Thanks to AI-powered robots, construction projects are getting smarter, faster, and safer. These machines tackle everything from heavy lifting to precision drilling, helping companies work more efficiently while filling critical labor gaps. Automation takes on repetitive and hazardous tasks, allowing workers to focus on higher-value responsibilities, reducing injuries and cutting project timelines. From self-driving excavators to layout-marking bots, AI and robotics transform how buildings, bridges, and infrastructure come to life.

Quick look

- Automation revolutionizes construction by tackling labor shortages, reducing injuries, and accelerating project timelines.

- Robots, from autonomous excavators to layout-marking bots, handle tasks like drilling, paving, and rebar tying with precision.

- Machines like ABB’s autonomous drilling robot and Boston Dynamics’ Spot enhance accuracy, productivity, and worker safety.

- AI-driven automation is cutting costs, improving sustainability, and setting new standards for precision and efficiency in the industry.

How robotics and AI are changing construction

AI-powered robotics are transforming the construction industry by enhancing precision, addressing labor shortages, boosting safety, accelerating project timelines, reducing costs, and enabling remote operations.

- Enhancing precision: Robots equipped with advanced sensors and AI algorithms perform highly accurate tasks, minimizing errors in measurements, drilling, and installations. For instance, ABB’s autonomous drilling robot scans surfaces to detect hidden rebar and adjusts drilling coordinates accordingly, ensuring millimeter-level precision.

- Tackling labor shortages: Automation helps bridge the gap in skilled labor, keeping projects on track despite workforce challenges. Robots can take over repetitive and physically demanding tasks, allowing human workers to focus on more complex activities. This approach supplements the existing workforce and attracts a new generation of tech-savvy professionals.

- Boosting safety: Construction sites are among the most hazardous workplaces, with risks such as falls, heavy equipment accidents, and exposure to harmful materials. Robots reduce the need for human workers in dangerous environments by performing high-risk tasks like demolition, welding, and inspections in unstable structures. This lowers injury rates and creates a safer work environment. Teleoperated robots allow workers to control machinery from a safe distance, enabling precise control over construction activities without compromising safety.

- Speeding up projects: AI-driven automation increases productivity by performing repetitive or labor-intensive tasks more quickly than human workers. For example, robots can work continuously without fatigue, significantly reducing project timelines and improving overall efficiency. Systems like autonomous layout robots can complete tasks in hours instead of days, keeping construction schedules on target.

- Lowering costs: By automating manual processes, robotics reduce labor costs and optimize resource allocation. AI systems can accurately predict material needs, minimizing waste and ensuring cost-effective construction practices. By reducing reliance on manual labor, robots help reduce wage expenses while improving productivity. A single robotic system can now complete tasks like bricklaying, rebar tying, and layout marking, which traditionally require multiple workers. This translates into long-term cost savings for construction firms.

- Increasing accuracy: Human error in measurements, drilling, and layout planning can lead to costly mistakes and project delays. Robots eliminate these risks by executing tasks precisely, following digital blueprints and AI-driven guidance. For example, robotic layout printers ensure the exact alignment of structural elements, minimizing costly rework.

- Sustainability gains: Construction waste is a primary environmental concern, but robots help optimize material usage by cutting with precision and reducing overuse. AI-powered systems can analyze data to improve resource allocation, leading to more sustainable building practices. Additionally, automation helps create energy-efficient buildings by improving structural integrity and reducing construction waste.

Types of robots used in construction

AI-powered robots offer a range of functionalities that enhance efficiency, safety, and precision. These robots can be categorized into three main types: semi-autonomous, autonomous, and teleoperated.

Semi-autonomous robots

Semi-autonomous robots operate with human oversight but can perform tasks with minimal direct input. They are designed to assist workers by taking over repetitive or strenuous activities, thereby reducing physical strain and increasing productivity.

- Robotic arms for bricklaying: Machines like Fastbrick Robotics’ Hadrian X can accurately lay bricks, significantly accelerating the building process.

- Automated paving machines: These robots automate the process of laying pavements, ensuring consistent quality and reducing manual labor.

- Exoskeletons: Wearable robotic suits enhance worker strength and endurance, enabling them to handle heavy tools and materials more efficiently.

Autonomous robots

Autonomous robots are fully AI-powered and can complete tasks independently using sensors and machine learning algorithms. They navigate and perform functions without human intervention, making them ideal for repetitive or hazardous tasks.

