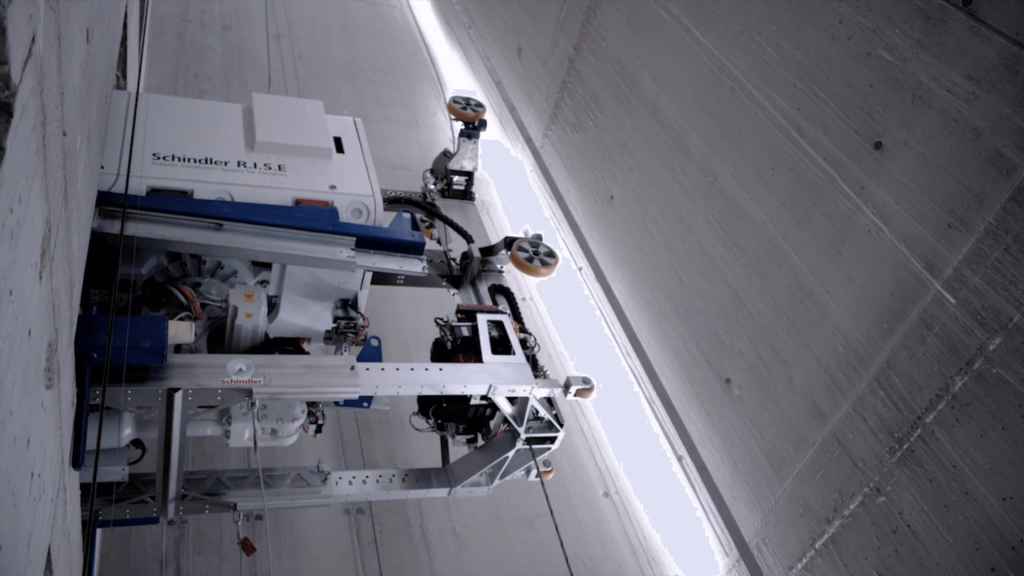

Schindler, a global leader in elevator and escalator manufacturing, has introduced groundbreaking technology transforming elevator installation on construction sites. Known as Schindler R.I.S.E. (Robotic Installation System for Elevators), these autonomous robots provide a more efficient, safer, and precise method for installing elevators in high-rise buildings.

Schindler’s revolutionary robotic installation system, Schindler R.I.S.E., can execute elevator installation steps autonomously while improving working conditions. Video source: Schindler.

