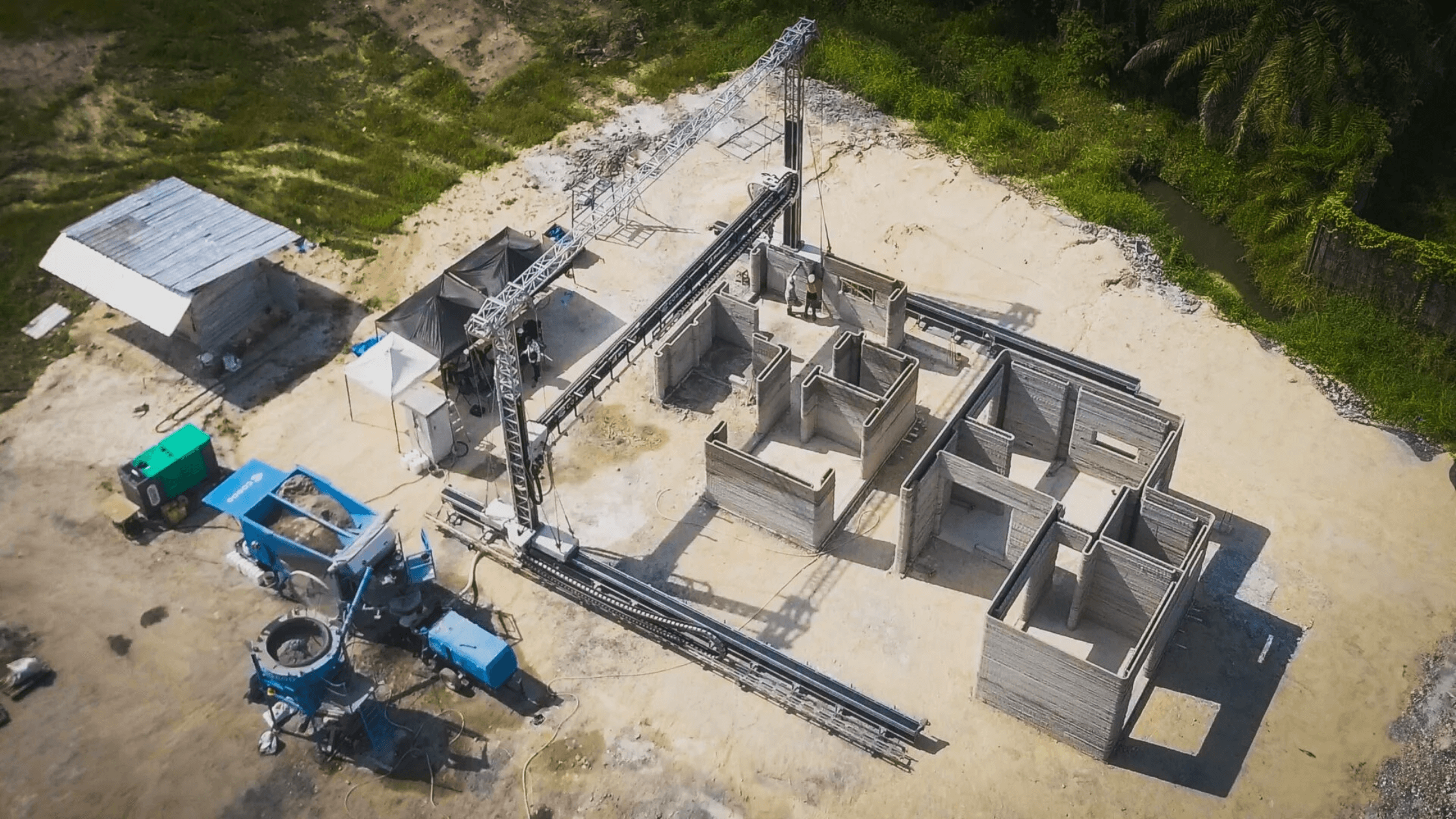

COBOD, a leader in 3D printing for the construction industry, has announced the development of its third 3D printer model, the BOD3 3D Construction Printer. This newest model is set to release with game-changing features, including an extendable ground-based track for continuous printing. It can print multiple buildings at once and also supports printing “real” concrete to support the use of local sand and gravel.

The development of this newest printer stems from COBOD’s desire to optimize printing speed and support high-volume, low-rise construction. Since the BOD3 supports continuous printing, the company expects multi-housing and row-housing to be popular use cases. The speed and efficiency lower downtime between buildings and are expected to lower overall construction costs.

Like the previous iterations, the BOD3 model offers deep customization, allowing it to fit specific size specifications and meet worldwide construction size compliance standards.

“There are fewer columns to be set up, so overall it is just a simpler and more efficient process,” said Jonathan Riise, Head of Research and Development at COBOD. “The BOD3 will definitely help with low-rise residential construction. From what we’ve seen in research and statistics, there’s a need for low-story buildings, because people are in need for proper homes. Homes that are built to last!”

The 3D printer and supplementary equipment are operated and monitored from a single system. The transport of the printable materials is made by the Advanced Hose Management System (AHMS), which transports the materials delivery system to the printhead thanks to hoses stabilized with E-chains. This reduces physical labor for workers and maximizes printed material flow.

The BOD3 has been globally tested and is already operational in Indonesia, Angola, and Bahrain.

Subscribe to our weekly newsletter to stay in the loop on construction industry innovation.