In 2016, frustrated by the expense and inefficiency of road repairs, a team of lecturers, inventors, and entrepreneurs from the University of Liverpool’s School of Engineering put their heads together to devise a better solution. The result is Robotiz3d, a company that plans to reinvent road repair with a little help from AI-driven robots.

Solving the pothole problem

Potholes are a nuisance to cyclists and drivers and a maddening recurring expense for many cities. According to Robotiz3d, potholes cost US drivers $26 billion a year, while UK drivers foot the bill for £1.7 billion in yearly pothole-related expenses. These road repairs are not only costly but also time-consuming —the average timeline for a road repair in the UK is a staggering 15 months.

Founded by Liza Layzell, Paolo Paoletti, and Sebastiano Fichera, Robotiz3d was created to address these problems. Using patented research from the University of Liverpool’s Engineering Robotics lab, the team has created autonomous technology capable of detecting, preventing, and repairing cracks and potholes.

Robotiz3d currently has three distinct road repair solutions: ARRES Eye, ARRES Prevent, and ARRES Ultra (under development).

ARRES Eye

The ARRES Eye can be installed on existing city vehicles like buses and garbage trucks. It is designed to detect, map, and categorize cracks and potholes by scanning lanes one by one with its 3-meter (9.8 feet) field of view.

The Eye catalogs each road defect with detailed information and prioritizes repair work based on size, location, and severity, making workflows a breeze. The device can collect data while traveling up to 60 mph and functions day or night in any weather.

ARRES Prevent

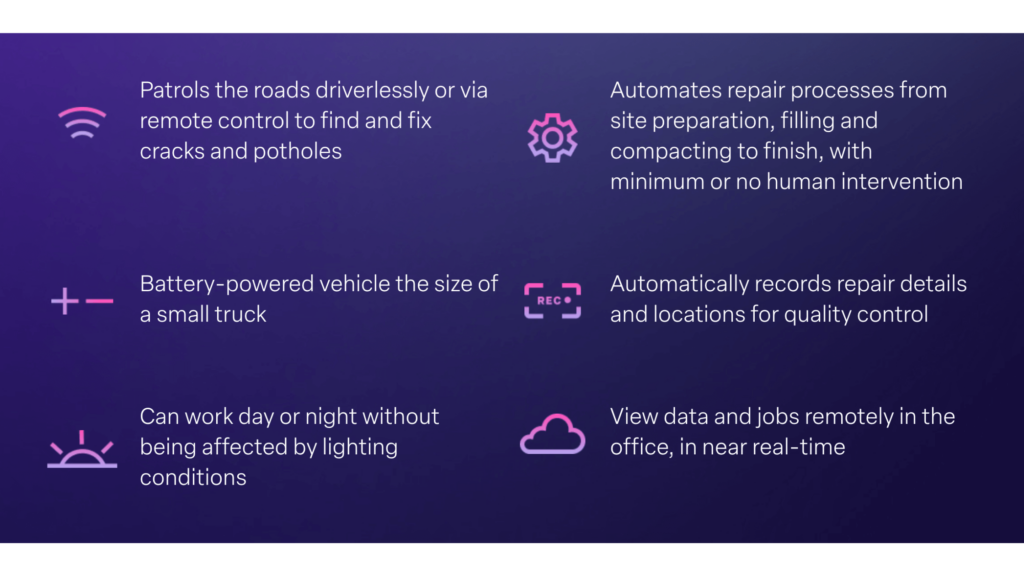

The ARRES Prevent is a battery-operated vehicle the size of a small van. It can be operated with a remote control or in driverless mode and can be run in any weather, day or night.

The Prevent uses the technology of the ARRES Eye to identify cracks in the road and then repairs them, sealing them before they become potholes. This vehicle has completed its first trial out of the lab and is currently undergoing more field testing.

ARRES Ultra

Currently in development, the Ultra goes one step beyond the Prevent and can repair potholes and smaller cracks. Its fully autonomous process includes preparing the site, filling and compacting the defect, and recording repair details. Like the Prevent, the Ultra can be operated remotely or in driverless mode, and though it’s the size of a small truck, it still runs on battery power.

Taking robotic repair for a test drive

In March of this year, the Robotiz3d team took the ARRES Prevent out of the lab and onto the streets of Potter’s Bar, Hertfordshire, to see how the technology would perform in a real-world environment.

The Prevent (which looks a little like a Tesla Cybertruck, with a blunt nose and flat panels arranged in angles along the body) passed its field test with flying colors. It successfully identified and filled cracks in the streets, which will prevent water from seeping in and creating potholes.

A smarter way to manage roads

Robotiz3d’s solutions are packaged as “Robot-as-a-Service” (RssA), meaning that municipalities don’t have to purchase the robotic vehicles upfront. Robotiz3d also takes care of both hardware and software maintenance. This offers an attractive option to the costly and time-consuming road repair systems in most cities.

While field testing is still underway and the ARRES Ultra is still under development, the company is confident that local governments will see the benefits of their AI-driven road repair technology.

Robotiz3d Technical Director Dr. Sebastiano Fichera said, “Current methods to detect and repair of potholes are labour intensive and as such are slow, unsafe, and costly to the economy and environment. The new technology we are developing will make road maintenance tasks faster, cheaper, and cleaner and ultimately make roads safer and more accessible.”

2 comments