May 17, 2024

OSHA rule change on employee representation is effective May 31

A controversial rule change allowing a non-employee to represent employees during an OSHA walkthrough investigation takes effect May 31.

May 16, 2024

Work paused after piece of metal falls at Boston worksite

Work has halted at Boston’s South Station construction site after a steel concrete form fell more than 20 stories, damaging windows but causing no injuries.

May 15, 2024

PCL Construction one of Fortune’s top 100 places to work

Based largely on employee feedback, PCL Construction Enterprises was named Fortune’s Top 100 Places To Work for the second year.

May 15, 2024

Kubota partners with MLB Toronto Blue Jays

Canada is the home of many great construction projects, and a partnership between Kubota and the Toronto Blue Jays aims to keep Kubota’s brand visible…

May 14, 2024

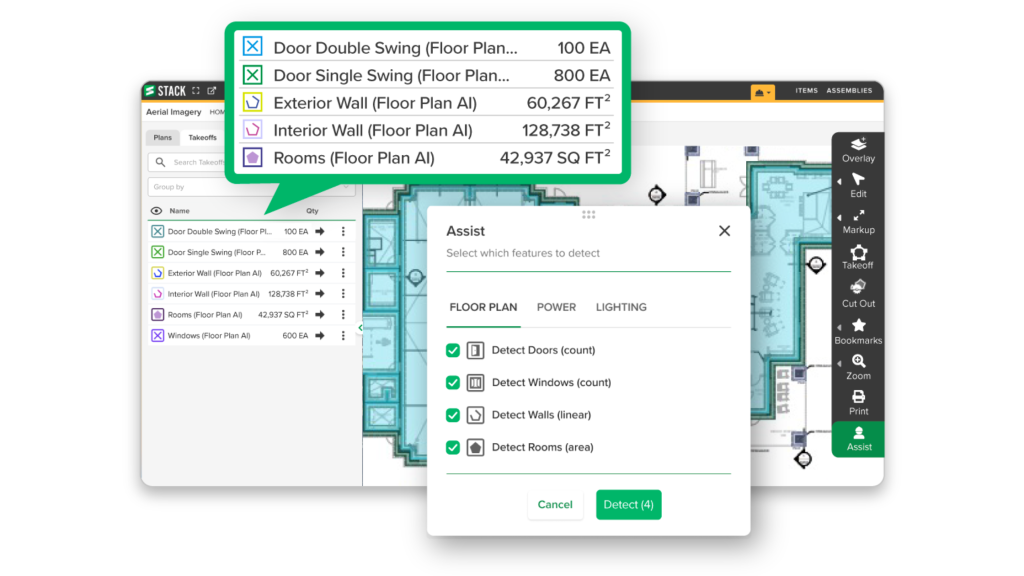

STACK Construction Technologies announces STACK Assist AI feature

STACK’s construction management platform now has AI-generated Takeoff abilities through its STACK Assist feature.

May 14, 2024

BMO Centre expansion is nearly complete, opening set for June

The BMO Centre expansion morphs the venue into a modern entertainment and convention spot. The facility is now an updated pillar of the Arts District.

May 13, 2024

7 money saving tips for contractors

Contractors’ profits are often thin. Avoiding activity lags, using local suppliers, avoiding scope creep, and using tech can help contractors boost profits.

May 13, 2024

Teaching kids their AECs: 10 construction books for kids

Want to teach your child about construction? Pete The Cat: Construction Destruction and Goodnight Goodnight Construction Site are two books to start with.

April 25, 2024

Fall safety violators targeted by OSHA

OSHA has cracked down on fall safety violators and is taking contractors to task over safety violations, sometimes even forcing compliance.

April 25, 2024

Emerging risks outlined in survey

A report from HKA highlights the state of construction disputes around the world—most of which are completely preventable.

April 25, 2024

Ontario to ban discriminatory job posting requirements

Ontario’s government is introducing legislation to help foreign-trained candidates compete for jobs fairly by banning Canadian work experience requirements.