The building industry is undergoing major changes as companies seek profitability, increased sustainability, and new methods to make building easier and more efficient. Drones, sustainable concrete alternatives, virtual training simulators, and prefabrication are just some of the construction trends in 2025 the industry will see boom in 2025. Adapting to new means of building could mean greater productivity, enjoyment, and sustainability for the industry.

Top construction trends to watch in 2025

1. Construction technology trends and AI are on the rise to battle labor shortages

Workforce issues have been prevalent across the construction industry for years. With talent shortages a lingering concern (including skilled labor shortages), increased construction costs and delays follow.

Integrating AI-enabled automation and digital tooling increases workforce productivity, allowing workers to focus on higher-value tasks. Managers can also do less administrative or digital tasking and focus more on the site. Leveraging technology can also slow the need for new admin hires, and AI-powered machines and equipment could attract a younger labor force.

2. Drone use will become more common on each site

Drone technology is another way the construction industry is increasing efficiency. Initially considered a novelty gadget, drones are now a significant cost savings on major projects.

Drone use has dramatically reduced waste, with a significant dent in the annual $160 billion in waste currently occurring on site. Drones more accurately measure material stockpiles, improving measurement accuracy by 61%. This leads to more effective production and manufacturing processes, producing only what is needed, with less excess going to waste.

Drones can also improve safety measures on site by better inspecting various locations without potentially putting real workers in harm’s way. Although drones as a safety tool are still a relatively new concept, the construction industry has seen an increase in safety standards by 55% so far.

3. Green construction trends and sustainability initiatives will grow

Green construction and sustainable building refer to constructing environmentally sustainable buildings using sustainable processes and design. According to Dodge’s World Green Building Report, respondents say approximately half of all design and construction should be green by the year’s end.

Energy efficiency is now considered a top practice by home builders to boost eco-friendly home performance. Many consumers and home buyers express that green building or energy-efficient home performance is a main selling point, and this demand drives the residential home building sector to make advancements and new commitments to green initiatives.

4. New trends in construction materials, like 3D printing, will become more common

3D printing has blown up in the construction market in recent years, with construction companies producing buildings through printing with concrete, geopolymers, sand, fiber, and other materials.

Some companies have even used biodegradable materials like soil, mud, and straw in 3D-printed homes. Typically, only the frames and walls are manufactured using 3D printing techniques, but recent innovations have included the 3D printing of electrical fixtures and plumbing spaces.

