The new president’s recent announcement of a $500 billion investment in AI infrastructure is set to significantly affect multiple industries, particularly construction. The demand for new data centers, advanced building materials, and cutting-edge construction technology will grow as AI infrastructure expands. This initiative will create job opportunities, increase project demand, and accelerate innovation in construction-related fields.

A construction boom: Building the backbone of AI

The demand for data centers will skyrocket

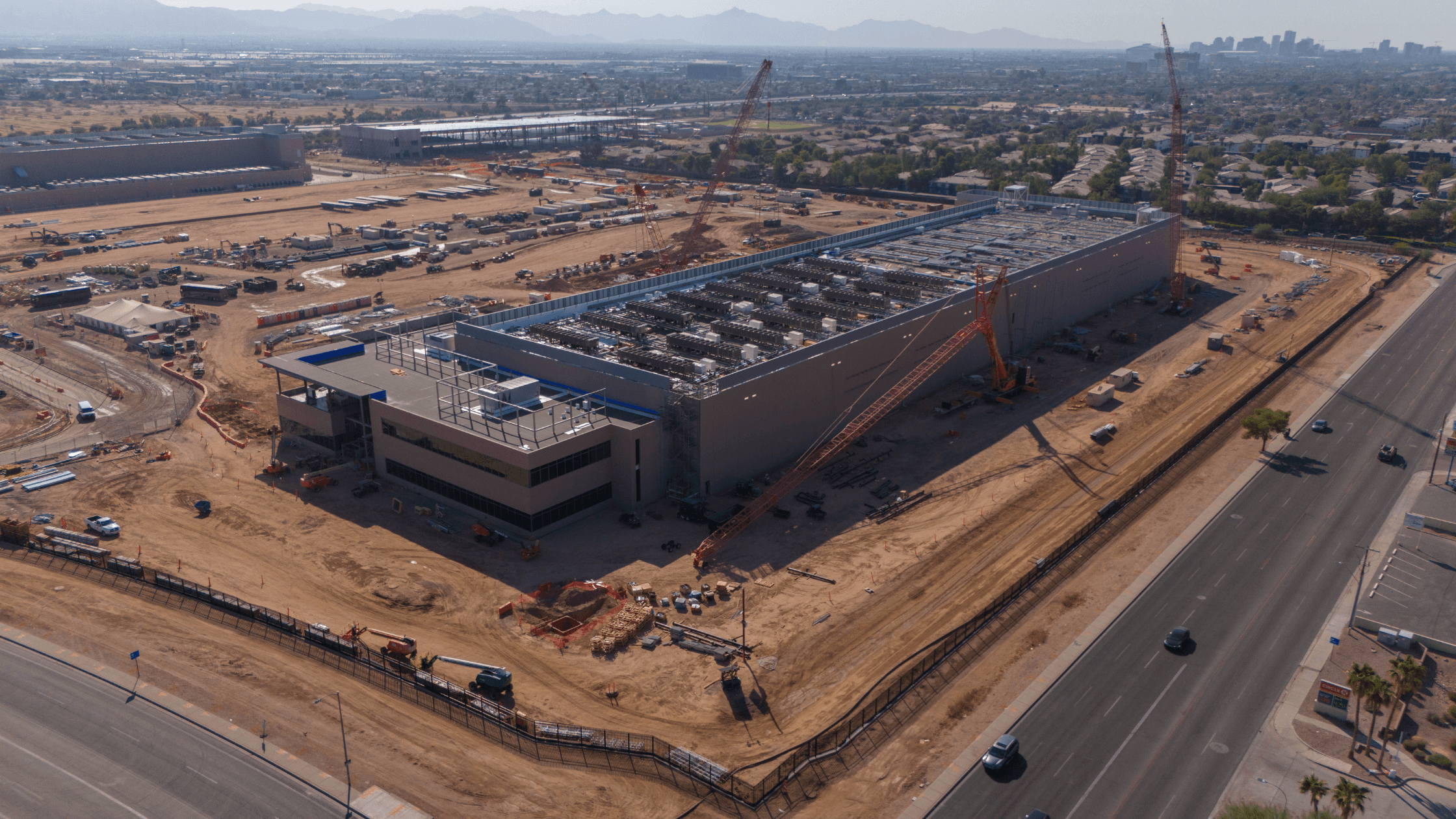

AI models require immense computing power to function, and that power comes from specialized data centers. These buildings house high-performance servers, extensive cooling systems, and complex electrical grids to support AI operations. The need for more secure, energy-efficient, and scalable facilities will drive massive construction efforts nationwide.

Major tech companies like Google, Microsoft, and Amazon have already invested heavily in AI and cloud computing. With additional federal backing, hundreds of new data centers could be built in urban and rural areas across the U.S. This would directly impact contractors, architects, and construction workers, as they would be responsible for designing and building these high-tech facilities.