- Autonomous drilling robots: ABB’s autonomous drilling robot can precisely drill holes in elevator shafts, improving installation accuracy and safety.

- 3D printing construction bots: These robots can construct building components or entire structures by layering materials based on digital designs, offering innovative solutions for complex architectural projects.

- Self-navigating site survey drones: Equipped with advanced sensors, these drones autonomously map construction sites, providing real-time data to inform project planning and monitoring.

Teleoperated robots

Teleoperated robots are controlled remotely by human operators, allowing for precise manipulation of machinery from a safe distance. This capability is particularly valuable in environments that are hazardous or difficult to access.

- Demolition robots: Operators can remotely control these machines to dismantle structures, minimizing the risk to human workers in unstable environments.

- Underwater construction robots: These robots are used for tasks like inspecting and repairing underwater infrastructure, and they are operated remotely to perform complex tasks beneath the surface.

- Tunnel boring machines: Teleoperation allows for controlling machinery that excavates tunnels, ensuring precision and safety in subterranean construction projects.

Top AI-powered robots revolutionizing construction

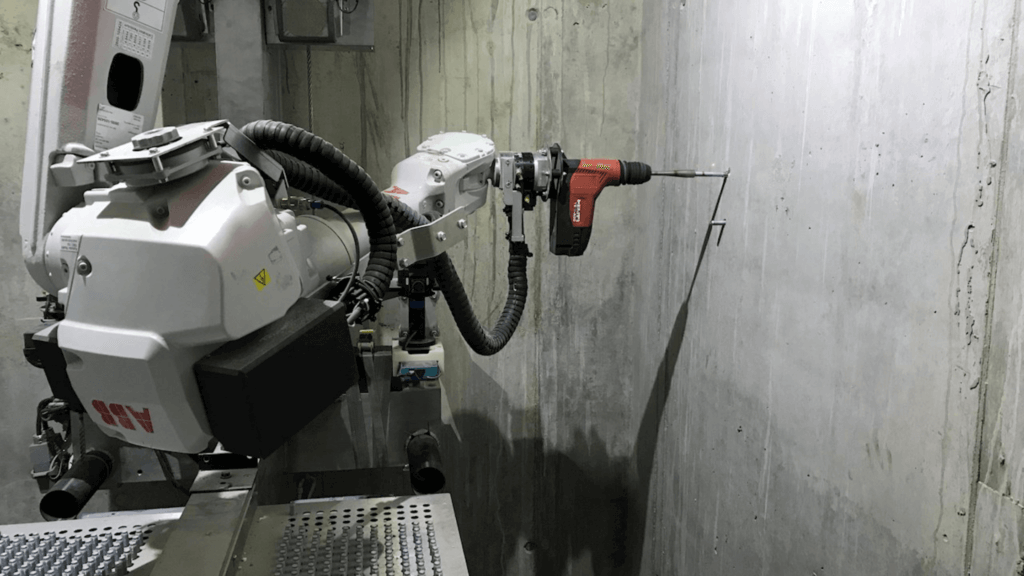

ABB Autonomous Drilling Robot

The ABB Autonomous Drilling Robot is transforming construction by automating the precise drilling of anchor bolt holes in elevator shafts, a task traditionally labor-intensive and prone to human error. Developed in collaboration with Schindler and ETH Zurich, this robot enhances efficiency and safety in elevator installations.

Key features

- AI-driven path planning for precise drilling: With advanced sensors and algorithms, the robot scans concrete surfaces to detect hidden rebar and uneven areas, adjusting drilling coordinates in real-time to maintain millimeter-level accuracy.

- Reduction of human error and labor costs: By automating repetitive and physically demanding tasks, the robot minimizes the potential for mistakes and decreases the need for manual labor, leading to cost savings and improved installation quality.

- Enhanced safety by minimizing worker exposure to high-risk tasks: Operating autonomously within elevator shafts, the robot eliminates the need for workers to perform hazardous drilling operations in confined and challenging environments, thereby reducing the risk of injuries.

