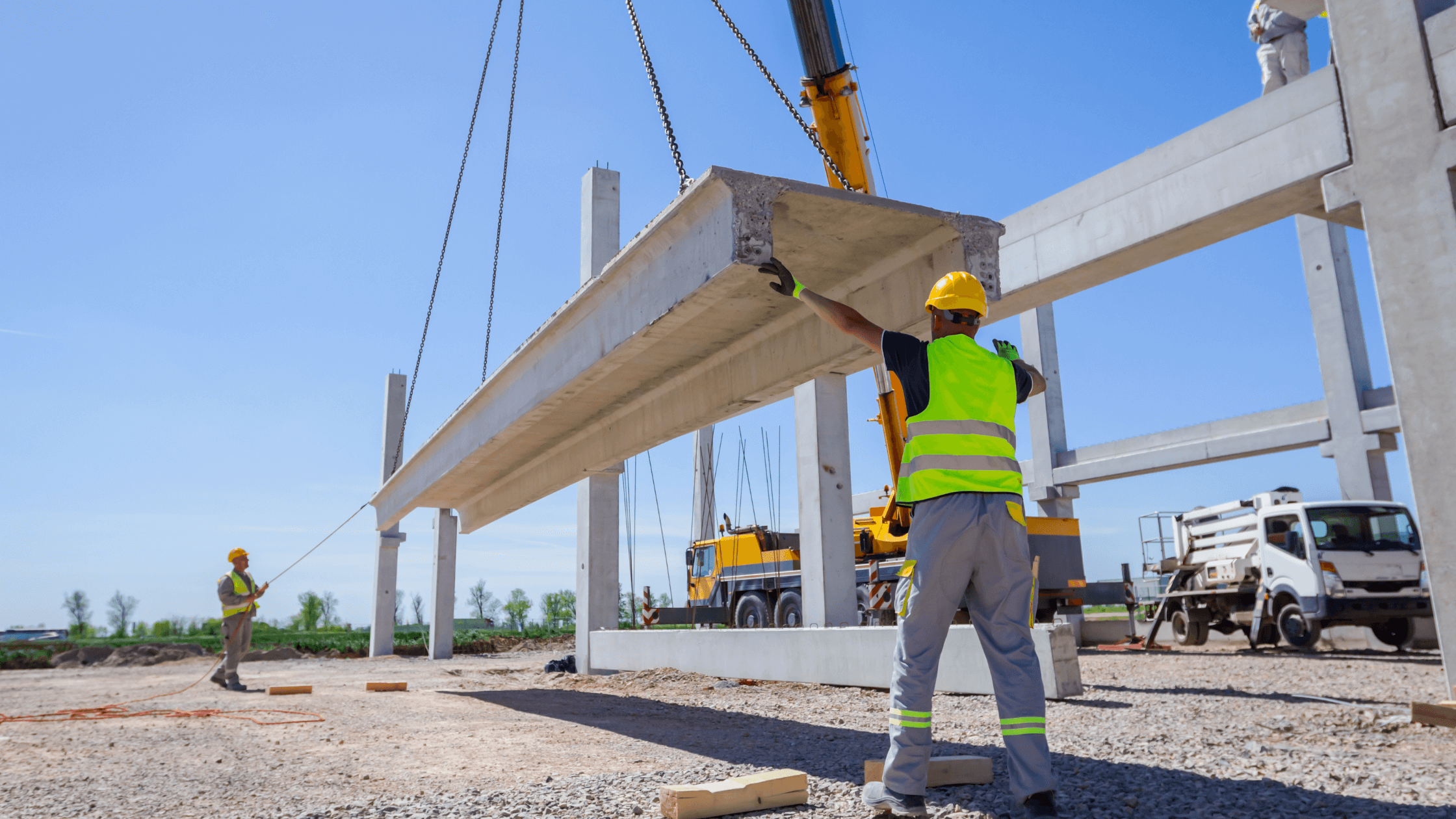

In physically demanding jobs like construction, workers constantly perform tasks that strain their bodies. Ergonomics—designing tools and tasks to fit the worker—is important in keeping construction professionals safe and efficient. By focusing on simple strategies like balancing the tool belt and labeling loads, workers can reduce their risk of injury, improve productivity, and enjoy longer, healthier careers.

Quick look

- Ergonomics helps reduce the risk of injury and improves productivity for workers in physically demanding jobs.

- Musculoskeletal disorders (MSDs) like nerve compression and herniated discs are common in construction, affecting up to 96% of workers annually.

- Poor ergonomic practices can lead to productivity issues and increased costs due to injury.

- Following ergonomic tips, like choosing the right tools and lifting properly, helps construction workers stay safe and efficient.

What is ergonomics?

Ergonomics is the science of designing jobs, equipment, and workspaces to fit the needs of workers, especially in physically demanding jobs. By adapting tools and tasks to the human body, ergonomics helps reduce strain, prevent injuries, and improve productivity. For example, using ergonomic tools with anti-vibration handles can reduce strain on hands and wrists to reduce the risk of carpal tunnel syndrome, while adjustable scaffolding heights help prevent back and knee injuries from repetitive bending or reaching. These adaptations make a huge difference in long-term worker’s health and longevity.

Why ergonomics matters in physically demanding jobs

In physically demanding jobs, ergonomics plays an even bigger role for several reasons:

- Prevent MSDs and injury: Musculoskeletal disorders are common among construction workers due to repetitive tasks, heavy lifting, and awkward postures. Good ergonomic practices help reduce the risk of these injuries.

