Some occupations require employees to work with or handle toxic substances and chemicals that can have adverse health consequences. OSHA requires employers to identify and evaluate the respiratory hazard(s) in their workplaces and ensure exposure does not exceed recommended exposure limits. Employers can keep their workers safe through engineering and work practice controls and by providing proper PPE.

Quick look

- Dust, solvents, mold, and man-made mineral fibers are some of construction sites’ most common toxic substances.

- Wood dust, silica, and lower-toxicity dust are most common on job sites, with silica dust being the most hazardous to health.

- It is essential to take extra precautions when working around hazardous substances, such as wearing proper PPE and reducing exposure through skin or inhalation.

- All employees have the right to know about hazardous materials on job sites, and it’s the employer’s responsibility to reduce exposure risk as much as possible.

Common causes of toxin or chemical exposure

Identifying the source is the first step in reducing worker exposure to chemicals and toxic substances on the job site.

Here are some of the most common hazardous substances on construction sites.

Dust

Dust is one of the most common substances found on construction sites. Although it may not seem like the biggest hazard, when inhaled repeatedly, certain types of dust can lead to serious health consequences, especially ones affecting the lungs and respiratory system.

Dust on construction sites usually falls into one of three categories:

1. Wood dust: Comes from handling wood through sanding and cutting. According to the International Agency for Research on Cancer (IARC), repeated inhalation of wood dust can cause cancer of the nasal cavity, paranasal sinuses, and nasopharynx. It’s also associated with toxic effects, irritation of the eyes, nose, and throat, dermatitis, and respiratory system effects that include decreased lung capacity and allergic reactions.

2. Silica dust: Silica dust is the most dangerous type of dust on construction sites, caused by working with materials containing silica (sandstone, concrete, etc.). Tiny airborne particles are inhaled and settle into the lungs, causing long-term scarring and silicosis, a fatal lung disease.

3. Lower toxicity dust: Lower toxicity dust comes from working with materials like drywall, marble, and other substances. Although not as hazardous, long-term exposure can still cause lung damage.

How to reduce exposure: The easiest way to minimize dust exposure is to utilize a system that suppresses dust. Vacuum systems are easy to install and reduce the amount of airborne dust. Using appropriate PPE can also minimize inhalation.

Solvents

Solvents, commonly found in paints, adhesives, and cleaning fluids, are another common substance on construction sites. Solvents can be dangerous for the lungs and skin and can adversely affect nerve and brain function. Long-term exposure to solvents can cause arrhythmias (irregular heartbeats), cancer, blindness, kidney/liver damage, and even death.

Common symptoms of solvent exposure include:

- Stomach pain

- Headache

- Dizziness

- Nausea

- Loss of coordination

- Cracked/bleeding skin

How to reduce exposure: Exercise extra caution when working with solvents. Keep them out of contact with skin and wash hands and body thoroughly after use. Avoid working in a confined space with minimal ventilation and air circulation.

Mold

Mold is another common hazard found on construction sites that can lead to permanent health issues with repeated and prolonged exposure. Mold arises in damp conditions and becomes problematic when moisture becomes trapped in buildings. Asthma and allergy symptoms are mold exposure’s most common side effects, but other respiratory problems can also arise. Long-term exposure can lead to chronic sinusitis, increased risk of upper and lower respiratory symptoms, fatigue, and organ failure.

People with pre-existing respiratory conditions should take extra precautions when working around mold.

How to reduce exposure: The easiest way to reduce exposure to mold in the workplace is to use personal protective equipment. When working in areas with mold, consider using respirators, gloves, and goggles to avoid contact with lungs, skin, and eyes.

Man-made mineral fibers

Man-made mineral fibers are also a common find on construction sites. They’re typically made from glass ceramic, rockwool, and slagwool and are generally used for temperature and sound insulation. When these materials are installed or removed, they release tiny fibers that can become lodged in the lungs, leading to irritation and damage to the lungs, eyes, and skin.

Some types of man-made mineral fibers, specifically those classed as refractory ceramic fibers, may require specialized PPE when working with them.

How to reduce exposure: Use caution and be smart. Always wear the appropriate PPE when working with hazardous materials, which adequately protects you against contact with tiny fibers.

How to reduce exposure to workplace chemicals and toxins

OSHA guidelines recommend specific actions based on an employee’s level of exposure to a toxic substance or chemical hazard.