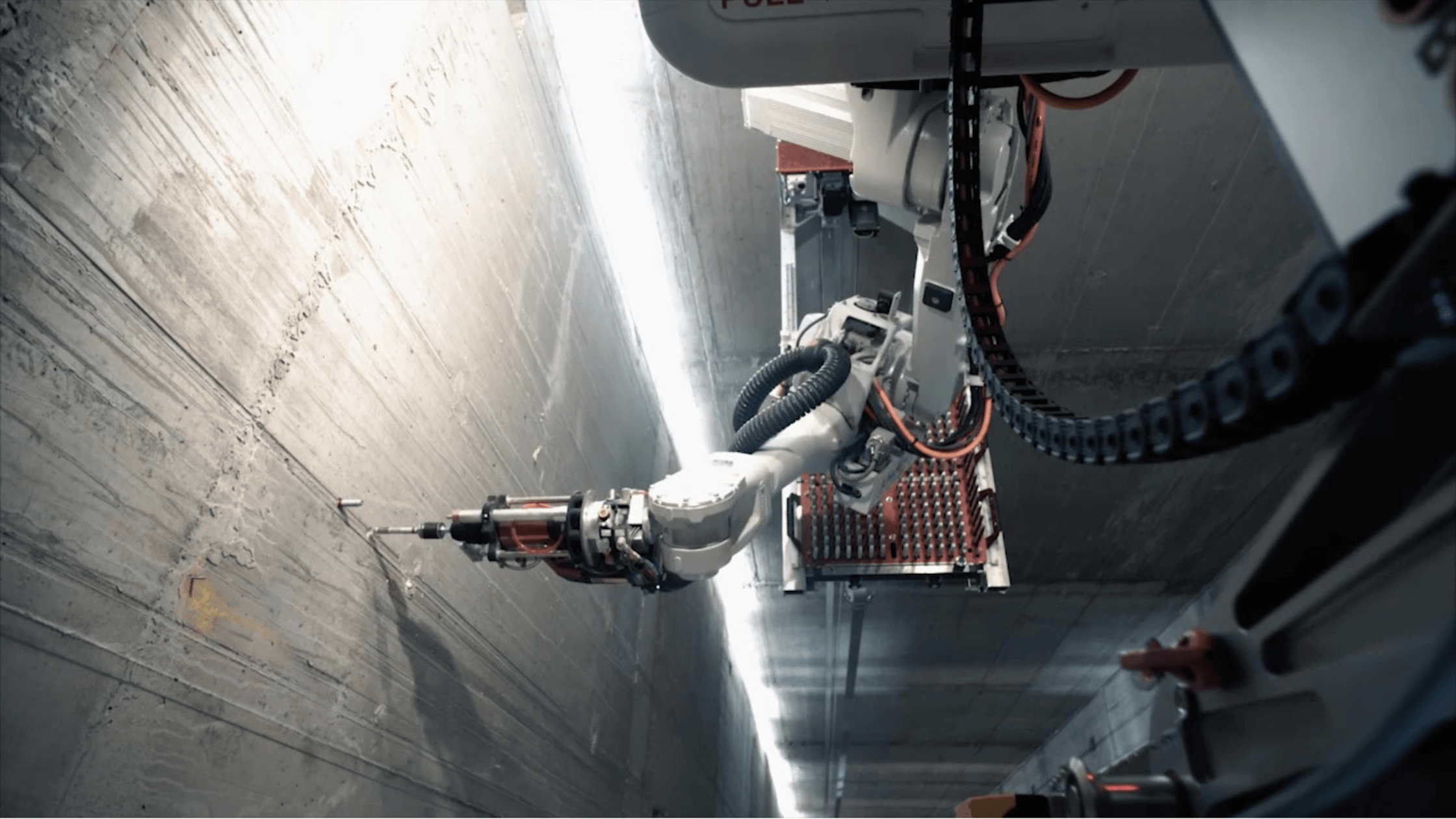

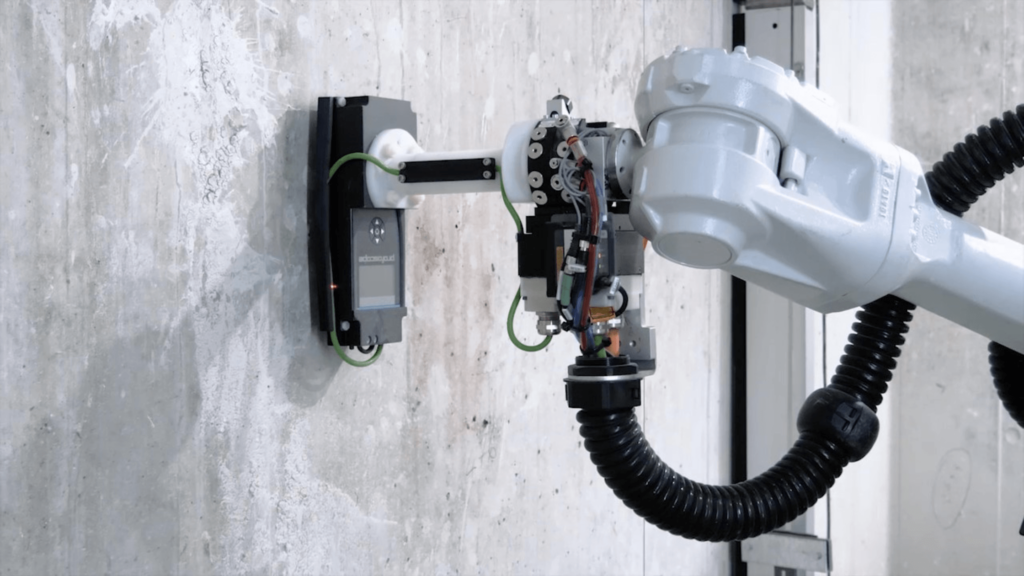

R.I.S.E. robots use advanced automation to drill holes, set anchors, and position guide rails with pinpoint accuracy. This automation eliminates common human errors and streamlines the traditionally labor-intensive installation process, enhancing overall quality. These robots work directly from digital building plans, allowing for seamless integration with the broader construction workflow.

The benefits of Schindler R.I.S.E. extend beyond just precision. By reducing the need for manual labor in hazardous situations, they significantly improve on-site safety. This is especially crucial in high-rise construction, where working at heights poses significant risks.

Typically, installing an elevator takes around a week per floor. While project timelines can vary, Schindler asserts that their R.I.S.E technology significantly speeds up this process, reducing installation time and resulting in faster project completions and lower costs. With a more efficient installation process, building operations can commence sooner, providing value to developers and tenants alike.

Five R.I.S.E robots are already deployed, helping build skyscrapers worldwide, including Dubai’s 340-metre Uptown Tower, Brazil’s JK Square, and Warsaw’s Varso Tower.

Incorporating R.I.S.E. technology into elevator installation is a leap forward for the construction industry. It exemplifies how robotics and automation can enhance quality, safety, and efficiency, setting new standards for building projects globally.