Affordable housing is hindered by skilled labor shortages and massive construction costs. To address these challenges, Promise Robotics is pioneering innovative solutions that blend cutting-edge robotics, AI, and modular construction techniques to transform residential building processes and make housing accessible.

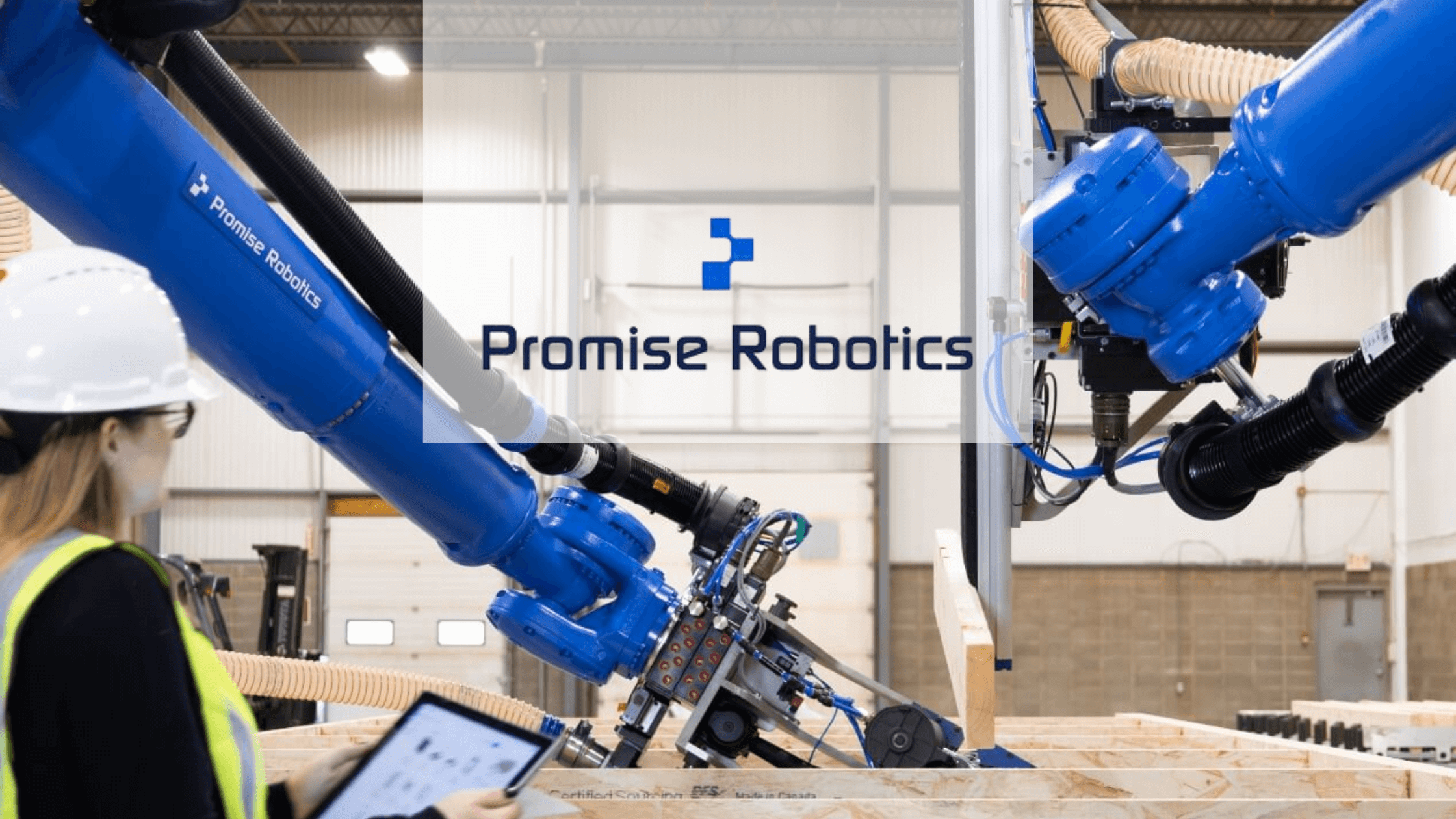

Toronto-based startup Promise Robotics is reshaping home construction by integrating advanced automation into every stage. The AI company has developed a cloud-based industrial production platform for robotic construction and assembly. Their system combines robotics and AI-driven software to streamline the production of modular housing components in a controlled environment. This approach enhances precision, minimizes material waste, and accelerates project timelines.

Making a difference in residential construction

Promise Robotics is redefining prefabrication by empowering builders to leverage AI and automation for smarter, more efficient construction. Their innovative approach centers on advanced, compact industrial robotic systems powered by a proprietary cloud-based platform. This platform manages every aspect of the production process—from planning and factory floor operations to scheduling and logistics—streamlining the entire construction lifecycle.

At the heart of their innovation is the Homebuilding Factory-as-a-Service™ concept, which provides homebuilders with access to cutting-edge expertise and technology, enabling them to accelerate the building process significantly. This approach can reduce on-site assembly times by up to 70% compared to traditional methods. For example, a single-family home can be assembled in five hours, while a 64-unit, three-story apartment building can be completed in two weeks without sacrificing quality.

A significant advantage of Promise Robotics’ system is its ability to minimize waste. Traditional construction methods generate significant material waste, but the company’s precise robotic technology optimizes material usage, contributing to sustainability efforts in the industry. This feature is particularly timely, given the increasing focus on greener construction practices.

“Informed by completing more than 10 million sq. ft. of housing, we offer a holistic and transformative production solution to address labour shortages, save costs, reduce waste, and significantly increase the speed of quality home production from single-family to multi-storey buildings,” Promise Robotics says.

The platform represents a promising future for residential construction, where technology bridges the gap left by a shrinking skilled workforce. The company is redefining construction jobs and attracting tech-savvy talent by automating repetitive tasks and allowing human workers to focus on higher-value roles. This shift not only helps fill immediate labor gaps but also redefines the workforce by creating opportunities for tech-savvy workers interested in robotics and construction technology. Their focus on collaboration, sustainability, and efficiency makes Promise Robotics a key player in shaping the future of homebuilding.

As the demand for housing grows, solutions like Promise Robotics’ innovative approach will play a vital role in creating a more resilient and sustainable construction industry. By blending advanced technology with proven results, they’re setting a new standard for building homes—faster, smarter, and affordable.

Stay informed on the latest innovations in construction technology and industry trends—subscribe to our newsletter today!