When people think about innovation in construction, they rarely picture rebar prefabrication. That’s where Toggle Robotics stands out. Based in New York, this construction-tech startup is transforming one of the industry’s most repetitive and labor-intensive tasks into a faster, safer, and more precise process. Their system combines robotics, AI, and software tools to enhance productivity on major infrastructure and high-rise projects which has led to yearly increases in profit growth.

Rebar assembly meets automation with Toggle Robotics

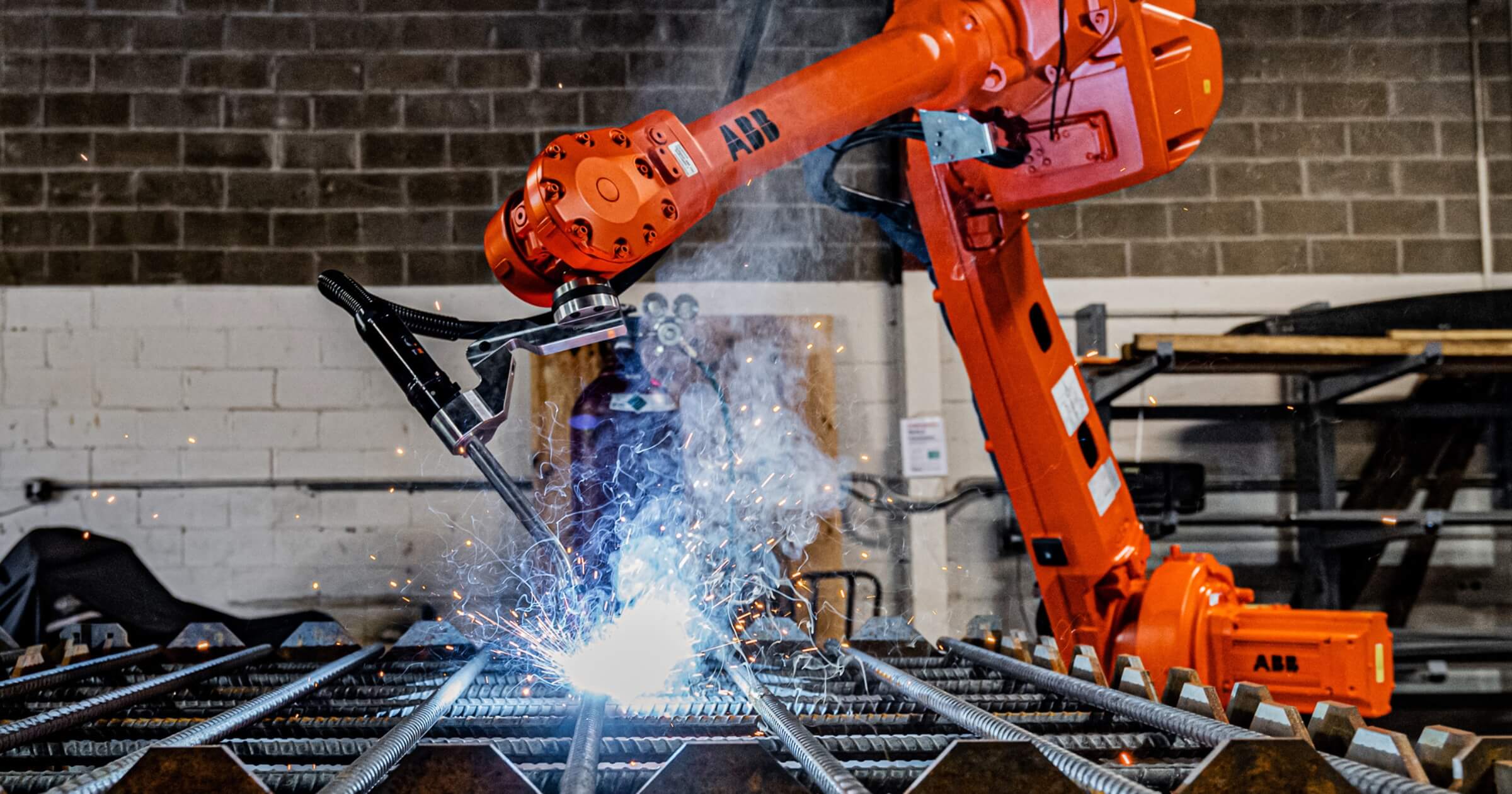

Traditionally, assembling rebar has been slow, physically taxing, and difficult to scale. Toggle Robotics approached this issue by building a digital construction toolset that includes a proprietary software platform, automated fabrication systems, and robotic arms that tie and assemble rebar at scale.

Their robots are used in off-site facilities where rebar assemblies are pre-made and then shipped to job sites. This modular approach keeps jobsite activity lean while allowing more complex assemblies to be completed in parallel. Toggle claims it can deliver assemblies up to five times faster than conventional labor-based methods. Thanks to this speed of production, it has been used on several projects helping it secure 3.2 million dollars in revenue in 2024.

On the backend, Toggle Robotics digital software is where much of the AI technology is implemented. It helps plan, track, and optimize production. Operators input project details and receive fabrication-ready instructions for the robot fleet. It’s a blend of physical automation and intelligent software that allows tradespeople to shift from manual tying to machine supervision and digital production roles.

Their work is being used in major infrastructure projects, particularly in transportation, where rebar demands are high and timelines are tight. One New York transit expansion saw Toggle-produced cages arrive days ahead of schedule, reducing crane time and labor bottlenecks.

Photo courtesy of https://toggle.build/

Toggle’s approach also opens doors for better safety.

Because much of the bending, cutting, and tying is handled off-site, tradespeople are protected from repetitive strain injuries and hazardous job site conditions. For a labor pool that’s aging and hard to replace, automating heavy, low-skill work is a workforce strategy that could help reduce the current labor gap plaguing the industry.

While many people fear AI will replace hard working jobs, Toggle Robotics has demonstrated that construction robots don’t need to replace workers to make a difference. Instead, they’re filling the gaps, shifting the workload, and creating new technical roles that appeal to a younger workforce.

To keep up with how tools like Toggle Robotics are changing the way we build, subscribe to the Under the Hard Hat newsletter at underthehardhat.org/join-us. We cover the construction tools and companies shaping the future of the trades.