Construction workers face some of the highest risks on the job, whether they’re framing rooftops, operating heavy machinery, or navigating busy worksites. Every year, thousands of injuries stem from just a handful of preventable causes called the fatal four. Knowing what those hazards are and how they happen is the first step in keeping crews safe and job sites running smoothly.

Quick look:

- Falls, struck-by incidents, electrocutions, and caught-in/between accidents account for nearly 60% of construction fatalities annually.

- Improper use of ladders, missing fall protection, and poor training make falls the deadliest hazard on construction sites.

- Lack of training, misuse of personal protective equipment (PPE), and cutting corners to meet deadlines contribute to recurring, preventable accidents.

- Ongoing training, proper equipment, regular inspections, and effective top-down leadership can significantly reduce job-related injuries.

What are the most common construction injuries?

Falls, struck-by incidents, electrocutions, and caught-in/between accidents. These incidents consistently rank at the top of the list; in fact, OSHA refers to them as the “Fatal Four”. Together, they account for more than half of all construction-related fatalities each year.

According to OSHA data, the Fatal Four were responsible for nearly 60% of construction worker deaths in 2022, with falls alone making up more than one-third of those fatalities. The fatal four are everyday risks tied to common job site activities.

What makes them so persistent?

In many cases, it’s a combination of fast-paced work, inconsistent safety practices, and preventable oversights. Tasks such as working at heights, operating machinery, and handling electrical tools all come with inherent risks. Still, these risks are amplified when corners are cut, PPE is ignored, or safety systems fail to meet their standards.

The good news is that these injuries are largely preventable. With the right training, tools, and safety culture in place, companies can reduce incidents dramatically and keep workers protected where it matters most.

Falls

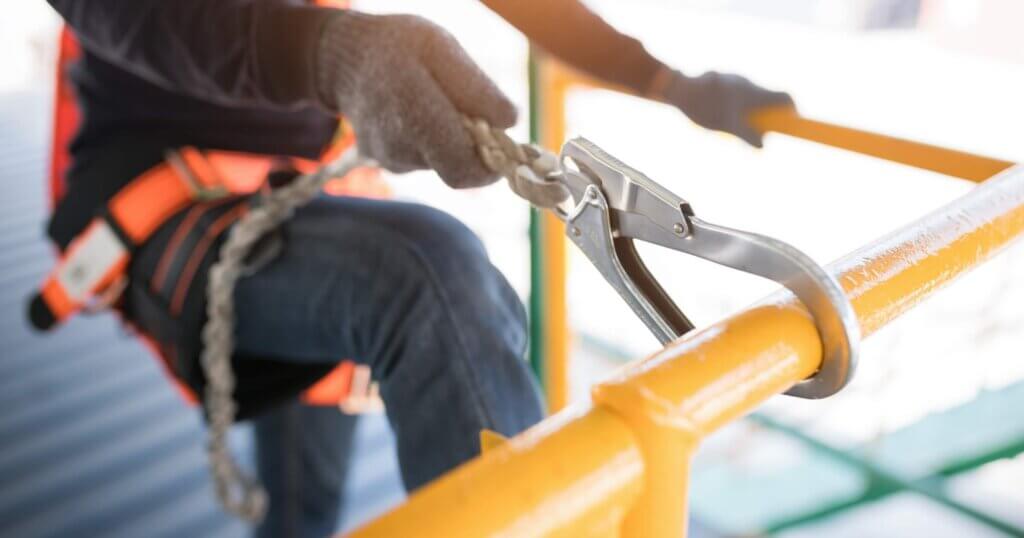

Falls are the number one cause of construction fatalities—and they’re also some of the most preventable. Most often, these incidents occur when workers are on roofs, ladders, or scaffolding without proper safety equipment. Whether it’s a misstep near an unguarded edge or a harness that’s not clipped in, a moment of oversight can lead to devastating consequences.

Common culprits include unsecured ladders, lack of fall arrest systems, poor training, and damaged or improperly installed guardrails. According to the Bureau of Labor Statistics, falls accounted for 395 of the 1,069 construction fatalities in 2022. That’s more than one fatality per day, just from falls.

Struck-by incidents

Getting struck by objects is another leading cause of injury and death on job sites. These incidents can involve anything from falling tools and flying debris to equipment or vehicles that move without warning.