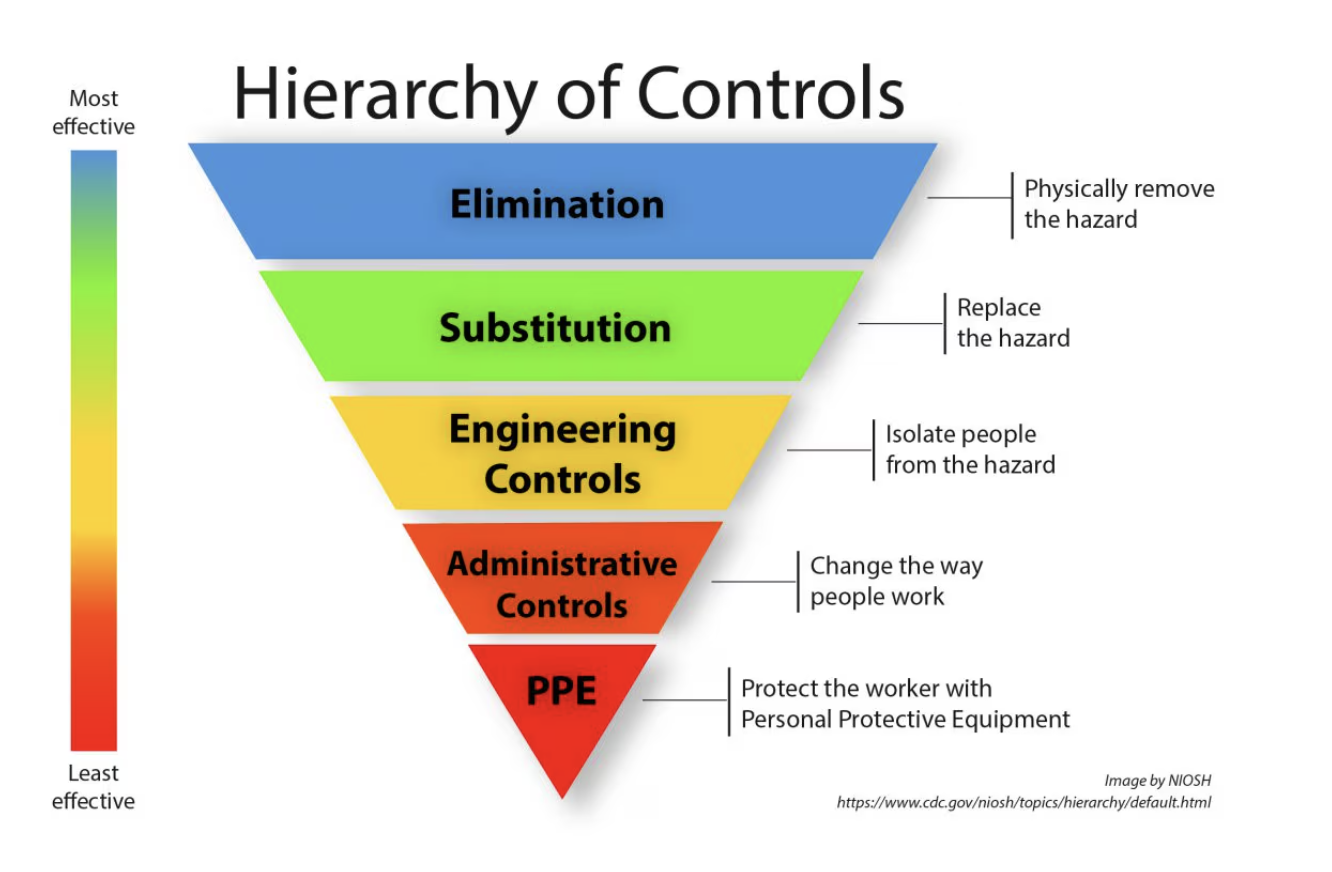

The CDC’s hierarchy of controls can be used to assess the action an employer should take to prevent or limit exposure to hazardous substances. The top of the pyramid signifies the ideal position (best-case scenario), while the bottom is the least ideal.

Here’s what an employer should do based on where they sit on the pyramid:

- Elimination or substitution: If the chemical or toxin isn’t necessary, it should be eliminated. If it is needed, try to substitute it with a safer substance.

- Engineering controls: Whenever possible, make the chemical safer to use. The workplace should also make changes to reduce or eliminate exposure to hazardous substances or materials.

- Administrative and work practice controls: If the substance remains unsafe after physical changes, the employer should implement specific processes or procedures that minimize worker exposure, such as retaining job assignments or altering work schedules.

- Supply PPE: Proper PPE should always be worn on job sites, especially when exposed to hazardous materials and substances. PPE can include chemical protective clothing, gloves, eye protection, and a respirator.

All workers have the right to know what hazards are present on the job site and what they are exposed to. If their job requires them to work with toxic substances, employers are responsible for reducing or eliminating the hazard as much as possible to ensure worker safety. If removing or reducing exposure isn’t possible, ensure proper PPE is provided.

2 comments