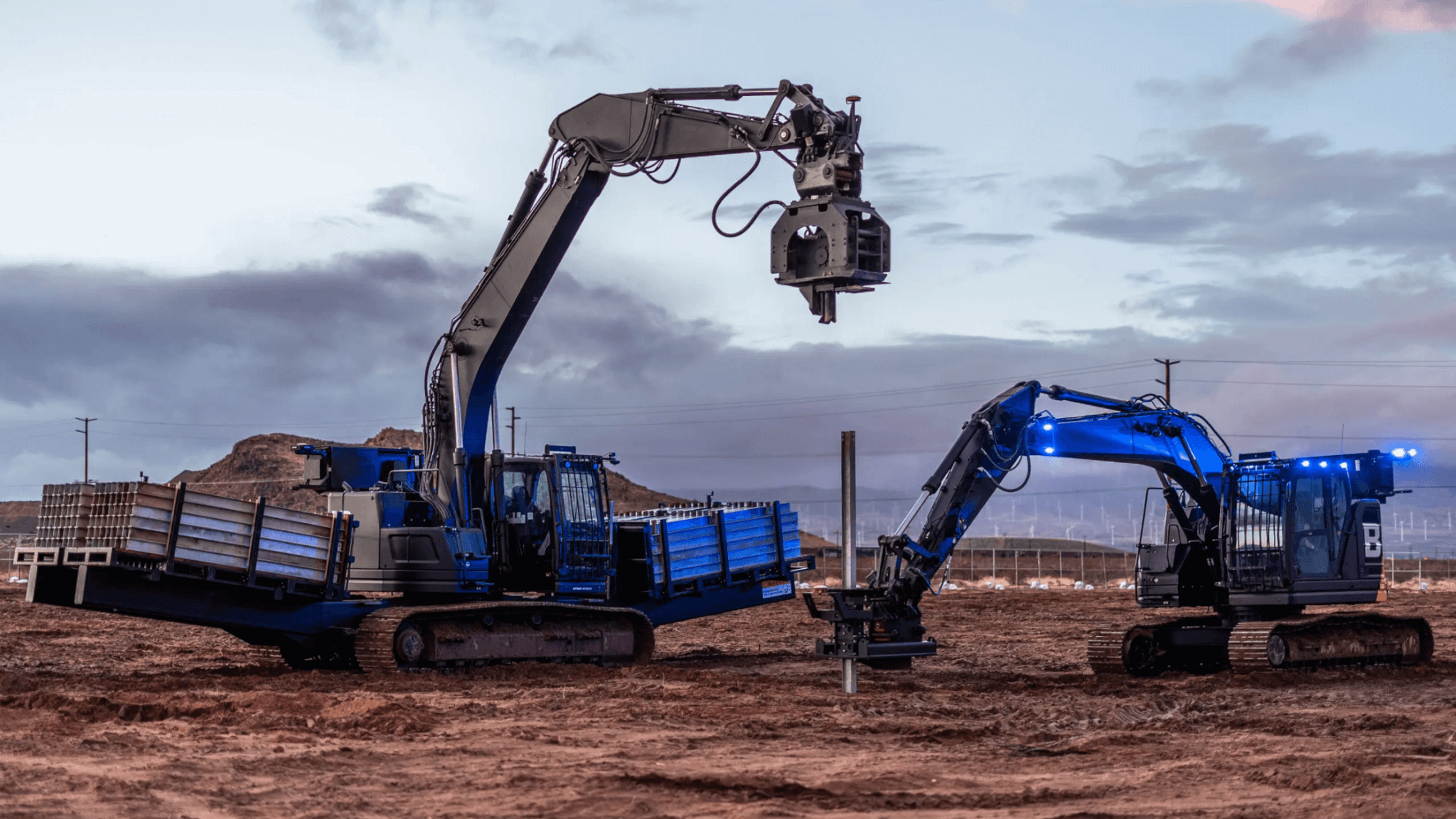

Built Robotics’ Autonomous Excavator

Built Robotics’ Autonomous Excavator transforms construction by automating critical tasks such as trenching and site preparation. Central to this innovation is the Exosystem™, an aftermarket kit that converts standard excavators into fully autonomous machines.

Key features

- Operates without human intervention: The Exosystem™ integrates advanced sensors, including 360° cameras and GPS, and a powerful onboard computer, enabling the excavator to perform tasks autonomously without direct human control.

- Reduces excavation time: The autonomous excavator can achieve production rates of up to 180 feet per hour with digging accuracy within 0.1 feet. It significantly accelerates trenching and other earthmoving activities, enhancing project timelines.

- Improves site efficiency and safety: The system minimizes the risk of human error and injuries by automating repetitive and hazardous tasks. Its 8-layer safety system, featuring robust redundancies, ensures safe operation in dynamic construction environments.

