Delays, cost overruns, and logistical nightmares—construction projects are notoriously difficult to plan and execute efficiently. With so many moving parts, even the best-laid schedules can crumble under unexpected disruptions, material shortages, or labor constraints. But what if there was a way to test thousands of potential project outcomes before ever breaking ground? ALICE Technologies’ AI-powered construction optioneering platform helps builders explore multiple scheduling scenarios, identify the best path forward, and adapt to real-world challenges—all while cutting costs and saving time.

Quick look

- ALICE Technologies’ construction optioneering platform uses AI to generate and evaluate thousands of project scenarios, helping teams optimize schedules, reduce costs, and minimize risks.

- ALICE allows construction teams to adapt to real-time challenges by continuously adjusting project plans for maximum efficiency.

- Major projects, such as the HS2 Colne Valley Viaduct, have successfully implemented ALICE, achieving faster timelines and significant cost savings.

- With AI-driven predictive analytics and automation, optioneering is becoming essential for the industry’s shift toward smarter, data-driven decision-making.

Understanding construction optioneering

When it comes to large-scale construction projects, planning is everything. Traditional scheduling methods often lock teams into a single approach, leaving little room for flexibility. Construction optioneering flips that script. Instead of relying on a fixed timeline, this AI-driven process generates and analyzes thousands of possible project schedules, identifying the most cost-effective and efficient way to complete the job.

Think of it like a construction GPS, rerouting around potential roadblocks, optimizing resource allocation, and ensuring crews work smarter—not harder—while maintaining quality and safety standards. For contractors, developers, and project owners, this means better decision-making, reduced risk, and a final product that meets deadlines and budgets without unnecessary stress.

Traditional planning vs. optioneering

For decades, construction scheduling has relied on rigid, single-scenario planning. Most scheduling tools allow teams to create detailed project timelines, but making changes can be a logistical nightmare once a schedule is set. If material delays, weather disruptions, or labor shortages occur, teams are left scrambling to adjust, often leading to costly setbacks.

Construction optioneering takes a different approach. Instead of committing to one fixed plan, it explores thousands of possible scenarios, evaluating different sequences, resource allocations, and scheduling strategies. With AI-powered modeling, project managers can instantly compare options and pivot when challenges arise without wasting time on manual rescheduling.

It’s the difference between plotting a single route on a map versus using a GPS that continuously updates based on real-time conditions. By embracing optioneering, construction teams can find the smartest, most efficient way to complete a project—before ever breaking ground.

The role of ALICE Technologies in construction optioneering

Founded in 2015 based on research from Stanford University, ALICE Technologies has emerged as a trailblazer in construction optioneering. Their mission is to revolutionize how construction projects are planned and executed by harnessing the power of artificial intelligence.

