detail. Every square foot and cubic yard has costs tied to labor, materials, equipment, and overhead. Missing just one of these steps can hurt your profits or cost you the job. Use this guide as a step-by-step plan to stay competitive and profitable in today’s concrete market.

For more real-world advice for tradespeople and contractors, subscribe to our newsletter at underthehardhat.org/join-us.