Dropped tools from above, swinging crane loads, or dump trucks backing up without a spotter are just a few common examples. Hard hats help, but they’re not a fail-safe when heavy equipment or sharp materials are involved.

Electrocutions

Electrical hazards aren’t always visible, which can make them lethal. Many construction workers are exposed to electricity on a daily basis, whether through the use of power tools, extension cords, or faulty wiring. And when something goes wrong, the results can be immediate and fatal.

Exposed wiring, ungrounded equipment, damaged cords, and working too close to power lines are all frequent sources. Even minor oversights, like using a power tool in a wet area, can turn into a deadly mistake.

Caught-in/between accidents

Caught-in or between incidents occur when workers get pinned, squeezed, or crushed between objects, such as machinery, equipment, or collapsing structures. These accidents are particularly common during trenching, excavation work, and operations involving heavy machinery.

A trench collapse, a worker pinned between a wall and a forklift, or a malfunctioning piece of equipment can all result in life-threatening injuries. Without proper shoring, guarding, and emergency protocols in place, these situations can escalate fast.

Why the fatal four injuries keep happening

If the Fatal Four are so well known—and so preventable—why are they still claiming lives year after year? The truth is, it’s not just about knowing the risks. It’s about how safety is prioritized (or not) on site.

One of the most significant issues is inconsistent or insufficient training. New workers may not receive the full rundown on hazards, while seasoned crews might not receive regular refresher training. Without updated training, even experienced workers can develop bad habits or overlook changes in safety protocols.

Then there’s the pressure to hit deadlines. In an industry where time is money, some crews cut corners by skipping putting on harnesses, rushing site prep, or ignoring inspections to stay on schedule. That drive to finish fast can come at the cost of doing it safely.

Complacency is another silent threat. The more familiar a task becomes, the easier it is to underestimate the risk. Workers start to think, “I’ve done this a hundred times—nothing’s ever gone wrong,” until the one time it does.

And while PPE is essential, it only works if it’s the right gear, in good condition, and used properly. Too often, workers aren’t provided with adequate equipment, or don’t wear it because it’s uncomfortable or slows them down.

Lastly, the sheer pace and intensity of construction work mean crews are constantly exposed to hazards. That high-risk environment, lacking strong safety systems, leaves too much to chance.

How to reduce the incidence of fatal four injuries

Preventing serious injuries is about turning safety into a daily habit. From training and inspections to leadership and accountability, here’s how construction companies can take significant steps to protect their teams.

1. Invest in consistent safety training

Safety isn’t a one-and-done lesson. Crews require regular training that extends beyond the basics, incorporating real-life scenarios, hands-on practice, and up-to-date guidance from OSHA and other regulatory bodies. Whether it’s refresher courses or onboarding sessions, making training a regular part of the job keeps safety top of mind.

2. Make PPE use mandatory and accessible

If workers don’t have access to the proper protective gear—or if the gear is worn out, uncomfortable, or optional—it won’t be used properly. High-quality PPE should be provided to every worker, for every job, and its use should be non-negotiable. That means hard hats, harnesses, gloves, high-vis vests, and everything in between.

3. Conduct regular site inspections

Daily walkthroughs and scheduled inspections help catch problems before they turn into emergencies. From loose scaffolding to exposed wiring, proactive inspections can identify hazards early and reduce the risk of incidents.

4. Create and enforce clear safety protocols

Job sites run more smoothly when everyone knows the rules. Clear signage, checklists, and standardized procedures help make safety second nature. But protocols only work if they’re enforced, so supervisors need to lead by example and hold teams accountable.

5. Promote a culture of safety from the top down

Leadership sets the tone. When managers prioritize safety, not just as an afterthought, crews are more likely to follow suit. This means budgeting for safety, discussing it in meetings, rewarding good practices, and incorporating it into the company’s core values. When safety starts at the top, it filters down to every corner of the site.

Final thoughts

The “Fatal Four” are still taking lives year after year, not because the risks are unavoidable, but because safety too often takes a backseat to speed, cost, or routine. Preventing serious injuries on the job requires a culture shift, where safety is integrated into every conversation, every plan, and every task on site.

When companies commit to consistent training, proper gear, clear protocols, and strong leadership, the results speak for themselves: fewer injuries, better morale, and safer job sites for everyone.

Want more tips, updates, and resources that put worker safety first? Subscribe to our newsletter and stay connected.