BC contractors face 72% skilled labor shortage amid rising project delays

February 14, 2025

Nearly 65% of BC contractors spend more time and resources on recruitment as labor shortages slow construction and increase costs.

Breaking barriers: Checkr’s apprenticeship program opens doors in construction

January 10, 2025

Checkr’s apprenticeship program connects workers with criminal records to opportunities in construction to address labor shortages.

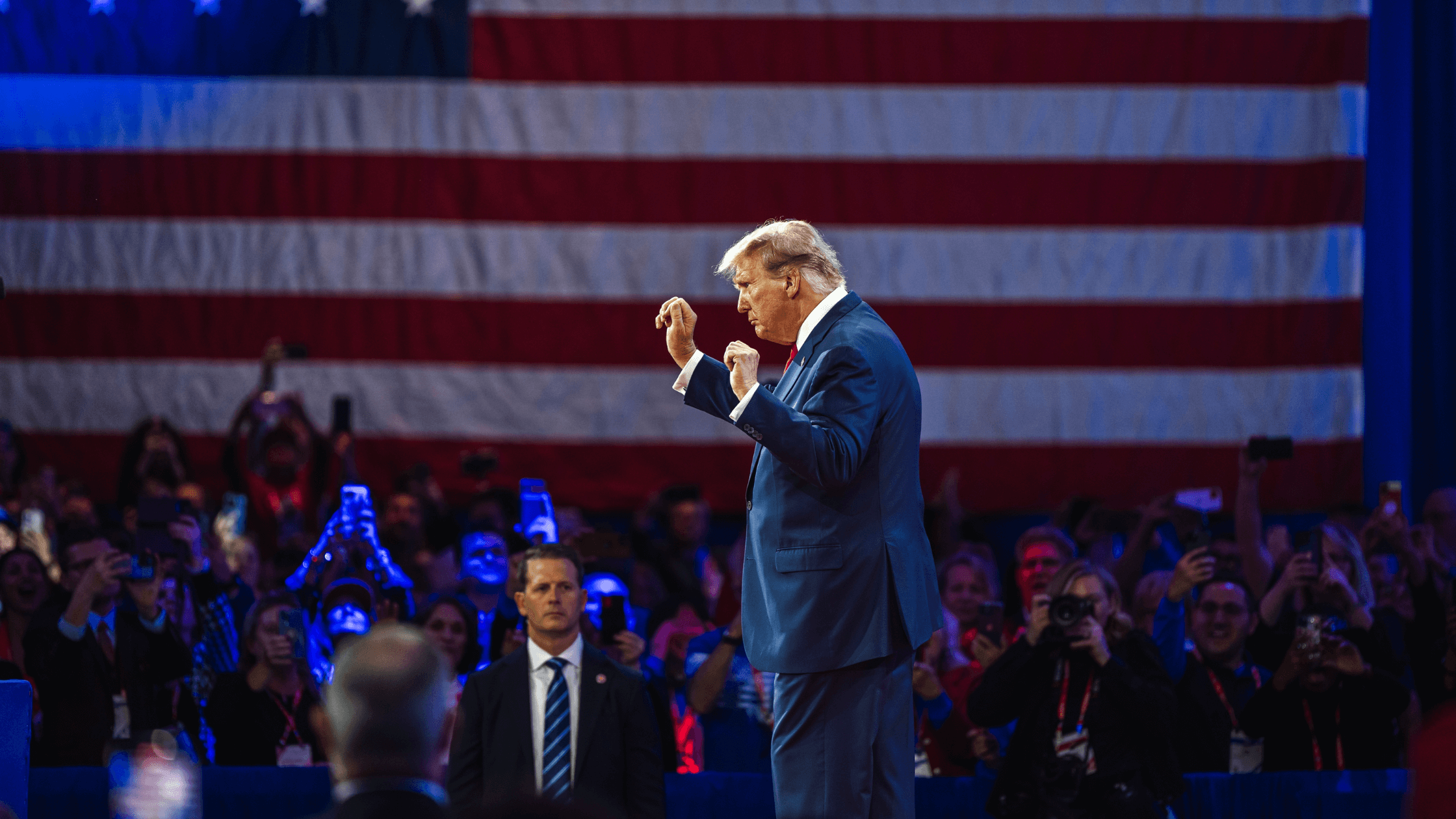

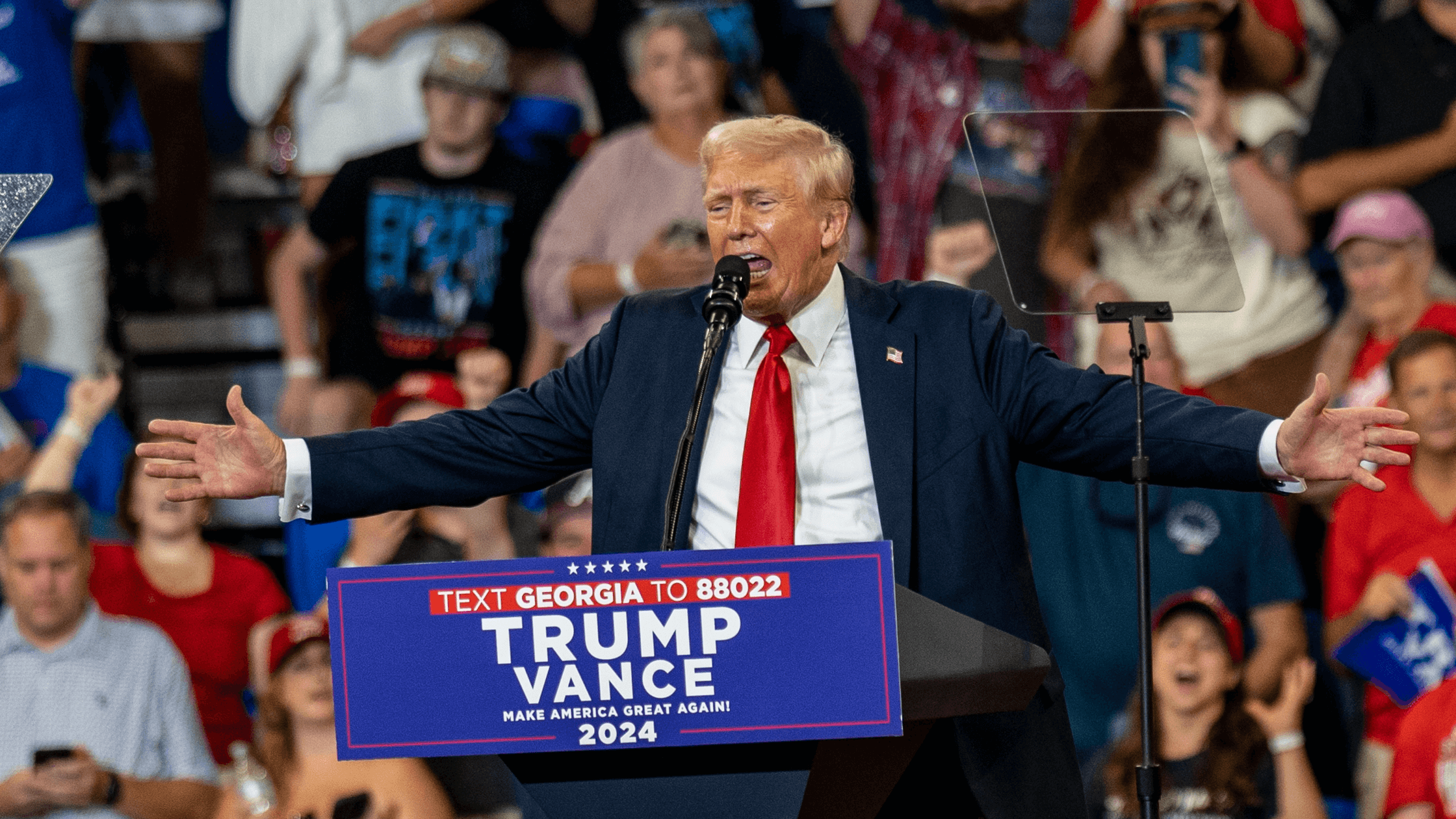

Trump’s deportation plans could undermine U.S. construction

December 30, 2024

Trump’s proposed deportation of undocumented workers threatens to disrupt the U.S. construction industry with labor cuts.