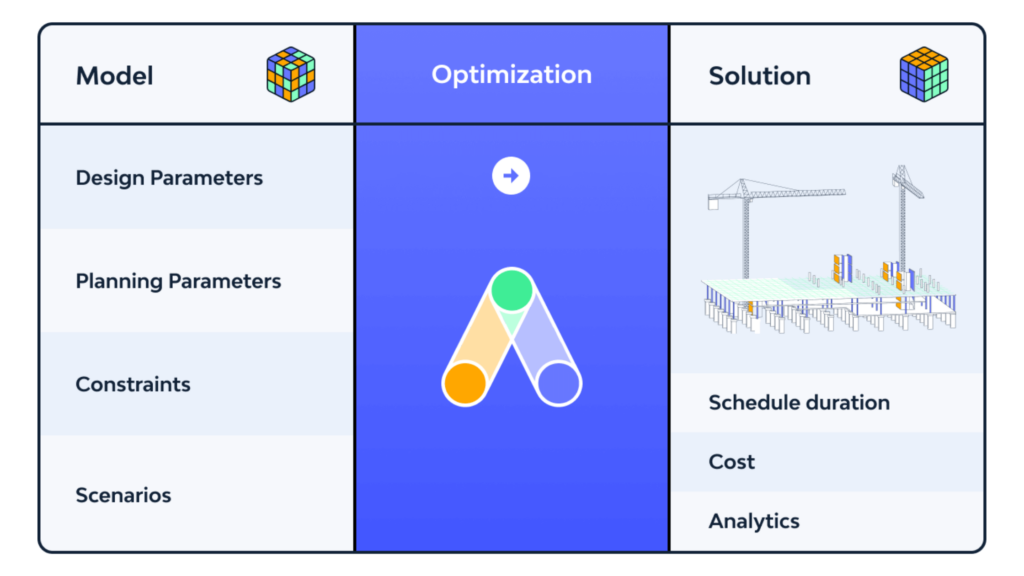

At the heart of their innovation is an AI-driven platform that not only assists in planning but transforms it. By analyzing a project’s unique parameters, ALICE’s platform generates a multitude of potential scheduling scenarios, allowing teams to explore various strategies before committing to the optimal path. This proactive approach enables contractors and owners to minimize risks, reduce costs, and accelerate project timelines.

Key features of the ALICE platform

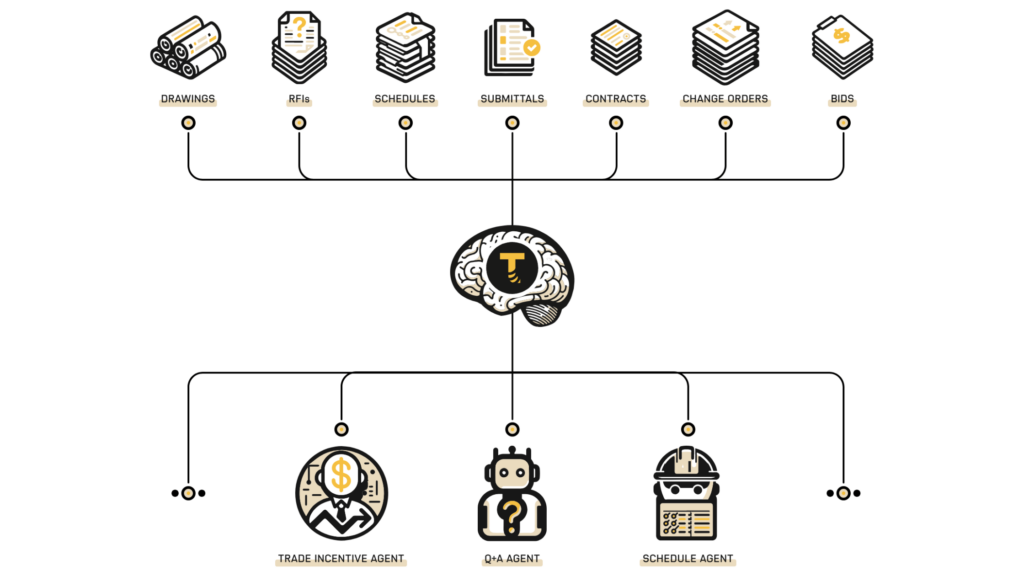

ALICE Technologies’ platform is designed to transform construction planning through several standout features:

AI-driven scenario exploration

The platform’s strength is its ability to automate scenario exploration using artificial intelligence. The system rapidly generates and evaluates numerous potential construction sequences by inputting project parameters. This allows project teams to identify the most efficient, cost-effective, and risk-mitigated paths forward. It’s like having a supercharged brainstorming session, where the AI does the heavy lifting to uncover optimal strategies that might not be immediately apparent.

Integration capabilities

Understanding the importance of seamless workflows, ALICE Core is designed to integrate effortlessly with existing scheduling tools such as Oracle Primavera P6 and Microsoft Project. Users can import their current project schedules into ALICE, allowing the platform to analyze and optimize them. Once the optimal scenarios are identified, the refined schedules can be exported back to the original tools, ensuring continuity and ease of use.

Optimization objectives

Every construction project has unique goals, whether it’s minimizing duration, reducing costs, or balancing resource utilization. ALICE’s Optimization Objectives feature empowers users to fine-tune the platform’s optimization algorithms to align with specific project priorities. By setting and prioritizing these objectives, the platform generates tailored scheduling solutions that best meet the project’s needs, providing a customized approach to construction planning.

Benefits of construction optioneering

Enhanced project efficiency

By leveraging ALICE’s AI-driven platform, project teams can explore many construction scenarios before breaking ground. This proactive approach allows for identifying the most efficient sequences and resource allocations, leading to streamlined project execution and timely delivery.

