Airports are no longer just places to catch flights—they’re turning into digital ecosystems where construction, data, and technology meet. From automated baggage handling to predictive maintenance systems, smart airports are setting the new standard for infrastructure design and management. For contractors, building the future of aviation means integrating sensors, networks, and software alongside concrete and steel. The construction focus is moving towards creating connected environments that make travel smoother and operations more efficient. Knowing how this is unfolding means contractors can prepare for the next major airport projects.

Quick look

- Smart airports are shifting from traditional infrastructure to connected, data-driven environments using AI, sensors, and automation.

- McKinsey reports that digital transformation can boost airport EBITDA by 6–8% through better asset performance and reduced downtime.

- Contractors now need digital expertise—installing IoT networks, automation systems, and data cabling alongside physical infrastructure.

- Leading airports like Changi, Hamad International, and Heathrow are setting global examples with biometric systems, AI maintenance, and digital twins.

- Understanding how digital and construction systems integrate will position contractors for upcoming airport projects worldwide.

The rise of smart airports

Smart airports are changing the way the construction industry approaches aviation infrastructure. Instead of just terminals, runways, and parking decks, projects now include digital layers—including IoT networks, AI-driven systems, and automated equipment—that connect every aspect of airport operations. These systems help improve safety, reduce wait times, and support predictive maintenance, thereby lowering costs and enhancing the passenger experience.

According to McKinsey & Company, airports that invest in digital transformation can increase their Earnings Before Interest, Taxes, Depreciation, and Amortization (EBITDA) by 6–8%, mainly due to better asset management and faster decision-making. The construction phase plays a large role in that improvement. When digital infrastructure is included from the start—integrating sensors, data cabling, and connectivity hubs—the airport’s long-term performance improves dramatically. For general contractors, MEP teams, and engineering firms, this means that future bids will require both physical and digital expertise.

Technologies driving the transformation: AI and predictive analytics

Artificial intelligence and predictive analytics are now central to airport modernization. From optimizing flight scheduling to managing HVAC loads, data-driven systems are changing how airports are built and maintained. Contractors who understand how these technologies integrate into the built environment will have a significant advantage in securing contracts over the next decade.

Digital twins and simulation tools

Digital twins enable airports to model every aspect of their operations—from terminal crowd flow to baggage conveyor speed—in a virtual environment. This allows contractors to see and test how design choices will impact energy usage, maintenance cycles, and passenger comfort before construction even begins. Simulation tools also let project teams evaluate construction sequences, reducing downtime during renovations or expansions. Many large airports now require digital twin modeling as part of their design-build specifications, so contractors with experience in 3D modeling and data integration will be in higher demand.

Internet of Things (IoT) and sensor networks

Smart airports are IoT-heavy. Sensors monitor lighting, occupancy, baggage systems, air quality, and water usage in real time. For contractors, this means planning for embedded sensor placement during construction, making sure cable runs and access points are included early in the design. Electrical and HVAC contractors in particular must understand how these systems communicate through data networks, not just mechanical components. Installing sensor-ready infrastructure reduces rework and supports long-term adaptability as new systems come online.

Automation and robotics

Automation is becoming standard across airport operations. Autonomous ground vehicles move luggage and cargo, robotic cleaning units clean terminal floors, and AI-powered security gates manage biometric access. These upgrades require new kinds of mechanical, electrical, and control system planning. Contractors must work closely with equipment suppliers and IT specialists to ensure that hardware and software integrate seamlessly. The shift to automation doesn’t just change what is built; it changes how it’s built, with modular installation, embedded control units, and digital commissioning becoming routine parts of airport projects.

Implications for contractors

Smart airports require a new approach to construction delivery. Projects now combine physical infrastructure with complex digital systems, requiring collaboration between construction, IT, and airport operations teams from the outset.

Contractors working on smart airport projects should:

- Integrate technology planning into the early design phases, particularly for data infrastructure and cabling routes.

- Coordinate with system integrators who specialize in IoT, building management, and automation systems.

- Include commissioning protocols for both mechanical and digital systems before handover.

Traditional scopes of work are expanding. Electrical contractors may now be installing sensor networks or fibre backbones. HVAC specialists may need to work with building automation teams to ensure systems talk to AI-based controls. Civil contractors may be incorporating underground fibre ducts and smart drainage sensors. The lines are blurring, and the teams that adapt fastest will win more work.

