Robotics is rapidly transforming the construction industry, helping companies overcome labor shortages and enhance safety on job sites. Innovators like Built Robotics, Boston Dynamics, and Canvas are automating tasks such as earthmoving, material handling, and even drywall installation.

Robotics is making waves in just about every industry you can think of, and construction is no exception. As the need for quicker, safer, and more efficient building processes ramps up, some of the top robotics companies are shaking up the construction world, making everything smarter, safer, and a whole lot faster. From autonomous machines to AI-powered site inspections, construction is starting to lean on robotics in a big way. And it’s not just about fancy tech—robots are becoming essential to the future of building.

The role of robotics in construction

With robots improving efficiency, precision, and productivity, the future of construction is being built faster and safer than ever before. Robotics is tackling some of the construction industry’s biggest challenges. For example, one of the most pressing issues is labor shortages. With fewer workers available, robots fill the gaps by taking on tasks like bricklaying, earthmoving, and even drywall installation, ensuring projects keep moving forward.

Beyond filling in for labor, robotics also boosts productivity and precision. Robots can work continuously without breaks, meaning tasks that used to take days or weeks can now be completed in a fraction of the time. Companies like Construction Robotics are automating bricklaying, while Canvas focuses on drywall installation, both of which help crews work faster and with greater accuracy.

Safety is another huge benefit. By handling dangerous jobs like demolition, robots reduce worker risks on-site. With robots taking on the heavy lifting and hazardous tasks, human workers can focus on less risky, more skilled work, improving safety and overall job satisfaction.

These advances in robotics are not just about speed or efficiency—they’re about creating a smarter, safer, and more sustainable construction industry.

10 Companies revolutionizing the industry with robotics

Built Robotics

Built Robotics is at the forefront of autonomous construction machinery. Their key product, the Autonomous Track Loader (ATL), focuses on earthmoving tasks, reducing the need for human intervention and allowing work to continue seamlessly across job sites.

Construction Robotics

Construction Robotics is known for its innovative SAM (Semi-Automated Mason) and MULE (Material Unit Lift Enhancer) systems, which are transforming bricklaying and materials handline. These robots help speed up traditionally labor-intensive tasks, reducing physical strain on workers.

Hadrian X

Hadrian X is a game-changer in bricklaying. It uses 3D-printed construction technology to build faster and more precisely than ever. This technology significantly reduces labor costs and timelines for projects that rely on brick structures.

Canvas

Canvas is revolutionizing drywall installation with its robotic systems designed to smooth and tape walls, cutting down on time and increasing accuracy. This automation helps crews work faster while maintaining high-quality standards on-site.

Boston Dynamics

Famous for its robots like Spot and Stretch, Boston Dynamics has found valuable applications in construction. Their robots can perform safety inspections, inventory management, and heavy material handling, improving site productivity and safety.

Kewazo

Kewazo specializes in smart robotic scaffolding systems that improve labor efficiency and reduce construction costs. Their intelligent scaffolding robots speed up installation and enhance site safety by reducing the need for risky manual labor.

Dusty Robotics

Dusty Robotics automates the layout process for construction sites, which typically requires precision and time. By automating this process, Dusty Robotics ensures projects move forward faster and with minimal errors, helping to meet tight deadlines.

Brokk

Brokk is the leader in remote-controlled demolition robots, known for their power and precision in small, tight spaces. Their machines make demolition safer by allowing operators to control the robot from a safe distance, avoiding direct exposure to hazardous environments.

Fast Brick Robotics

Fast Brick Robotics specializes in rapid and accurate bricklaying through automation. Their technology speeds up construction times and reduces labor costs, making large-scale building projects more efficient.

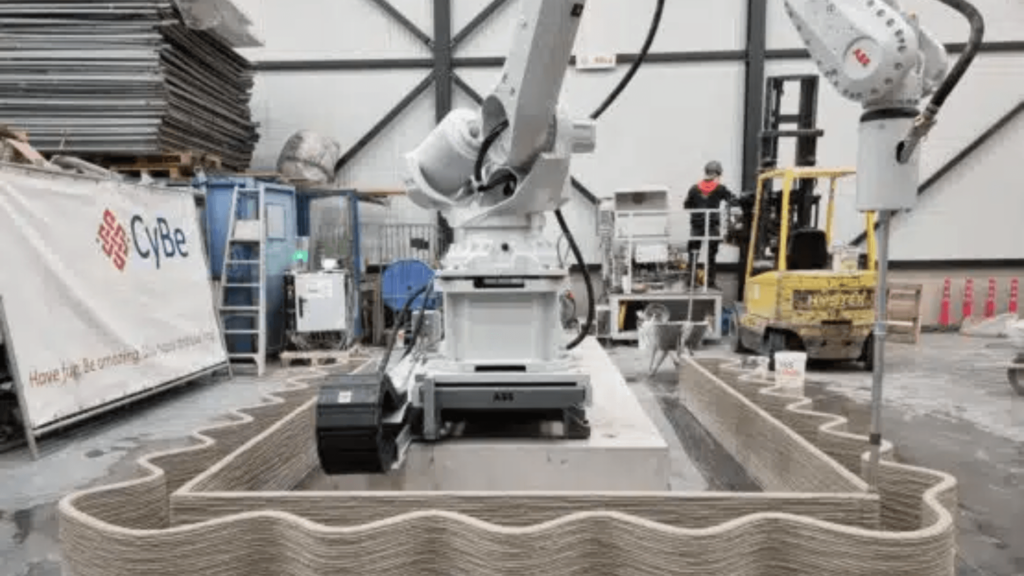

CyBe Construction

CyBe Construction is leading the way in 3D concrete printing. Their robotics systems enable fast, sustainable construction by printing concrete structures directly on-site. This cutting-edge technology helps reduce material waste and speeds up the construction process, making it a valuable asset to the industry’s future.

The future of robotics in construction

As companies continue to see the benefits—improved safety, faster project completion, and reduced labor costs—it’s clear that robots are here to stay. The future of robotics in construction is incredibly promising, with industry experts predicting a significant increase in the adoption of robotics across job sites.

One of the most exciting emerging trends is integrating artificial intelligence (AI) into construction robotics. With AI, robots will perform tasks, learn, and adapt to their environments, improving efficiency with each job. This could mean fewer human errors, faster decision-making, and greater precision in complex tasks like building layouts or site inspections.

Another trend to watch is the rise of robotic collaboration, where multiple robots work together on a construction site. Imagine a site where a demolition robot, like Brokk, clears a space while a robotic bricklayer, like Hadrian X, immediately starts building without missing a beat. These collaborations could revolutionize how we approach large-scale construction projects, making them more efficient and cost-effective.

As AI advances and robotic technology becomes more accessible, we’ll likely see even more innovative applications across the industry. The future of construction will undoubtedly involve a mix of human expertise and robotic precision, working together to build smarter, faster, and safer projects.

The wrap-up

Robotics are no longer a futuristic concept—they’re an essential part of today’s construction industry, helping to solve significant challenges like labor shortages, safety concerns, and the constant demand for greater efficiency. From earthmoving to bricklaying and demolition to drywall installation, these innovative companies are proving that robots can tackle a wide range of tasks, often faster and with more precision than human crews alone.

The bottom line? Robotics aren’t just a trend—they’re the future of construction. And as these technologies continue to develop, the industry will only benefit from smarter, safer, and faster builds.

1 comment