Raise Robotics’ mission is simple: build robots that enable safer job sites. Established in 2021 by cofounders Gary Chen and Conley Oster, their robots support construction workers by taking on dangerous and repetitive tasks on commercial worksites. These robots can install brackets on facade panels by completing the layout, installation, and inspection in a fraction of the time a regular team can, saving companies time and money.

Raise Robitics’ technological solutions are designed to help alleviate the industry’s worker shortage, improve safety by reducing worker presence in dangerous situations, and reduce overhead costs.

Best of all, it all started with a LinkedIn Message.

A connection request today, a company tomorrow

The Raise Robotics founding story started with Gary contacting Conley on LinkedIn. Gary had been working on autonomous vehicles at Waymo, and Conley had years of experience in crane operation and construction equipment and was working on specialized construction projects.

While very different, the combination of backgrounds converged beautifully. Gary hadn’t reached out with the intent to start a company but simply to inquire about construction challenges in dense housing development. What they ended up with was a way to revolutionize building envelope installation.

Fast-forward to today and Raise Robotics is filling the gap. It’s estimated that the construction industry is short about 650,000 skilled workers, which results in construction delays, costing companies millions. Raise Robotics’ robots are designed to improve job site efficiency by reducing an entire crew (6-8 people) to just a single operator—and they do the work faster, freeing up time and labor for other tasks. While quality control and safety are the primary drivers for Raise Robotics, the increased efficiency output is a bonus.