Another big consideration is early alignment with the airport operator’s digital strategy. Too often, contractors install physical systems that aren’t compatible with the airport’s preferred data platforms. This leads to expensive retrofits and change orders. Establishing coordination protocols early, before the design is finalised, avoids this risk and keeps the project on track. Contractors who bring digital literacy to the table will stand out to owners seeking partners who understand how technology affects lifecycle value.

Smart airports also change maintenance and warranty expectations. Systems now generate their own diagnostics and feed data into predictive maintenance software. Contractors may need to provide data integration support or partner with analytics firms for post-construction services. This creates ongoing business opportunities beyond construction but also requires knowledge of cybersecurity, data access, and long-term monitoring systems.

Global leaders setting the pace for building smart airports

Changi Airport, Singapore

Changi Airport is leading the way with biometric check-ins, automated immigration gates, and autonomous cleaning vehicles that keep its terminals running 24/7. Contractors working on Changi’s expansions need to coordinate complex networks of sensors, digital systems, and automated hardware without disrupting passenger flow. These upgrades show how digital infrastructure can enhance both efficiency and traveler comfort when planned into the construction process.

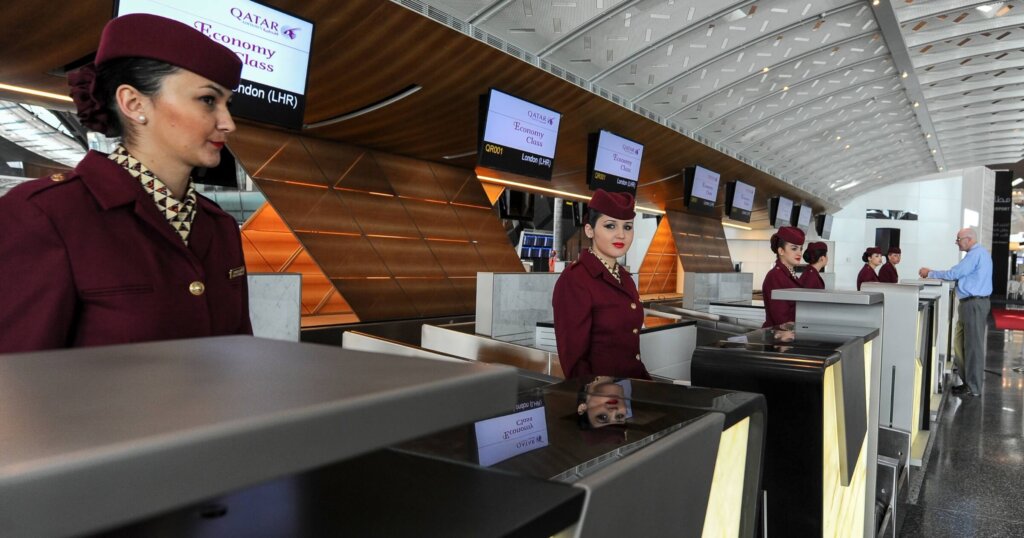

Hamad International Airport, Qatar

Hamad International Airport integrates AI-driven maintenance and predictive analytics to manage its massive HVAC and baggage systems. Contractors building or upgrading facilities here work with AI platforms that continuously assess mechanical performance and flag potential issues before they cause downtime. This has redefined how preventive maintenance is handled, requiring MEP teams to understand data connectivity and analytics-driven control systems as part of their installations.

Heathrow Airport, United Kingdom

Heathrow Airport is developing a digital twin of its infrastructure to improve planning and project coordination. The system enables real-time monitoring of assets, enabling more precise maintenance scheduling and construction project sequencing. Contractors working with Heathrow’s digital team must integrate building data directly into the twin during construction, which helps reduce rework and supports better long-term asset management. Heathrow’s use of digital twins also offers a model for how older airports can modernize without full reconstruction.

Final thoughts

Airports are shifting from static buildings to responsive environments that use data to anticipate needs and optimize performance. For contractors, this is the next stage of complex infrastructure work—where concrete and code come together. Those who incorporate digital understanding into their skill set will be well-positioned for long-term growth as aviation rebounds and new smart airport projects emerge globally.

If you work in construction, engineering, or architecture and want to stay current on how digital infrastructure is changing the industry, subscribe to our newsletter at Under the Hard Hat. It’s where we cover how technology and trades are building the future—one project at a time.