Risk mitigation

ALICE enables users to model constraints and conduct ‘what-if’ analyses, providing insights into potential challenges and their impacts. This foresight allows teams to proactively address issues, adjust plans accordingly, and reduce the likelihood of unforeseen complications during construction.

Cost savings

Implementing ALICE’s construction optioneering platform has demonstrated tangible financial benefits. On average, users have reduced project duration by 17% and labor costs by 14%. These savings contribute to more competitive bids and improved profit margins.

Case studies and real-world applications

Align JV’s Use of ALICE on the HS2 Project

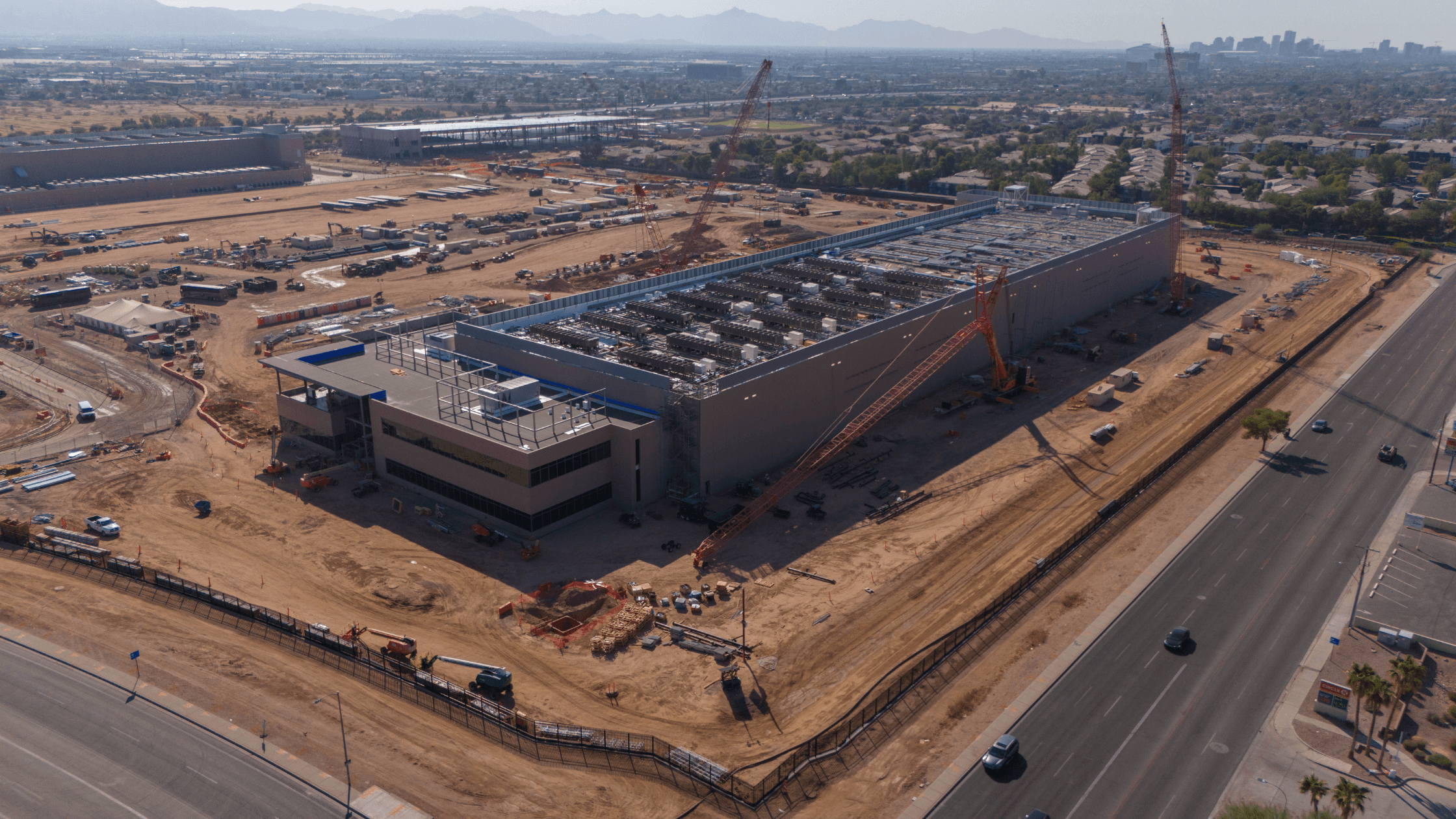

The Align joint venture (Align JV), a collaboration between Bouygues Travaux Publics, Sir Robert McAlpine, and VolkerFitzpatrick, is spearheading a significant segment of the UK’s High Speed 2 (HS2) railway project. One of their key responsibilities is constructing the Colne Valley Viaduct, a 3.4 km bridge that will be the longest railway viaduct in the UK once completed. Given the complexity and scale of the project, Align JV turned to ALICE Technologies to optimize scheduling and resource allocation.

