While the construction industry’s labor shortage continues to be a detriment to many job sites, it’s fortunate that it’s happening as construction robot use begins to rise. These machines learn and apply skills across a range of construction areas, and their development is driven by the need to meet demand, boost efficiency, and cut overhead costs. In this article, we’ll dive into the applications, benefits, challenges, and trends around robotics in construction.

Quick look

- Construction robots handle tasks such as operating heavy equipment, performing repetitive job-site tasks, and conducting site surveys and inspections.

- The momentum sparks from labor shortages, advancements in tech, and site safety pressures.

- Benefits include reliable quality, reducing injuries and fatalities on site, and long-term cost savings.

- Companies like Built Robotics, Canvas, and Boston Dynamics are at the forefront of robotics development.

- Best practices for implementation include training the workforce in waves, starting with pilot projects, and integrating robotics earlier in project planning.

What is construction robotics? And what are construction robots?

Construction robots include robots, cobots, and autonomous machines. They execute work using automation, machine learning, and artificial intelligence (AI), and differ in how they work with human workers. Robots are typically fully automated systems designed to operate independently. These machines perform tasks with accuracy and precision.

Collaborative robots (cobots) are designed to work in tandem with humans, helping with tasks that require shared space, agility, and human involvement. Autonomous machines go a step further by using decision-making algorithms, sensors, and AI power to adapt to changing job sites, all with minimal human intervention.

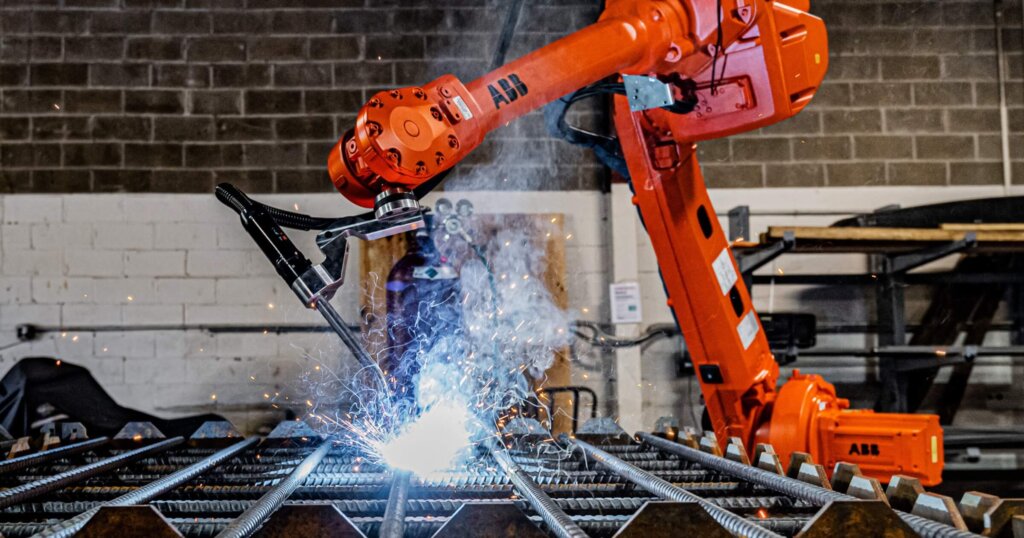

Toggle Robotics rebar robot in the middle of welding. Photo courtesy of Toggle Robotics.

Here’s how a few of these machines are used within various sectors of construction:

- Heavy equipment construction automation: This includes semi-autonomous or autonomous excavators, bulldozers, and hauling trucks. These robots use GPS, AI, LiDAR, and sensors to operate with minimal operator intervention.

- Job site tasks: Day-to-day tasks are handled by construction robots and cobots, each designed to execute specific, precision-based tasks. These machines could act as bricklayers, welders, rebar tyers, or lift and assemble materials with human assistance.

- Surveying and inspection: These robots include rovers and drones and use sensors such as LiDAR, GPS, and cameras to monitor job progress, map terrain, and detect safety issues and defects. These robots automate data collection and produce digital twins for quality assurance and project status tracking.

Why is robotics in construction rising now?

Labor shortages and the aging workforce

The most notable rise in the use of construction robots is driven by a shortage of skilled labor in the construction industry. With fewer professionals entering the trades and many retiring, robotics helps fill critical gaps.

