San Francisco-based construction robotics firm Canvas offers a robot drywall finisher that replaces a professional drywaller. Seeing savings for customers and increasing their sales, large contractors and materials suppliers have partnered with the 7-year-old startup.

Founders’ mechanical engineering backgrounds

Canvas’ drywall finishing robot was born from the extensive robotics background of its co-founders, CEO Kevin Albert and CTO Maria Telleria. They hold a master’s degree and a Ph.D. in mechanical engineering from the Massachusetts Institute of Technology (MIT), respectively.

Albert has 20 years of experience in robotics. Telleria is the lead author on eight patents and five patent applications for Canvas systems and is co-inventor on three other patents related to pneumatic robots.

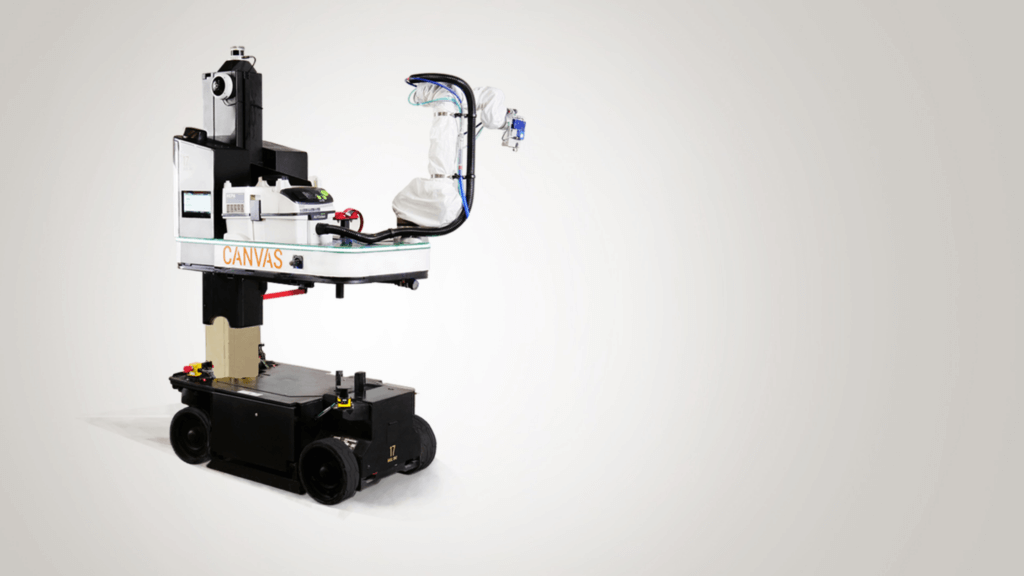

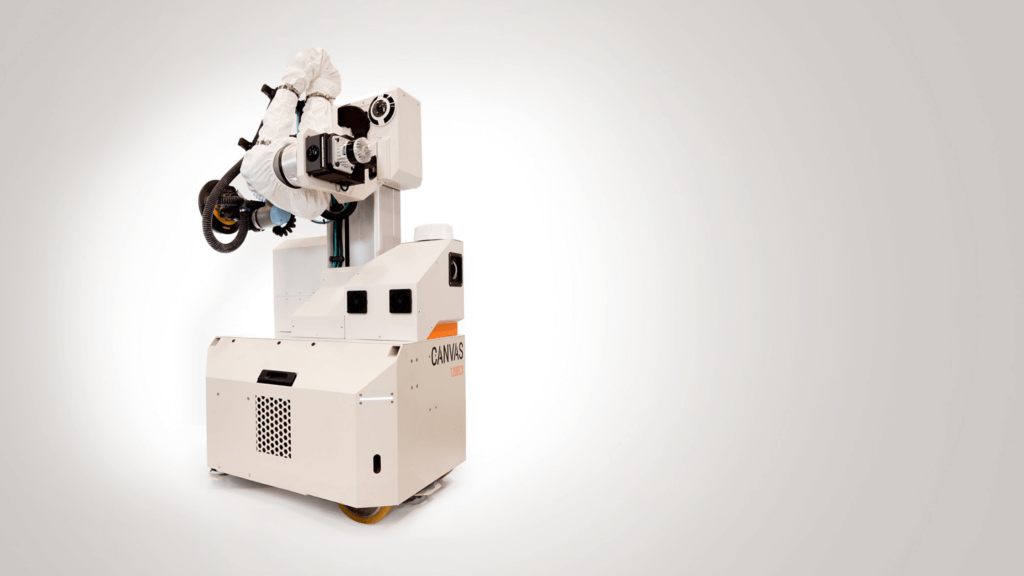

Launched in 2017, Canvas’s technology is intended to mechanize the craft skill of drywall finishing by systematizing how a wall is sprayed and sanded to create a seamless finish. The tool is designed to help contractors complete projects faster, more economically, and with assembly line-type precision.

“Canvas was founded with the motivation to bring advanced robotic tools to construction,” said Telleria. “We are passionate about creating new tools that protect workers from repetitive work, dust exposure, and risk of working at heights.”

Unlike many tech tools for construction, this one was partly informed by Albert’s work in construction in high school and college, as well as the expertise of longtime construction professionals who have helped in the technology’s development.

“Kevin did some construction work in high school and college, so he is aware of how hard it can be on the body. But we also knew that we needed experts to create a robotic solution that really met the needs of the taper. So early on, we brought on both advisors and employees who had construction experience,” Telleria said.

How Canvas works

The Canvas robot uses computer vision and Artificial Intelligence (AI) to recognize different seam and wall types. Operated by a worker, the robot enables workers to produce predictable and consistent finishes in a fraction of the time it takes for a worker to do so manually. The machine also makes the work safer for workers, removing 99% of the dust created with drywall work.

