Builders, architects, and innovators are rethinking what it means to build something strong, smart, and sustainable. Across job sites and labs alike, a wave of next-gen materials is unlocking new possibilities, from walls that heal themselves to concrete that bends under pressure instead of breaking. These materials are already changing how we build, what we build with, and how long it lasts. In this article we cover the latest innovative construction materials you’ll likely be seeing in the future of construction.

1. Transparent wood

Image courtesy of renovablesverdes.com

While it looks like something out of a sci-fi movie, transparent wood is real, and it’s changing the face of sustainable design. KTH Royal Institute of Technology’s scientists in Sweden developed the material by removing lignin, the part of wood that gives it its color and rigidity, and replacing it with a transparent polymer. The result is a durable, see-through wood that lets in light while retaining its strength and insulation properties.

Transparent wood could change the face of sustainable design. Unlike glass, it softens and diffuses light, cutting down on glare while offering better insulation. That makes it a smart option for windows, skylights, and even full building façades. And because it’s made from renewable materials, it gives eco-conscious builders a greener alternative that doesn’t sacrifice performance.

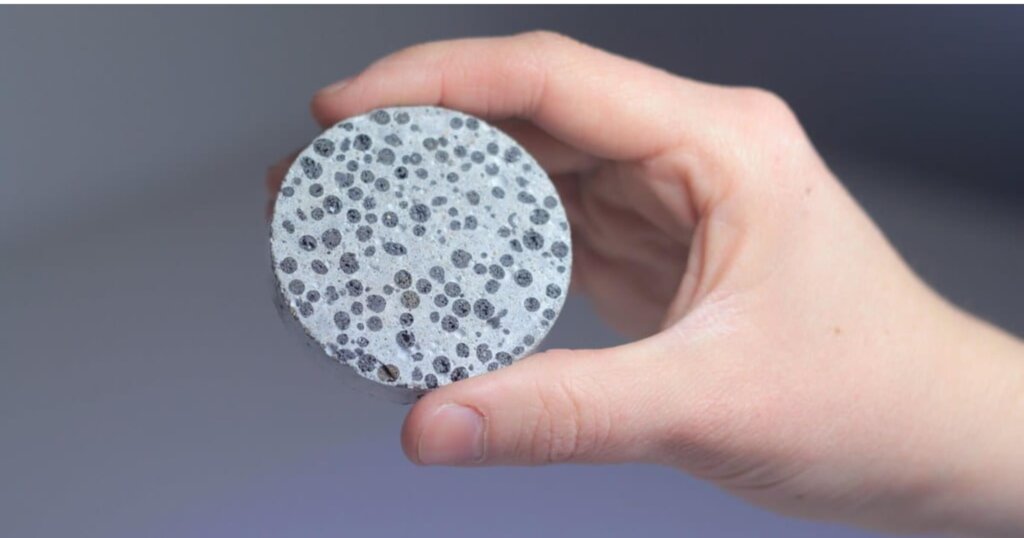

2. Self-healing concrete

Image courtesy of https://voices.uchicago.edu/

Cracks are a concrete structure’s worst enemy, but what if the material could repair itself? Self-healing concrete does just that. It’s made by mixing special bacteria or chemical healing agents into the concrete mix. When cracks form and water seeps in, these agents activate and produce limestone or other sealants that fill the gaps automatically, without human intervention.

Self healing concrete is especially valuable for infrastructure that suffers from wear and tear over time, such as roads, bridges and tunnels. It extends the life of the structure, cuts down on repair costs, and improves safety. With cities around the world facing aging infrastructure, self-healing concrete offers a proactive solution that saves money and reduces disruptions.

3. Bendable concrete (engineered cementitious composite)

Traditional concrete is strong but brittle; it can crack under tension or extreme movement. Bendable concrete, also known as Engineered Cementitious Composite (ECC), changes that. Developed by Dr. Victor Li at the University of Michigan, this high-performance material is reinforced with tiny polymer fibers that allow it to flex and bend without breaking, much like metal.

This flexibility makes it an ideal solution for earthquake-prone regions or projects requiring long-lasting durability. ECC is also more resistant to weathering and shrinkage, which means fewer cracks and a longer lifespan for everything from bridges to buildings. By absorbing stress rather than fracturing, bendable concrete is setting a new standard for resilient construction.

4. Transparent aluminum (aluminum oxynitride or ALON)

Image courtesy of Shutterstock

Technically known as Aluminum Oxynitride or ALON, transparent aluminum is a ceramic compound composed of aluminum, oxygen, and nitrogen. The result is a material with exceptional durability and a crystal-clear appearance. It’s significantly harder than glass and can withstand extreme conditions without cracking or shattering.