Automated systems and on-site robots handle repetitive tasks and physically demanding work. This allows construction businesses to assign real workers to bigger-picture tasks that move the project forward.

Safety pressures and site risk

Job sites can be dangerous. By bringing in more robots to handle risky jobs, companies effectively reduce human exposure to unsafe environments. This can include having robots work at high elevations, in confined spaces, or having them use AI to do the heavy lifting. This improves compliance with safety regulations and lowers incident rates in the long run.

Advances in sensors, AI, autonomy, perception, and navigation

Modern cobots and robots use high-resolution sensors, machine learning, and computer vision to traverse unpredictable job sites and scale self-driving construction machines. These enhancements to the technology make autonomous operation more reliable and long-term cost-effective.

Integration with digital tools like BIM and digital twins

Not only do robotic products work well independently, but they also integrate seamlessly with your digital tool stack. They connect with modern Building Information Modeling (BIM) software and digital twin systems, enabling workers to gain live insights, achieve precision execution, and automate their feedback loops. This connects the digital and physical environments for faster iteration and greater productivity.

Competitive advantage, cost pressures, and productivity demands

With rising construction demand, labor and material costs are rising, and margins are tightening. By leveraging robotics technology, construction firms can pave the way for greater efficiency, less rework, and faster project delivery. This creates a decisive edge in an increasingly competitive market.

Benefits and impacts of robotics automation on job sites

Efficiency and productivity gains

Robots, unlike humans, don’t need to take breaks. They can work long hours, maintain the same level of performance, and even speed up repetitive tasks such as layout, bricklaying, and welding.

Robots minimize project downtime and coordinate with digital plans for stronger, more reliable execution. Companies can stay on schedule and meet project completion deadlines.

Safety standards and health improvements

By having robots take on dangerous activities like excavation, demolition, or work at heights to install solar panels, workers aren’t exposed to risks and hazardous environments as often. This means fewer incidents, injuries, and fatalities on the job. This also means reduced fatigue and better long-term health for workers.

Quality and consistency

Cobots and robotics systems follow pre-programmed parameters with consistent precision, reducing human error and ensuring uniformity across tasks. This improves project quality, reduces modifications and rework, and aligns with digital plans.

Economic and operational impacts

Of course, integrating robotics requires quite the upfront investment, but it will lower costs in the long run by reducing downtime, waste, and incident-related expenses. They also help construction firms operate more predictably, so workforce gaps and deadlines are met as expected.

Innovative firms use robots, offering “robot-as-a-service” as a part of their business model. This sends the message that the company is efficient, reliable, and at the forefront of technology.

Examples and use cases of robotics in the construction industry

Autonomous heavy machinery: Built Robotics converts regular dozers and excavators into autonomous systems using retrofit kits equipped with AI, LiDAR, and GPS. This enables them to automate digging and grading without a human operator.

Built Robotics autonomous excavator and team. Photo courtesy of Built Robotics.

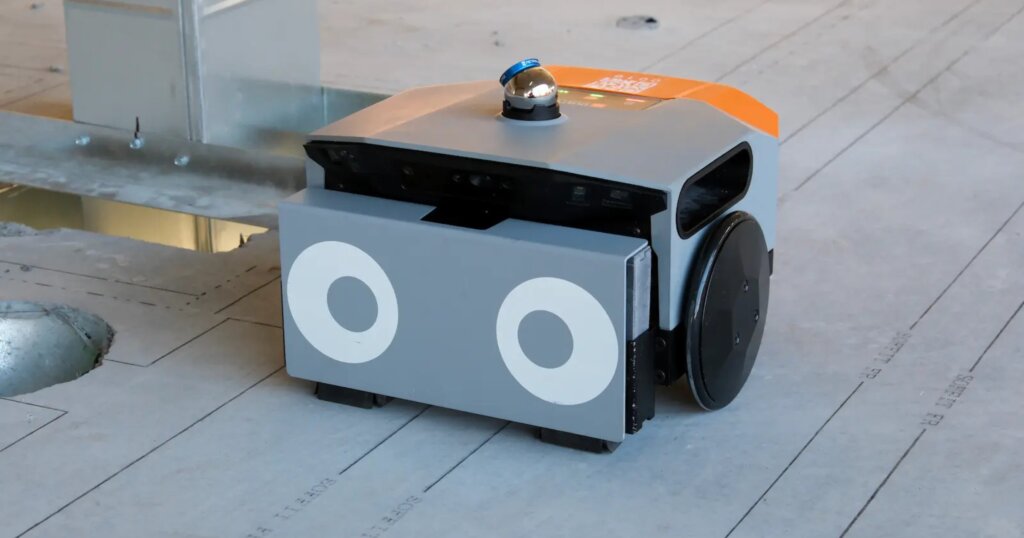

Layout and site marking robots: Dusty Robotics’ FieldPrinter autonomously prints full digital floor plans onto slabs. It effectively marks doorways, wall lines, and mechanical layouts with precision down to the millimeter.