The team used ALICE’s AI-driven construction optioneering platform to generate millions of potential sequence options and ran “what-if” analyses to determine the most efficient construction methods. This data-driven approach helped Align JV make better-informed decisions, significantly saving time and cost. Encouraged by the success of the viaduct planning, Align JV expanded its use of ALICE Technologies across additional aspects of the HS2 project, further enhancing efficiency and reducing environmental impact.

Zachry Construction + ALICE

With ALICE Technologies’ AI-powered platform, Zachry Construction Corporation, a major player in heavy civil construction, is taking its project planning to the next level. Traditional scheduling methods often rely on manual adjustments that can be slow and rigid. With generative scheduling, Zachry’s teams can explore multiple project scenarios in minutes, testing different strategies and identifying the most efficient path forward—all before breaking ground.

By automating time-intensive processes, ALICE frees project teams to focus on high-value tasks like strategic planning and risk mitigation. It also optimizes resource allocation, ensuring labor, materials, and equipment are deployed where needed most—critical for keeping heavy civil projects on track and within budget.

“With ALICE, we’re taking our capabilities to an entirely new level,” said Ranjeet Gadhoke, Vice President of Project Controls at Zachry. “By using AI-powered generative scheduling, we can evaluate risks and opportunities across our projects in a fraction of the time it previously took, allowing us to deliver better outcomes for our clients.”

Other notable projects

ALICE Technologies has played a transformative role in optimizing large-scale construction projects worldwide. In Asia, a leading Japanese contractor leveraged ALICE for an airport expansion project, where efficient crane placement and sequencing were crucial. By exploring various planning scenarios, the contractor cut the project timeline by 10.2%, significantly reducing costs while maintaining construction quality.

Meanwhile, in Norway, AF Gruppen, one of the country’s largest construction firms, used ALICE to refine scheduling and crew configurations for a mid-rise residential development. By identifying the most efficient resource allocation strategy, AF Gruppen reduced project duration by 18% and overall costs by 30%.

In the United States, a general contractor working on an eight-mile interstate highway widening project faced significant delays. With ALICE’s platform, the contractor could resequence the project plan, recover lost time, and complete the project ahead of schedule. “We were able to get many variable scenarios that we could analyze,” the contractor said. “In the end, it became a much more efficient tool for us to use than traditional solutions.” This early completion translated to over $25 million in savings from early completion bonuses and cost reductions.

The future of construction optioneering

The construction industry is at a turning point as AI-driven technologies become a core part of project planning and execution. With 94% of businesses planning to adopt AI and machine learning, the shift toward digital transformation is happening fast—and for a good reason.

AI-powered construction optioneering is changing project planning. Instead of relying on rigid schedules, teams can analyze massive datasets to predict project outcomes, optimize resource allocation, and spot potential risks before they become costly problems. This proactive approach helps crews make smarter decisions, leading to faster, more efficient, and cost-effective builds.

Beyond smarter planning, AI also automates complex scheduling, allowing project managers to test multiple scenarios in seconds and choose the best strategy to keep projects on track. By adapting to real-world challenges in real-time, AI is helping construction teams reduce delays, cut costs, and build confidently.

Bottom line

By replacing rigid, single-scenario scheduling with AI-driven scenario exploration, ALICE Technologies is helping contractors, developers, and project managers reduce costs, mitigate risks, and accelerate project timelines, proving that smarter planning leads to smarter building. As AI continues to evolve, the potential for optioneering will only grow, making it an indispensable tool for industry professionals who want to stay ahead of the curve.

Want to stay ahead of the latest trends in construction technology? Subscribe to our newsletter and follow us on social media for expert insights, industry updates, and innovative solutions to take your projects to the next level.