Efficiency is another place the robot shines, enabling workers to finish more drywall in less time without being physically worn out. Repetitive movements in construction, like completing overhead tasks for long periods of time, can lead to physical strain and, sometimes, serious injuries.

For those unfamiliar with drywall finishing, it’s some of the most physically demanding work in construction. It is also dusty and often hot work. The finishing process is itself a semi-craft, requiring a skilled worker to tape, spackle, and sand the seams, ensuring the finish is clean and consistent.

It’s not intended for amateurs, but Canvas’ robots easily tackle the work.

“Our robotic systems have mm-level precision. Most importantly, they produce consistent results,” Telleria said.

Having a robot that can provide Level 4 or 5 finishes without error, as Canvas does, could be a great time- and back-saver for contractors.

Growing corporate partnerships

Industry leaders have embraced canvas technology in contracting, materials supply, and manufacturing. In March 2023, Canvas announced that equipment manufacturer Hilti would produce its robotic machines.

In May 2023, Canvas partnered with USG Corp., a well-known American manufacturer of drywall and other construction materials.

“The partnership leverages two major technical advances: onsite robotics from Canvas and advanced building materials expertise from USG.,” a USG press release said. “These organizations joined forces to collectively innovate and address chronic labor shortages, schedule and budget overruns, quality inconsistencies, and productivity and safety issues that have continuously challenged the drywall industry.”

The partnership enables Canvas to further refine its technology to produce the best customer results.

“The Canvas materials process team has been working with USG for more than a year to enable high-quality surface finishing with current materials and are developing next-generation materials,” said Dr. Srinivas Veeramasuneni, Chief Technology Officer, USG.

In 2022, Daley’s Drywall & Taping, Inc. and Nevell Group Inc. both signed multi-machine, multi-year leases for priority access to the Canvas technology. Since then, the wall and ceiling contractors have operated Canvas robots on their work sites.

”We very clearly see the writing on the wall for the future of the drywall finishing industry,” Daley’s Drywall & Taping Vice-President Jonathan Hughes said in a press release announcing the partnership. “It tells us that we need to embrace automation sooner than later, as in right now.”

1 comment