- Avoid changes in productivity: Productivity is significantly affected when workers are injured. Ergonomics can help maintain a steady workflow by minimizing injury-related disruptions.

- Reduce injury-related expenses: Injuries lead to medical expenses and lost workdays, costing employers and employees money.

- Increase efficiency: Ergonomics helps workers complete tasks with less effort, making them more efficient and reducing fatigue.

- Boost morale and job satisfaction: Workers who feel safe and comfortable on the job are more likely to stay satisfied and engaged.

Musculoskeletal disorders in construction

MSDs are a major concern in the construction industry. These injuries, which primarily affect muscles, tendons, and nerves, are among the most common health issues construction workers face. The physical nature of construction work—repetitive motions, lifting heavy materials, and working in awkward positions—makes workers vulnerable to MSDs.

According to industry data, construction workers have some of the highest rates of MSDs of any industry. Studies have shown that the prevalence of work-related MSDs in construction can range from 25% to as high as 96% in some specialties, showing a widespread issue across the industry. This high rate of MSDs not only affects workers’ health but also contributes to increased medical costs, lost productivity, and even permanent disability in severe cases.

Phases of MSDs

MSDs generally progress through four phases, each presenting different levels of pain and physical impairment:

- Acute: This initial phase includes minor discomfort or pain during or after work activities but typically resolves with rest.

- Mild: Pain becomes more frequent and may start affecting work performance. At this stage, minor adjustments in work practices can help manage symptoms.

- Moderate: Persistent pain that typically requires medical intervention. Workers in the moderate phase struggle to complete tasks; ignoring symptoms at this point can lead to more severe issues.

- Severe: Severe MSDs involve chronic pain that significantly limits a worker’s ability to perform daily activities. In extreme cases, it leads to permanent disability or the need to leave the workforce.

Risk factors

Several factors contribute to the high risk of MSDs in construction:

- Repetitive motions: Repeating the same movements, such as hammering or lifting, can strain muscles and joints, leading to overuse injuries.

- High-force tasks: Activities requiring significant physical effort, like lifting heavy materials or operating power tools, stress the musculoskeletal system.

- Awkward positions: Construction often requires workers to work in cramped or unusual positions, leading to strain on muscles and joints.

- Contact stress: Using tools that press against certain areas of the body can cause localized pressure injuries.

- Vibration exposure: Operating vibrating tools like jackhammers or drills can lead to nerve damage and circulatory problems in the hands and arms.

The consequences of MSDs go beyond physical pain. They lead to high absenteeism rates, reduced productivity, and substantial medical expenses. Implementing ergonomic solutions and adopting safe work practices are crucial steps to minimize these risks and create a safer work environment for construction workers.

Ergonomic safety tips for skilled trades workers

For skilled trades workers, practicing good ergonomics can make a big difference in preventing injuries and improving work performance. Here are some practical ergonomic tips tailored to the demands of construction work:

1. Choose ergonomically correct tools

Using ergonomically designed tools can reduce strain on muscles and joints. Look for tools that fit comfortably in your hand, have cushioned grips, and are lightweight. Ergonomically designed tools minimize the force needed for tasks, helping to prevent repetitive strain injuries and reduce fatigue over a long workday.

2. Label all loads with the correct weight

Clear weight labeling on loads helps prevent workers from accidentally attempting to lift items that are too heavy. Knowing the weight beforehand allows for proper preparation or for workers to seek assistance when needed, which minimizes the risk of overexertion injuries.

3. Design storage for easy access at waist height

Store frequently used tools and materials at waist level to reduce the need for excessive bending, reaching, or stretching. This approach keeps materials within easy reach and minimizes the physical strain of awkward movements, helping workers maintain a safer and more ergonomic work posture.

4. Avoid prolonged bending

Constantly bending over or kneeling can place extra stress on the back, knees, and hips. Whenever possible, use adjustable work platforms or knee pads to work at a comfortable height. Consider alternating tasks that require bending with tasks that allow a more upright position, helping to maintain a neutral spine and reducing the risk of back strain.

5. Balance your tool belt

An imbalanced tool belt places uneven pressure on the hips and lower back, leading to muscle strain over time. Distribute the weight of tools evenly on both sides of the body, and only carry what’s necessary for the task at hand. This simple adjustment helps reduce unnecessary strain and keeps your body balanced while moving around the job site.

6. Lift with your legs and hips

Lifting heavy materials is a common task in construction, but improper lifting techniques can lead to severe injuries. Instead of bending using the back, bend your knees and hips to lower your body to the object. Keep the object close to your body as you lift and engage the core rather than relying purely on your hip and leg muscles. This method distributes the weight more evenly and reduces the risk of injury.

7. Recruit the help of others for heavy loads

For objects over 50 pounds, avoid lifting alone. Team lifting or using mechanical aids like dollies or hoists can prevent overexertion injuries. Asking for assistance when handling heavy materials is essential for long-term health and safety on the job.

8. Avoid twisting the spine while lifting or installing

Twisting your spine under load is a common mistake that increases the risk of serious back injuries. Keep your feet, hips, and shoulders aligned when lifting or installing. If you need to turn, move your entire body toward the task instead of twisting your torso. This technique reduces strain on the spine and prevents disc injuries.

Bottom line

Ergonomics is an essential part of health and safety for construction and trade jobs to reduce injuries, improve efficiency, and maintain long-term health. By adopting simple ergonomic practices, construction workers can protect themselves from common work-related injuries that impact their quality of life.

Want more tips on staying safe and productive in your work? Subscribe to our newsletter for expert advice on workplace safety, health, and productivity tailored to skilled trades professionals.

1 comment