Because it’s lighter and stronger than traditional bulletproof glass, ALON is already being explored for use in military vehicles, spacecraft, high-rise buildings, and secure facilities. Its ability to offer both visibility and high-impact resistance makes it a perfect choice for next-gen safety and design applications.

5. Bio-coal lining

Image courtesy of https://terrapretaorganics.com/

Bio-coal lining is a promising green alternative in the world of high-emission industries like steel and cement production. Made by converting agricultural waste into a carbon-rich material through a process called torrefaction, bio-coal acts as a sustainable lining for kilns and furnaces.

Because it’s carbon-negative (unlike traditional fossil fuels), this innovation addresses two major problems simultaneously: agricultural waste disposal and industrial emissions. By turning plant waste into a valuable construction asset, bio-coal lining helps decarbonize some of the dirtiest parts of the building process, while also providing farmers and waste processors with a new revenue stream. It’s a smart, circular solution with long-term impact.

6. Hemp rebar

Image courtesy of https://www.case.rpi.edu/

Made from woven hemp fibers and often bonded with a bio-resin, this innovative construction material is incredibly strong, lightweight, and resists corrosion, making hemp rebar a sustainable alternative to traditional steel reinforcement in concrete.

As a renewable resource that grows rapidly and requires minimal inputs, hemp rebar is an eco-friendly choice for sustainable builders. As more construction teams seek low-impact materials without compromising on strength, hemp rebar is emerging as an incredible reinforcement option.

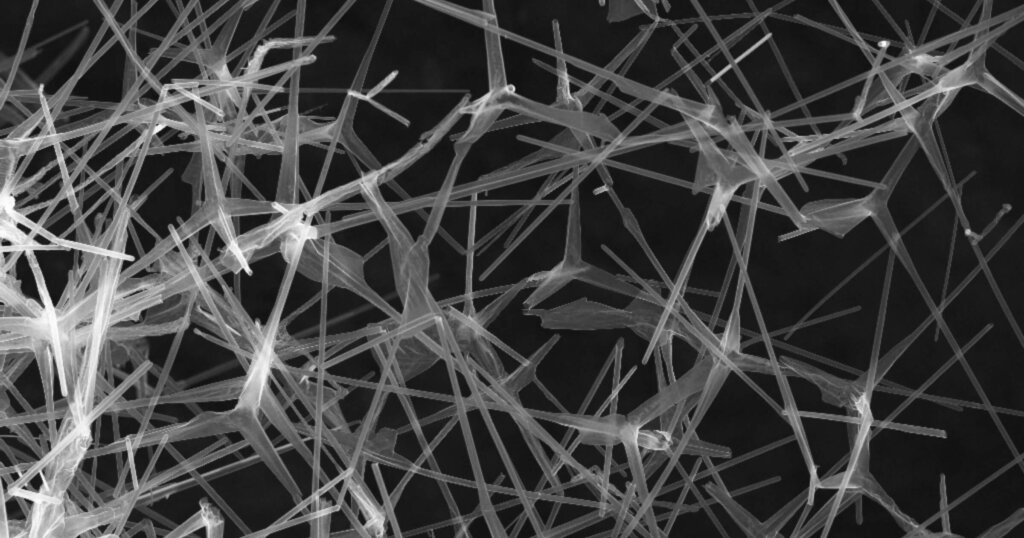

7. Aerographite

Image courtesy of wikipedia.com

Developed by researchers at Kiel University and Hamburg University of Technology, Aerographite holds the title of one of the lightest materials ever created, weighing just 0.2 milligrams per cubic centimeter; about 75 times lighter than Styrofoam.

Despite being almost impossibly light, aerographite is tough. It can be compressed by up to 95% and still bounce right back to its original shape, which makes it great at handling stress and absorbing vibration. It’s also electrically conductive, so beyond construction, it has potential in things like sensors and batteries.

In building applications, aerographite could become useful for lightweight panels, insulation, and high-performance composites. Because it’s strong without being heavy, it can help cut down on structural load and transportation costs.