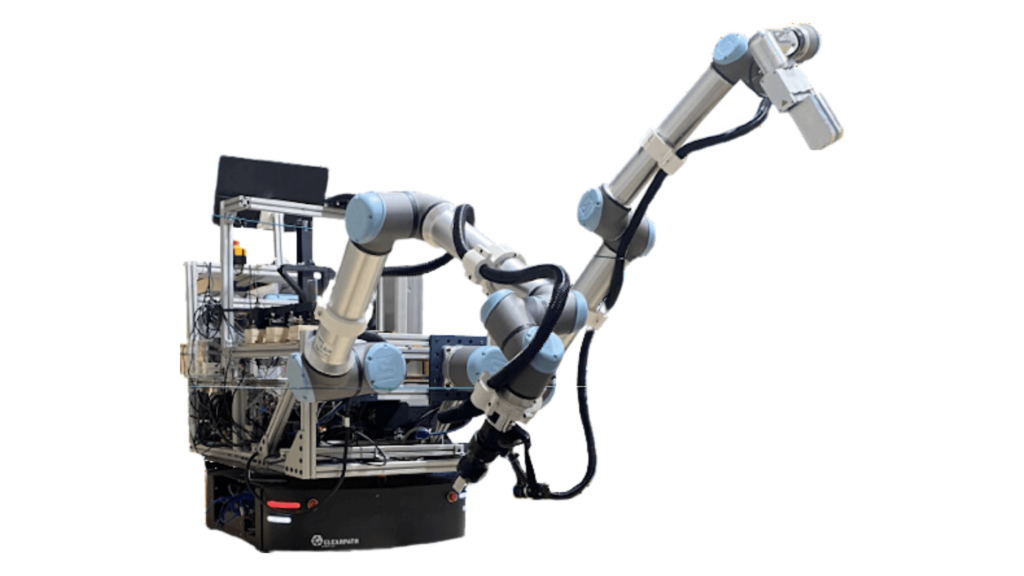

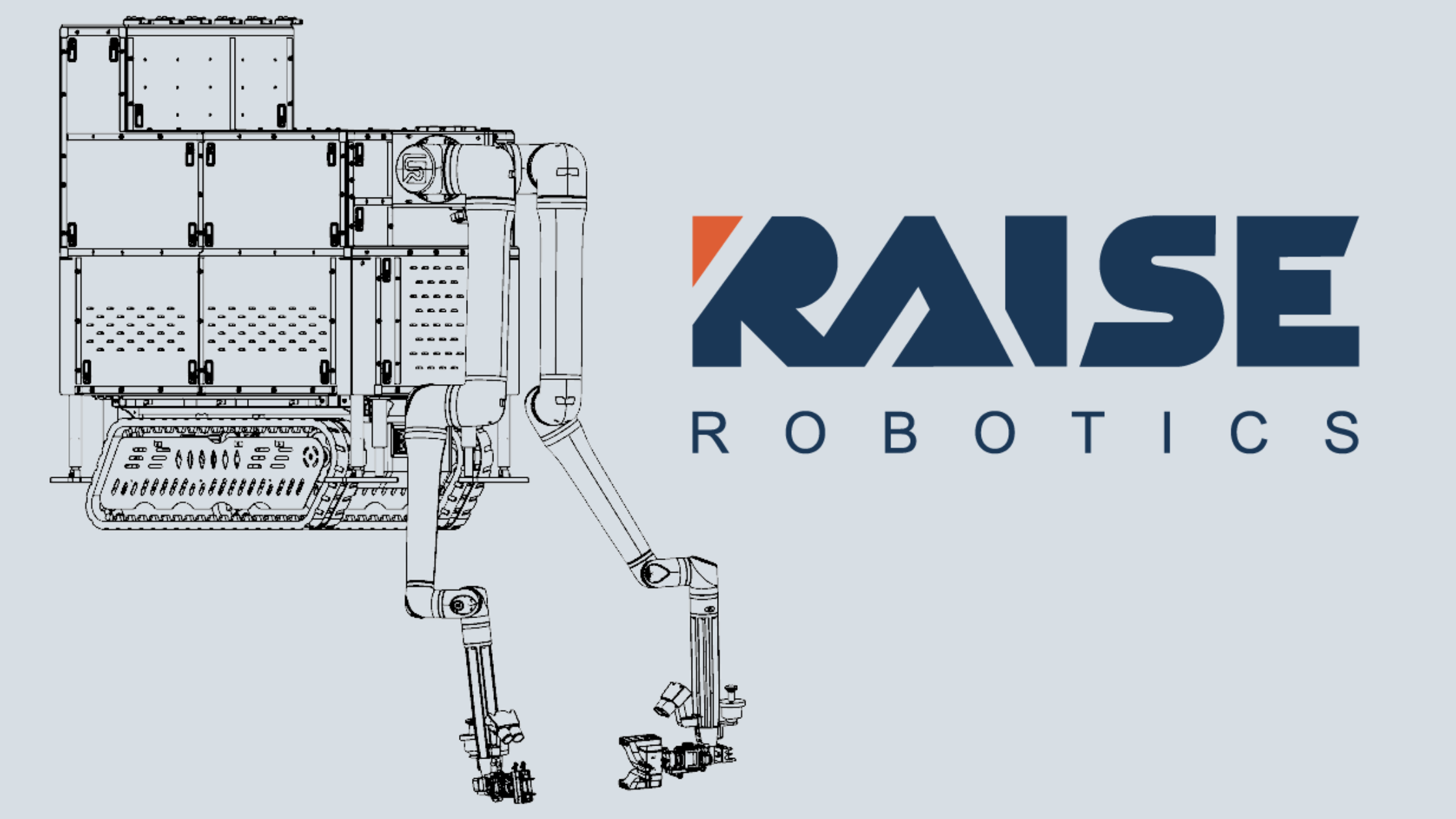

Robot Specs

Raise Robotics machines are designed to produce building envelopes—everything that wraps a building’s exterior. Traditionally, workers in compromised positions over the edge of the building install the facade brackets. By having the robots work around the edges, safety is increased without sacrificing the quality of the installation.

These robots have:

- A 57” maximum vertical reach

- An 80lb payload

- A 68” maximum horizontal reach

The robots can handle object manipulation, driving, layout, drilling, and welding. Essentially, they equip contractors with an extra set of hands, helping companies build better by ensuring high-quality construction and safer job sites.

With Raise Robotics machines, jobsites become easier, safer, and produce better and more consistent results.

To stay in the loop about companies changing the construction industry, subscribe to our newsletter.

1 comment