Dusty robotics fieldprinter at work printing digital floor plan on concrete slab. Photo courtesy of Dusty Robotics.

Bricklaying and masonry robots: The SAM100 from Construction Robotics works with masons by mapping and placing bricks, and applying mortar up to 3x quicker than a manual worker. This boosts consistency and repeatability while reducing fatigue.

Construction Robotics SAM helping workers lay down bricks for a wall. Photo courtesy of Construction Robotics.

Drywall installation and finishing robots: Canvas offers a robot that finishes drywall. It sands, applies joint compound autonomously, and produces smooth finishes while keeping workers away from high-dust environments.

Canvas robot helping workers with drywall finishing. Photo courtesy of Canvas Build.

Inspection, monitoring, surveying drones & robots: DJI Matrice offers a new drone series, and Boston Dynamics’ Spot robot is widely used for job site mapping, scanning, and progress tracking. They collect data with LiDAR, cameras, and thermal sensors.

Spot robot by Boston Dynamics at a construction site reviewing progress. Photo courtesy of https://www.fosterandpartners.com/

Challenges and barriers to adoption

While robotics use boosts site efficiency and project quality, it doesn’t come without challenges. Here’s what companies should keep in mind before fully investing in a fleet of robots and cobots.

- Dynamic, unstructured site conditions: Construction sites are constantly changing, making it hard for some robots to navigate new terrain, obstacles, and spontaneous human activity.

- Safety, regulation, and standards for robots in field settings: There are currently few clear industry standards and regulations around robotics use. This creates uncertainty and potential liability concerns.

- High capital costs, maintenance, and ROI uncertainty: The upfront costs of cobots and robots, plus maintenance, software updates, and worker training time, make the short-term or total investment unclear.

- Integration and interoperability with existing workflows: Many job sites use older legacy systems and manual processes. This makes it challenging to connect newer robots to BIM technology and other digital construction tooling.

- Worker trust, training, and human–robot interaction issues: Many workers hesitate to use and work alongside robots, due to unfamiliarity and fear of job displacement.

- Scalability and variability across geographies: Construction firm codes, practices, and infrastructure vary by state or country, so robotics often requires local adaptation and customization before it can be operational.

Best practices for implementation

Getting started with Robotics doesn’t have to be overwhelming. By breaking it down into implementation phases, any construction crew can adapt and learn, and have the machines on site quickly.

Start with pilot projects and low-risk tasks

Test your robot’s capabilities with dummy projects and test tasks. By taking time to confirm it operates as expected on low-risk tasks, crews can move it to real work, such as envelope assembly and 3D printing, with greater trust and confidence.

Integrate planning early

Anticipate working with your robots earlier on in the construction project. Let it learn the familiar paths and the site conditions before it gets down to work.

Train the workforce and manage change culture

Train your workforce in waves or smaller groups, ensuring you can give most workers one-on-one time to ask questions. The more each worker becomes familiar with new technology, the more comfortable they will be in adopting and embracing change.

Partner with robotics vendors and adopt leasing models

Instead of diving headfirst into brand-new robotics purchases, work with reputable vendors to implement leased models. This helps workers on the change curve and helps teams confirm the ROI in the early stages.

Monitor metrics: time savings, error reduction, and safety outcomes

When the robots are in use, monitor how the implementation is going. Measure how much time your crew is saving versus the manual work, note how many errors it’s making, and compare incident reports to similar projects with an all-human workforce.

Bottom line

While robotics is transforming construction sites around the world, it doesn’t come without challenges. As momentum builds on your job sites, make sure you’re training, piloting, and integrating your machines early on. Then you’ll find improved efficiency, reduced injury risk, and a competitive edge.

Follow Under the Hard Hat on LinkedIn, and don’t forget to subscribe to the newsletter to stay in the loop about the latest in construction tech.