TyBOT ties rebar, SAM lays bricks, and Dusty Robotics are the latest construction robots looking to change the way construction is done. With more than 80% of contractors struggling to find skilled labor and project delays costing billions annually, construction robots are stepping in to keep timelines on track and workers out of harm’s way. From skyscrapers to housing developments, these robots are handling the grunt work so humans can focus on the big picture.

Robotics in the construction industry: The new trend

The construction industry has long struggled with significant labor shortages. It’s currently estimated that an additional 439,000 workers will be needed to meet project demands in the United States alone. This shortage is due in part to an aging workforce and a decline in young entrants into the trades.

At the same time, construction projects are becoming more complex, requiring greater integration of advanced technologies. Construction robots offer an innovative solution to these challenges by addressing the following:

- Speed: Robots can operate continuously, reducing project timelines

- Accuracy: Automation minimizes errors, leading to less rework

- Safety: Robots can perform dangerous tasks, decreasing the risk to human workers

- Cost savings: While there’s a significant up-front investment, there are substantial long-term savings in labor and reduced human error

The adoption of robotics in the construction industry is steadily increasing. What began as pilot projects is now reality with companies investing in automation for tasks like rebar tying, bricklaying, and site layout.

8 groundbreaking construction robots

1. TyBOT by Advanced Construction Robotics

Image of TyBot in action sourced from Advanced Construction Robotics

Tying rebar is repetitive, time-consuming, and tough on the body, but TyBOT is built for exactly that. Developed by Advanced Construction Robotics, this robot scans horizontal rebar mats and autonomously ties intersections quickly and precisely. It’s already used on bridge decks and other large horizontal concrete projects, helping contractors keep schedules tight and reducing strain on their crews.

2. SAM (Semi-Automated Mason) by Construction Robotics

Laying bricks by hand is tough work, especially over long hours and high walls. That’s where SAM comes in. Short for Semi-Automated Mason, this construction robot was developed by Construction Robotics to assist human masons by placing bricks in sequence. At the same time, workers can focus on finishing tasks like setting and tooling. SAM can lay over 3,000 bricks a day, about three times the output of a human, making it a valuable asset in commercial buildings, schools, and mid-rise projects.

3. Liftbot by KEWAZO

Moving materials up and down scaffolding usually takes a team, but Liftbot does the job with just one operator. Created by KEWAZO, this compact robotic lift automates vertical transport on construction sites to reduce the number of workers needed and cut down on risky manual lifting. It’s especially useful for façade work, industrial sites, and projects where space and labor are tight.

4. Baubot by Printstones

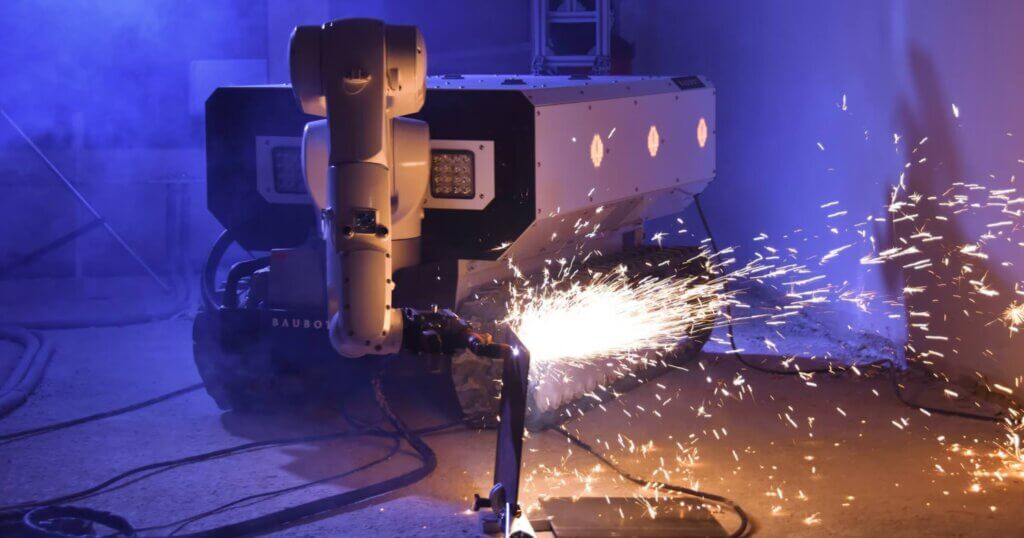

Baubot in action cutting a metal pipe. Photo sourced from Baubot.com

Think of Baubot as a jobsite multitasker on wheels. Developed by Austrian company Printstones, this autonomous mobile robot can assist with a wide range of construction tasks, including carrying tools and materials, helping with layout, and even 3D printing. While it’s still in development, the vision for Baubot is ambitious: a flexible, all-in-one assistant that can adapt to different phases of complex builds. It’s a glimpse into what a more collaborative, tech-enabled jobsite could look like.

5. Hilti Jaibot

Overhead drilling is one of the most physically taxing tasks on a job site, so Hilti built a robot to handle it. Already gaining traction on major commercial projects, Jaibot is a semi-autonomous drilling assistant that uses BIM data to locate, mark, and drill anchor points for MEP installations with impressive accuracy. Mounted on a mobile platform, it navigates the site and works safely alongside human crews, dramatically reducing physical strain and improving consistency in ceiling installations.

6. HP SitePrint

Image sourced from HP.com

Site layout can be time-consuming and error-prone, but HP’s SitePrint is changing that. This autonomous construction robot prints digital blueprints directly onto floors with ink, translating CAD files into real layouts with incredible accuracy. It handles everything from walls and electrical to plumbing guides, reducing layout time from days to a few hours. Ideal for commercial buildings and large-scale residential projects, SitePrint helps eliminate rework, speed up framing, and keep teams aligned from the ground up.

7. Hadrian X

Hadrian X is changing the face of robotic masonry. Developed by Australian company FBR, this massive robotic arm can lay up to 1,000 bricks per hour with high precision, all guided by CAD data. Once the digital design is uploaded, Hadrian X calculates the most efficient path and gets to work, automatically cutting, positioning, and placing each brick. It’s engineered for residential and low-rise commercial construction, where speed and consistency can drastically reduce timelines and material waste.

8. Dusty Robotics

Dusty Robotics has reimagined the site layout with the FieldPrinter. This autonomous robot prints accurate layout markings directly onto concrete slabs, eliminating human error and speeding up the framing process by several days. Contractors using the FieldPrinter report time savings and less rework, especially on large-scale builds with complex floor plans. It easily integrates with BIM models, making it ideal for MEP workflows, where precision matters.

Are construction robots coming to a site near you?

Construction robots have progressed from cool tech demos to valuable tools on modern job sites. As the technology improves and costs come down, expect to see more all-in-one bots that can drill, lift, layout, and even build entire walls, all while syncing with BIM models and digital twins. Some construction robots already provide powerful prefabrication solutions, while others push boundaries in everything from automated design to road repair and elevator installation. These companies are rethinking how we build, from the first layout line to long-term maintenance.

If you’re as fascinated by jobsite automation as we are, subscribe to our newsletter for more stories like this.

1 comment