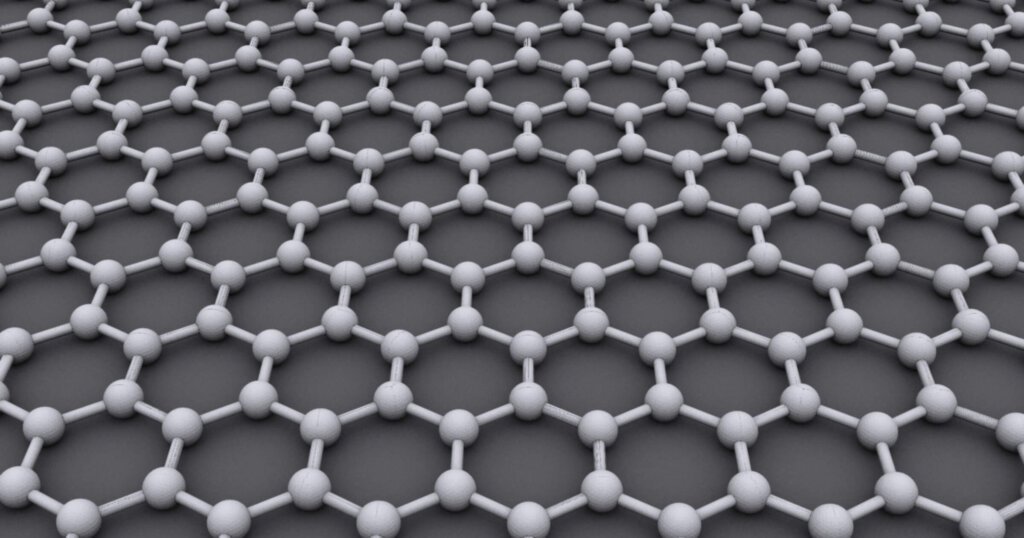

8. Graphene

Image courtesy of Wikipedia.com

Graphene is a single layer of carbon atoms arranged in a hexagonal lattice, and it’s making big waves in construction by being added to concrete mixes. When infused into traditional concrete, graphene significantly improves the material’s mechanical properties. It creates a denser, more durable structure that requires less cement and water, all while reducing the concrete’s carbon footprint.

Studies show graphene concrete can be up to 30% stronger and use 50% less material without compromising integrity. It’s also more resistant to water and chemical damage, which means longer-lasting roads, buildings, and bridges.

Because it can be integrated into existing concrete production systems, graphene-enhanced concrete is innovative and highly scalable, an important quality for widespread adoption in both small-scale and large infrastructure projects.

9. Mycelium insulation

Mycelium insulation is an innovative construction material that’s eco-friendly compared to traditional insulation. Derived from the root-like structures of fungi, mycelium is cultivated by introducing fungal spores into organic waste substrates like sawdust or straw. Over several days, the mycelium grows, binding the substrate into a dense, foam-like material. Once fully formed, it’s heat-treated to halt further growth, resulting in a rigid, biodegradable, fire-resistant insulation panel.

Mycelium insulation brings a lot to the table that traditional materials don’t. It’s non-toxic, naturally resistant to mold, and does a great job with both sound and temperature control. Companies like Ecovative Design have been leading the way in turning this fungus-based material into something builders can actually use, tailoring it for different shapes, sizes, and needs.

Because mycelium grows by absorbing carbon, it helps pull carbon out of the air. It’s a rare case where the material itself is both high-performing and actively good for the planet. Not bad for something that starts in the dirt.