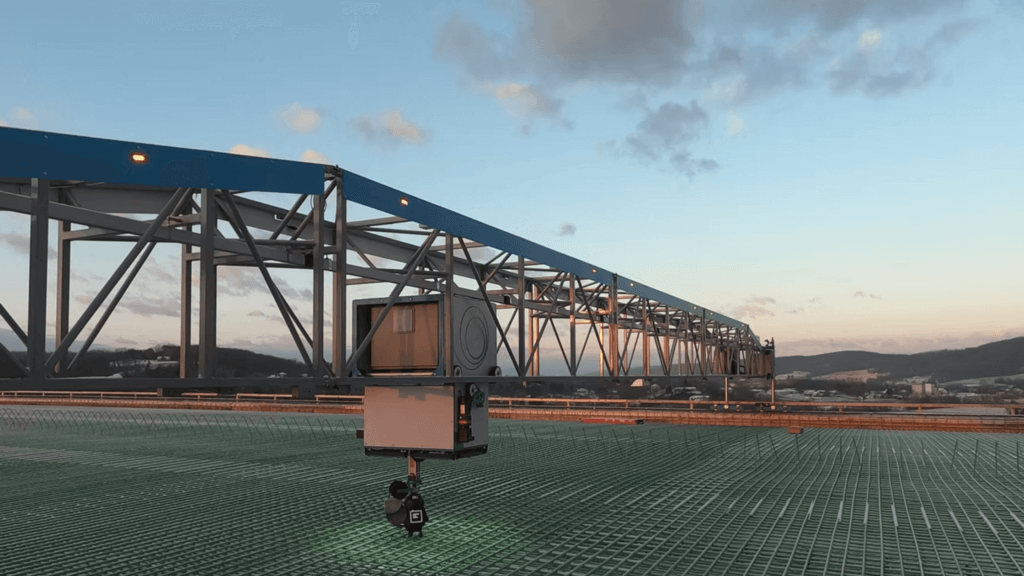

Hilti Jaibot

The Hilti Jaibot is a semi-autonomous robotic drilling system designed to enhance efficiency and precision in overhead installations, particularly for mechanical, electrical, and plumbing (MEP) applications. By automating the execution of drilling tasks based on digital plans, the Jaibot reduces manual labor and minimizes errors, streamlining the installation process.

Key features

- Designed for ceiling and overhead work, the Jaibot is engineered to drill tasks on various ceiling types, including corrugated metal deck ceilings and vertical concrete walls. It can identify and map installed profiles, align with digital plans, and adapt planned drill holes to predefined installation zones. Its drilling capabilities cover heights ranging from 0.9 to 4.8 meters, making it versatile for different project requirements.

- Reduces strain on workers: By taking over the physically demanding task of overhead drilling, the Jaibot alleviates worker fatigue and reduces the risk of injuries associated with repetitive overhead work. This allows skilled laborers to focus on supervising the robot and handling more complex tasks, thereby improving overall job satisfaction and productivity.

- Enhances precision and productivity: The Jaibot ensures accurate drilling by following precise coordinates and depths specified in digital plans, utilizing data from building information modeling (BIM). This integration minimizes errors, leads to cleaner installations, and accelerates project timelines. Additionally, the robot features an upgraded vacuum system that delivers up to 30% higher dust removal performance, contributing to a cleaner and safer work environment.

TyBOT by Advanced Construction Robotics

The TyBOT by Advanced Construction Robotics is revolutionizing bridge and road construction by automating the labor-intensive process of rebar tying. This autonomous robot efficiently identifies and secures rebar intersections, enhancing productivity and safety on construction sites.

Key features

- AI-powered automation for faster rebar tying: TyBOT utilizes advanced vision systems to autonomously detect and tie rebar intersections, achieving rates of over 1,100 ties per hour. This rapid performance significantly accelerates project timelines.

- Reduction of labor-intensive manual work: By automating the repetitive task of rebar tying, TyBOT alleviates the physical strain on workers, addressing labor shortages and allowing skilled personnel to focus on more complex aspects of construction.

- Enhanced speed and consistency: Operating autonomously without needing pre-mapping or calibration, TyBOT ensures consistent and precise ties across large-scale projects, improving overall build quality and reducing the potential for human error.