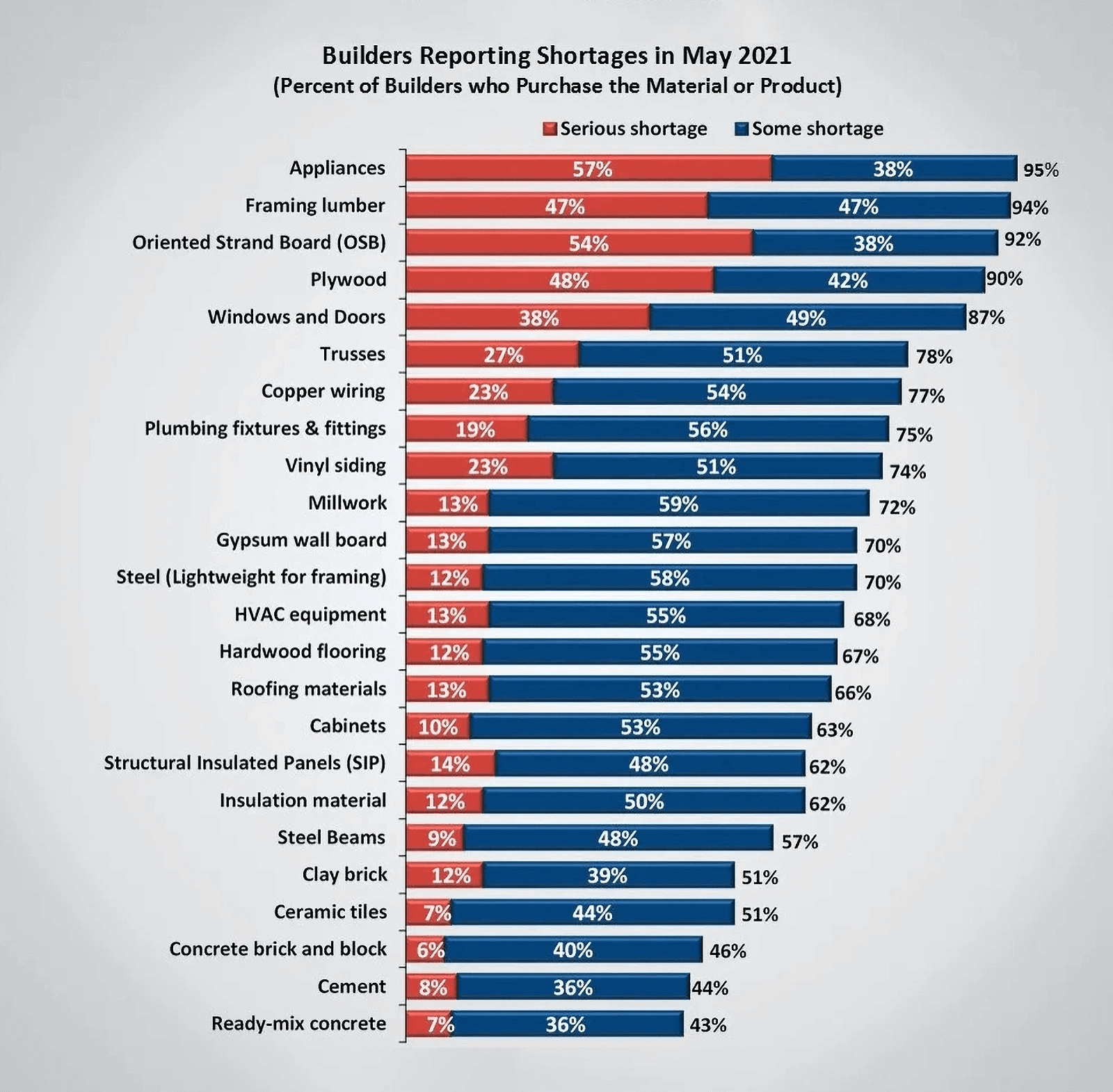

5. Building material costs will soar

Building materials are becoming more scarce for many companies across North America. More than 90% of builders say they’re facing a materials shortage. In the same survey, 70% also said most shortages are related to appliances, plywood, and oriented strand board. With Trump’s tarifs on Canada, Mexico, and China in full effect, this will be one construction trend in 2025 you’ll want to keep your eyes on.

Source: https://explodingtopics.com/blog/construction-industry-trends

With the housing market demand rising, building material costs rise with it. In mid-2022, the Associated General Contractors of America released data showing that construction material costs used in non-residential projects had risen nearly 17% compared to the previous year. Plastic construction products, asphalt roofing materials, and diesel fuel have seen some of the highest price increases. Steel and aluminum have also seen dramatic increases.

6. Virtual construction becomes more mainstream

Building Information Modeling (BIM) and construction project management software have experienced an upswing in recent years, but most significantly, virtual design and construction (VDC).

Google search growth for “construction management software” is up 133% in 10 years. Source: https://explodingtopics.com/blog/construction-industry-trends.

The growing use of virtual environments for construction companies has increased sustainability, accessibility, and training and safety protocols. They can be accessed on computers, phones, tablets, and sometimes as full virtual reality hardware.

Companies and workers cite its effectiveness in educating workers and reducing overhead costs of using actual sites and equipment for training. It’s also much safer and is said to be a fun, effective means of training and education.

7. More companies will lean into robotics

Automation and robotics are gaining traction rapidly with many new innovations being created daily that improve efficiency on many fronts making it one of the most exciting construction trends in 2025. For example, some firms incorporate robots in the transport process with layout planning, welding, or for remote operation in hazardous environments.

Some have even used robots for building envelope construction, reducing crew safety risks and combating the labor shortage simultaneously. With the integration of AI, these robots can be programmed to perform new tasks, creating smarter, evolving technologies and paving the way for future automated systems. While they have a higher upfront cost, working with a reduced headcount and lowering your materials costs means the robots pay for themselves in the long term.

8. Self-replicating concrete and biocement will replace more concrete

Cement production is one of the main targeted areas of the living material sector. Production alone makes up nearly 8% of CO2 emissions globally, and total emissions must fall by 16% before 2030 to align with the Paris Agreement on climate change.

Biocement and the use of other cementous materials have been increasingly popular. Biocement is grown using natural materials instead of being created from non-renewable ones. This process also absorbs CO2 instead of emitting it, and the building materials self-replicate in the “manufacturing” process.

9. Modular and prefabrication work grows

Modular and prefabricated construction refer to specific components of a structure that are preassembled or manufactured off-site. Once constructed, these components are transported to the project and easily affixed to the building. The global market for modular construction was worth roughly $91 billion in 2022 and is expected to grow to $120.4 billion by 2027.

Source: https://explodingtopics.com/blog/construction-industry-trends

Construction companies, architects, and workers cite modular construction and prefabrication as ways to keep project costs low, reduce waste, and shorten the completion timeline.

10. Safety materials will see a tech upgrade

In recent years, safety training techniques and protocols have been revamped in pockets of the construction industry, but the PPE itself is expecting a upgrade.

Hard hats have long been used on sites worldwide over the last several decades, and new safety helmets are becoming popular for good reason. The new style is similar to rock climbers’ hats, and the chin strap helps the hat stay on in the event of a fall.

Helmets like the ones from HexArmor use Kinetix suspension systems that absorb impact and direct it away from the spinal cord and neck. Compared to traditional construction hard hats, these helmets reduce impact force by about 40%. Their greater field of vision and ergonomic fit make them more suitable for every worker.

Final thoughts

The construction industry is constantly evolving as the market demands grow and shift. The upsides mean more sustainability, tech, and efficiency, but the downsides include battling the labor shortage and dealing with increased materials costs.

Timeliness and quality are important for project completion. Still, if your construction company doesn’t embrace technology, new materials, virtual processes, or prefabrication, it could risk falling behind the times.

Looking to stay in the loop about news, trends, and findings in the construction industry? Subscribe here, and get updates right to your inbox.

2 comments