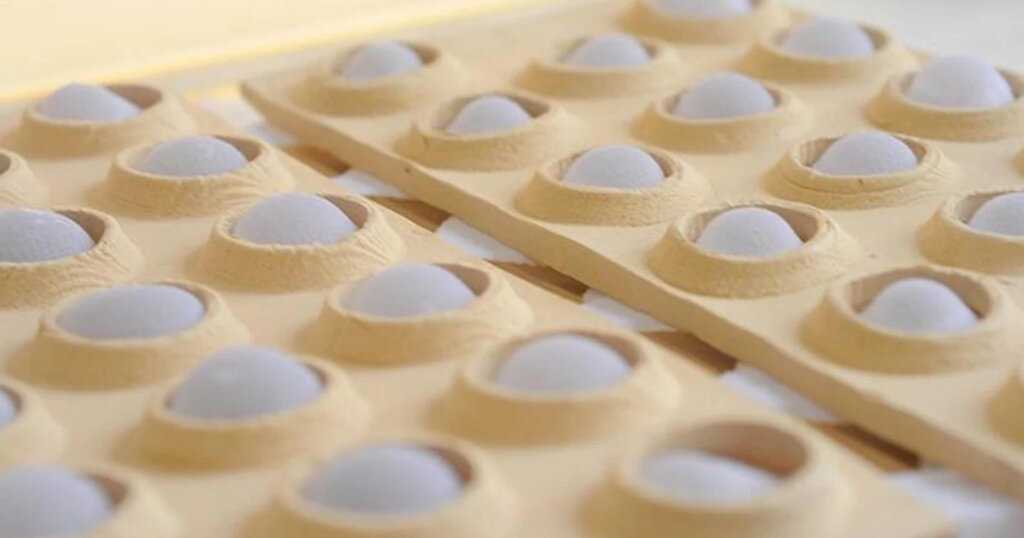

10. Hydroceramic bricks

Image courtesy of https://www.re-thinkingthefuture.com/

Hydroceramic bricks offer a smart, low-tech way to keep buildings cooler, especially in hot climates. Created by students at the Institute for Advanced Architecture of Catalonia (IAAC), this innovative construction material blends classic clay brickwork with modern materials to deliver a sustainable, energy-free cooling solution.

These bricks are made by blending traditional clay with hydrogel, a material that can soak up as much as 500 times its own weight in water. When the temperature climbs, the water slowly evaporates, pulling heat out of the surrounding air in the process. The result is a noticeable cooling effect inside the building, up to 6°C (or nearly 11°F), all without relying on air conditioning or electricity.

Using hydroceramic bricks offers several advantages:

- Energy efficiency: These bricks can lead to significant energy savings by reducing reliance on air conditioning.

- Sustainability: Made from natural and readily available materials like clay and hydrogel, they present an eco-friendly alternative to conventional cooling systems.

- Adaptability: The bricks can be customized in various shapes and sizes, making them suitable for different architectural designs and applications.

This innovative approach to building design addresses the challenges of rising temperatures and contributes to the development of sustainable and energy-efficient construction practices.

11. Light-generating concrete

Image courtesy of https://www.futurly.com/

Imagine sidewalks, bike paths, and highways that glow softly after sunset, without using a single watt of electricity. Thanks to the groundbreaking work of Dr. José Carlos Rubio Ávalos at Mexico’s Michoacan University of San Nicolás de Hidalgo, this vision is becoming a reality. He developed a phosphorescent cement that absorbs sunlight during the day and emits a gentle glow for up to 12 hours at night, offering a sustainable alternative to traditional lighting.

The innovation lies in modifying the microstructure of cement to eliminate the crystalline components that typically block light. By creating a gel-like, non-crystalline structure, the cement allows light to penetrate and be stored within. This stored energy is then gradually released as visible light in the dark. The material is currently available in blue and green hues, with brightness levels adjustable during production to prevent glare.

Beyond its aesthetic appeal, light-generating concrete has practical applications in enhancing nighttime visibility in areas where reliable electricity is unavailable. Its production is environmentally friendly, emitting only water vapor during manufacturing, and the material boasts a lifespan of up to 100 years.

12. Shape-memory alloys (SMAs)

Image courtesy of https://www.azocleantech.com/

Shape-memory alloys (SMAs) are a category of smart materials that can “remember” their original shape. After being deformed, they return to their pre-set form when exposed to a specific temperature. Often made from nickel-titanium (NiTi) alloys, these materials have unique molecular structures that rearrange under stress and then snap back into place, much like a spring with built-in memory.

In construction, SMAs are being explored for use in earthquake-prone regions. When embedded in bridges, buildings, or structural joints, they can absorb and dissipate seismic energy, allowing the structure to flex and recover without cracking or collapsing. This resilience reduces the risk of catastrophic failure and the need for costly repairs after an event.

13. Cigarette-butt bricks

Cigarette butts are the most commonly discarded waste item globally, with over 6 trillion cigarettes produced each year, leading to 1.2 million tonnes of toxic waste dumped into the environment. Researchers at RMIT University have developed a method to recycle this waste by incorporating cigarette butts into fired clay bricks. By adding 1% cigarette butts to the brick mixture, the resulting bricks are as strong as conventional ones but require less energy to produce.

The inclusion of cigarette butts not only reduces the density of the bricks by up to 30% but also enhances their insulation properties. This makes them lighter and better at retaining heat, which can lead to energy savings in buildings constructed with these bricks. Moreover, the high calorific value of cigarette butts contributes to energy savings of up to 58% during the brick firing process.

If just 2.5% of global annual brick production incorporated 1% cigarette butts, it could offset the total cigarette production each year, presenting an innovative construction material to a pervasive pollution problem.

Bottom line

From transparent wood to waste-powered insulation, innovative construction materials are being build every year, and they’re changing everything from how we build to how long structures last. Whether you’re focused on sustainability, resilience, or innovation, these materials represent the next generation of construction.

For weekly updates on the most exciting construction innovations, subscribe to our newsletter and never miss a beat.