Watch this video for a visual demonstration of TyBOT in action: TyBOT – Autonomous Rebar Tying Robot | World of Concrete 2020

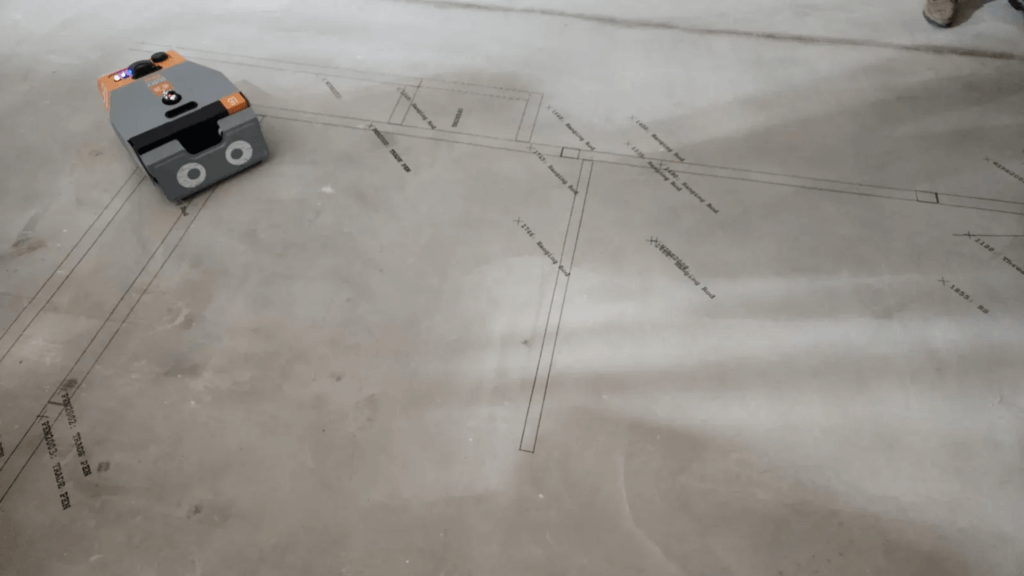

Dusty Robotics Layout Robot

Known as the FieldPrinter, this robot is revolutionizing the construction industry by automating the floor plan layout process. This innovative robot translates digital building models directly onto physical surfaces, ensuring precise alignment for walls and structural elements.

Key Features

- AI-driven accuracy in layout marking: The FieldPrinter utilizes advanced robotics and AI to interpret Building Information Modeling (BIM) data, printing full-scale layouts onto construction surfaces with an accuracy of up to 1/16 inch.

- Reduces layout time from days to hours: By automating the layout process, the FieldPrinter significantly accelerates project timelines. Traditional manual layout methods can take days or weeks, whereas the FieldPrinter can complete the same tasks up to ten times faster.

- Eliminates human error in measurements: Manual layout is susceptible to errors that can lead to costly rework. The FieldPrinter minimizes these mistakes by accurately transferring digital plans to the job site, ensuring that all structural elements are correctly positioned from the outset.

Watch here for a visual demonstration of the Dusty Robotics FieldPrinter in action: FieldPrinter – Dusty Robotics BIM-driven Layout Solution

Boston Dynamics’ Spot Robot

Boston Dynamics’ Spot Robot improves construction sites by automating inspections, data collection, and monitoring hazardous areas. This agile, quadruped robot navigates complex environments, capturing consistent data to enhance project efficiency and safety.

Key features

- Navigates rough terrain autonomously: Spot’s advanced mobility allows it to traverse dynamic construction landscapes, including stairs and uneven surfaces, ensuring comprehensive site coverage without human intervention.

- Collects real-time site data for analysis: With customizable payloads, Spot autonomously captures high-resolution images, 360° videos, and laser scans, providing accurate, real-time data to monitor progress and inform decision-making.

- Enhances worker safety in dangerous areas: By performing routine inspections in hazardous or hard-to-reach locations, Spot reduces the need for personnel exposure to potential risks, thereby improving overall site safety.

Watch here for a visual demonstration of Spot in action on construction sites: Spot Robot Testing at Construction Sites

Bottom line

AI-powered robots are no longer just a futuristic concept—they’re actively reshaping the construction industry today. These machines are helping firms meet growing demands while tackling labor shortages and optimizing workflows. From autonomous excavators to layout-marking robots, automation streamlines operations and sets new standards for precision on job sites.

As AI and robotics evolve, the industry will see even more significant advancements, making construction smarter, faster, and more sustainable. Companies that embrace these innovations will be better positioned to stay competitive, complete projects more efficiently, and adapt to the demands of an ever-changing market.

Stay ahead of the latest trends in construction technology. Subscribe to our newsletter and follow us on social media for insights on AI, robotics, and the industry’s future!