If you want to know what’s next for construction (and safety) tech, Oshkosh Corporation gave a clear answer at CES 2026. On January 6–9 in Las Vegas, Oshkosh demonstrated new tools powered by autonomy, AI, connectivity, and electrification to make tough jobs safer and more productive.

At CES, the company spotlighted technology built for “everyday heroes,” including construction workers, firefighters, airport ground crews, and more. “We are showcasing our vision of the job sites, neighborhoods, and airports of the future and how Oshkosh’s advanced technology empowers everyday heroes with safe, intuitive, productive, and clean solutions,” said Oshkosh CEO and president John Pfeifer. “Together with our customers, we’re transforming how we live, move, and work.”

This matters right now because many job sites still rely on manual, disconnected workflows that often lead to slow communication, reactive maintenance, and even missed safety risks. Oshkosh’s innovations will connect equipment, people, tools, and data into a single smart ecosystem so machines do the work rather than just assist.

JLG Boom Lift with robotic capability

One of the biggest highlights was Oshkosh’s JLG boom lift concept, which modifies a traditional lift into something closer to a jobsite robot. This autonomous system is designed to perform repetitive and high risk tasks such as welding, inspection, component placement, and maintenance without requiring an operator working in a basket at height. With the proof of concept now complete, their vision of the JLG Boom lift goes further than just these tasks.

Electrified JLG Boom Lift on display at CES 2026.

According to Louis Bafile, senior techinician fellow from OshKosh “By showing people that this machine can weld at this height, other jobsite tasks that are less sensitive can be performed as well which can include painting and cleaning of the exterior of buildings.” The goal is to find partners in these fields and begin to apply these modifications to the commercially available JLG Boom Lift to bring adaptability and further usage for contractors.

The autonomous Ai technology powering the JLG Boom Lift can also connect to jobsite management systems and digital twins, so the machine can “understand” what’s happening on the project and align tasks with the plan. This transforms a traditional boom lift to a scalable robotic partner that is able to perform a variety of tasks on a jobsite.

This kind of equipment could reduce risky work at heights and help crews get more done in less time, which is a big opportunity for contractors dealing with ongoing skilled labor shortages and tight deadlines. Adding to it’s already impressive features, it comes fully electrified, reducing noise pollution and emissions for those seeking greener solutions.

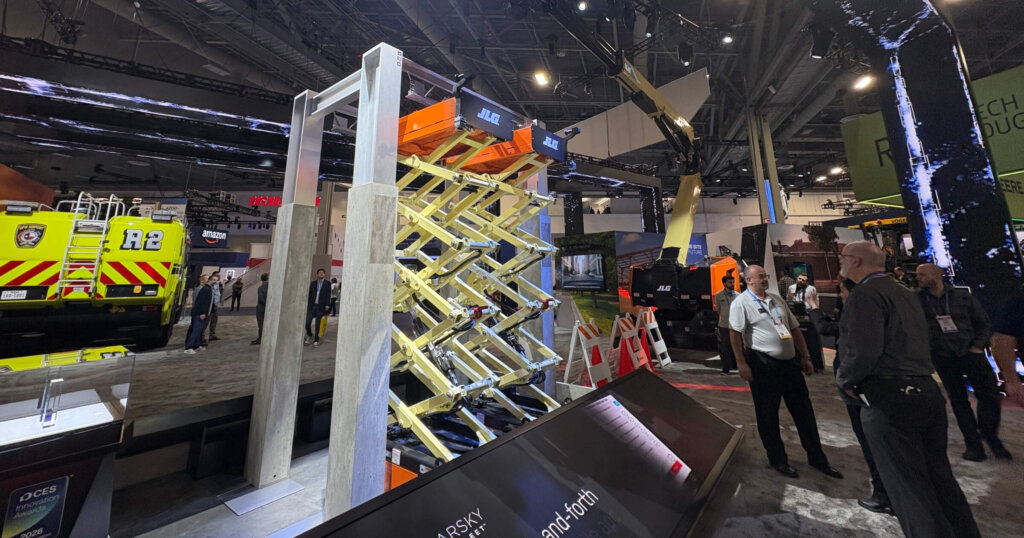

JLG Micro-Sized Scissor Lifts

JLG micro-sized scissor lifts working in tandem with the JLG Boom Lift during a demo at CES 2026.

JLG unveiled these micro sized scissor lifts alongside the JLG Boom lift. They come with what JLG calls leader-follower technology, allowing a single operator on a lead scissor lift to control multiple scissor lifts to move equipment simultaneously. They can also lift materials to a specified location, such as an I-beam, and let the JLG Boom Lift know it’s ready to be welded and in position. This allows the JLG Boom Lift to work in tandem with the scissor lifts using the ClearSky™ Smart Fleet technology communication systems. OshKosh believes these are the perfect solution for helping build data centres be built more efficiency as they often space-constrained sites with high ceilings.

Collision Avoidance Mitigation System (CAMS)

Oshkosh also earned a 2026 CES Picks Award from TWICE for its Collision Avoidance Mitigation System (CAMS), a safety technology built for roadside responders.

CAMS uses AI-fused radar and computer vision to detect and track oncoming traffic. It constantly measures things like speed, trajectory, and distance, then gives audible alerts when it detects a collision risk. It also includes in-cab camera integration to boost driver awareness and capture video for documentation.

Oshkosh says it has already field-tested CAMS with big-city fire departments over the past year and is now scaling for EMS, police, and tow operators.

“We created CAMS with a clear mission: to protect those who protect us,” said Oshkosh executive vice president and CTO Jay Iyengar. “It’s the first technology of its kind in the fire industry and purpose-built for the risks firefighters and other responders face daily. CAMS utilizes AI to not only react to roadside hazards, but to help anticipate them.”

Additional Innovations Showcased by Oshkosh at CES 2026

Beyond these, Oshkosh Corporation showcased a wide range of innovative and robotic products coming to your city streets or airport runways.

- AI-powered contamination detection for refuse and recycling vehicles: This technology uses onboard cameras and edge AI to identify non-recyclable materials at the point of collections to provide actionable data to municipalities and haulers. In turn, this info can be used to educate customers and drive behavioural change.

- HARR-E autonomous electric refuse robot: This robot now features an updated two-piece design for easier waste transfer to central dumpsters, along with built-in measurement of waste volume and weight. The system uses AI-optimized routing to efficiently handle multiple pickup requests and is designed for shared environments.

- Striker® Volterra™ electric airport rescue and firefighting vehicle. Is a high-performance electrified ARFF that delivers 28% faster acceleration with reduced emissions. This year it took home top honors at the 2026 CES Innovation Awards.

- Autonomous airport support robots: This modular fleet of robots is designed to assist ground crews with repetitive ramp and airfield tasks, helping improve turnaround times, reliability and operational efficiency in all conditions.

Industry impact

If Oshkosh’s work is any indication, the future of tough work is connected, automated, and electric. Robotic lifts could cut down on high-risk construction tasks and reduce delays. CAMS could improve roadside safety by preventing some of the most dangerous roadside incidents. This technology has the potential to be scaled in various sectors and industry fields which is why it’s so exciting. Safety is a top concern on the jobsite, regardless of whether you’re a firefighter or a welder working at heights.

If these systems roll out at scale, they could reshape how job sites plan work, protect workers, and handle increasing labor gaps.

Want more CES tech spotlights like this? Subscribe to our newsletter for weekly updates on the innovations shaping construction, safety, and the future of work.