Specialized skills will be in high demand

Constructing AI-focused data centers requires a highly skilled workforce. These projects demand expertise in:

- Electrical engineering – data centers require specialized power distribution to support AI servers

- HVAC and cooling systems – AI generates extreme heat, requiring advanced cooling solutions

- Structural engineering – these buildings must be sturdy, earthquake-resistant, and expandable

- Cybersecurity construction – with AI systems handling sensitive data, facilities need secure physical structures to prevent breaches

With the increased demand for these skill sets, companies may need to invest in training programs to ensure workers are prepared for these high-tech projects.

How AI will change construction itself

As AI becomes more integrated into the construction industry, its impact on efficiency, safety, and cost management will be significant. From improving blueprint analysis to optimizing supply chains and enhancing worksite safety, AI-driven solutions are changing how projects are planned and executed. These advancements lead to faster completion times, fewer mistakes, and better resource allocation, helping construction firms stay competitive in an AI-driven economy.

AI-powered blueprint analysis

Traditional blueprint analysis is time-consuming and prone to human error. AI can analyze thousands of blueprints in minutes, identifying potential design flaws, structural weaknesses, or inefficiencies before construction even begins. This early detection helps architects and engineers refine their plans, reducing costly mid-project changes.

AI also assists in optimizing space utilization and material usage, leading to more sustainable and cost-effective designs. By catching errors at the planning stage, AI-powered blueprint analysis streamlines the construction process and minimizes delays.

Smarter supply chain logistics

AI is revolutionizing supply chain management by predicting material shortages, tracking price fluctuations, and optimizing delivery schedules. Construction projects rely on precise timing, and any disruption in material availability can cause costly delays.

AI-driven logistics platforms use real-time data to anticipate supply chain issues and suggest alternative suppliers or materials before problems arise. This predictive approach helps reduce waste, lower costs, and ensure projects stay on schedule. As AI continues to refine its forecasting abilities, construction companies will be able to maintain more efficient and reliable operations.

Enhanced worksite safety

Construction sites are inherently hazardous, but AI is making them safer. Wearable technology equipped with AI-driven sensors can monitor workers’ movements, detect fatigue, and alert supervisors to potential dangers. AI-powered cameras and drones can scan worksites in real time for safety violations, such as missing protective gear or unstable structures.

Additionally, predictive analytics can identify high-risk areas based on historical accident data, allowing companies to implement preventative measures before incidents occur. By integrating AI into safety protocols, construction firms can significantly reduce workplace injuries and improve overall job site security.

Robotics and 3D printing will become more common

As AI advances, robotics and automated systems will become more prevalent in construction. AI-powered robotic arms are already being used to lay bricks, weld steel, and perform repetitive tasks with greater precision than human laborers.

Additionally, 3D printing in construction is expected to grow. With AI-driven design, companies can print entire structures from sustainable materials, reducing costs and construction time. These technologies will be crucial in building the next generation of AI data centers quickly and efficiently.

The impact on costs, sustainability, and labor

Higher demand may drive up construction costs

With an increased demand for AI infrastructure, the prices of materials such as steel, concrete, and high-performance insulation may surge. As demand outpaces supply, the cost of skilled labor could also increase.

However, the widespread adoption of AI-powered project management could offset some of these costs by making construction more efficient, reducing waste, and optimizing supply chains.

Energy-efficient and sustainable construction will be a priority

AI infrastructure is energy-intensive, requiring massive cooling and power systems. This will push sustainable construction methods into the spotlight. Expect to see:

- Advanced insulation and energy-efficient building materials

- On-site renewable energy sources, such as solar and wind power

- Smart grid integration to optimize electricity use

As the industry shifts toward green solutions, construction companies will need to adapt to new energy standards and incorporate sustainability into their building practices.

A surge in construction jobs and workforce development

With billions being poured into AI infrastructure, thousands of new jobs will be created in construction. Positions in civil engineering, electrical work, and mechanical systems installation will see significant growth.

However, new skill sets will be required. Companies will need to invest in worker training and apprenticeship programs to keep up with the industry’s demands. Expect an increase in construction tech courses and certifications tailored to AI-driven projects.

Professional construction services vs. AI-driven software

With AI playing a larger role in construction, firms will have to choose whether to hire professional takeoff and estimating services or adopt AI-driven software solutions. AI-powered tools can generate precise cost estimates, automate material orders, and predict project timelines. While these tools improve efficiency, they require training and initial investment.

On the other hand, professional services provide human oversight and expertise that AI may not yet match. The best approach for many companies will likely be a combination of both—leveraging AI to handle repetitive tasks while relying on experienced professionals for critical decision-making.

Bottom line

The president’s $500 billion AI infrastructure investment will bring unprecedented growth to the construction industry. From building high-tech data centers to adopting AI-powered project management and robotics, construction will see massive technological advancements in the coming years.

As demand for new projects, skilled labor, and sustainable building methods increases, construction professionals must adapt and innovate to stay ahead. Whether you’re a contractor, engineer, or project manager, now is the time to prepare for the AI-driven future of construction.

Want to stay updated on how AI is shaping construction? Subscribe to Under the Hard Hat’s weekly newsletter and follow us on LinkedIn for exclusive industry news, insights, and expert analysis.