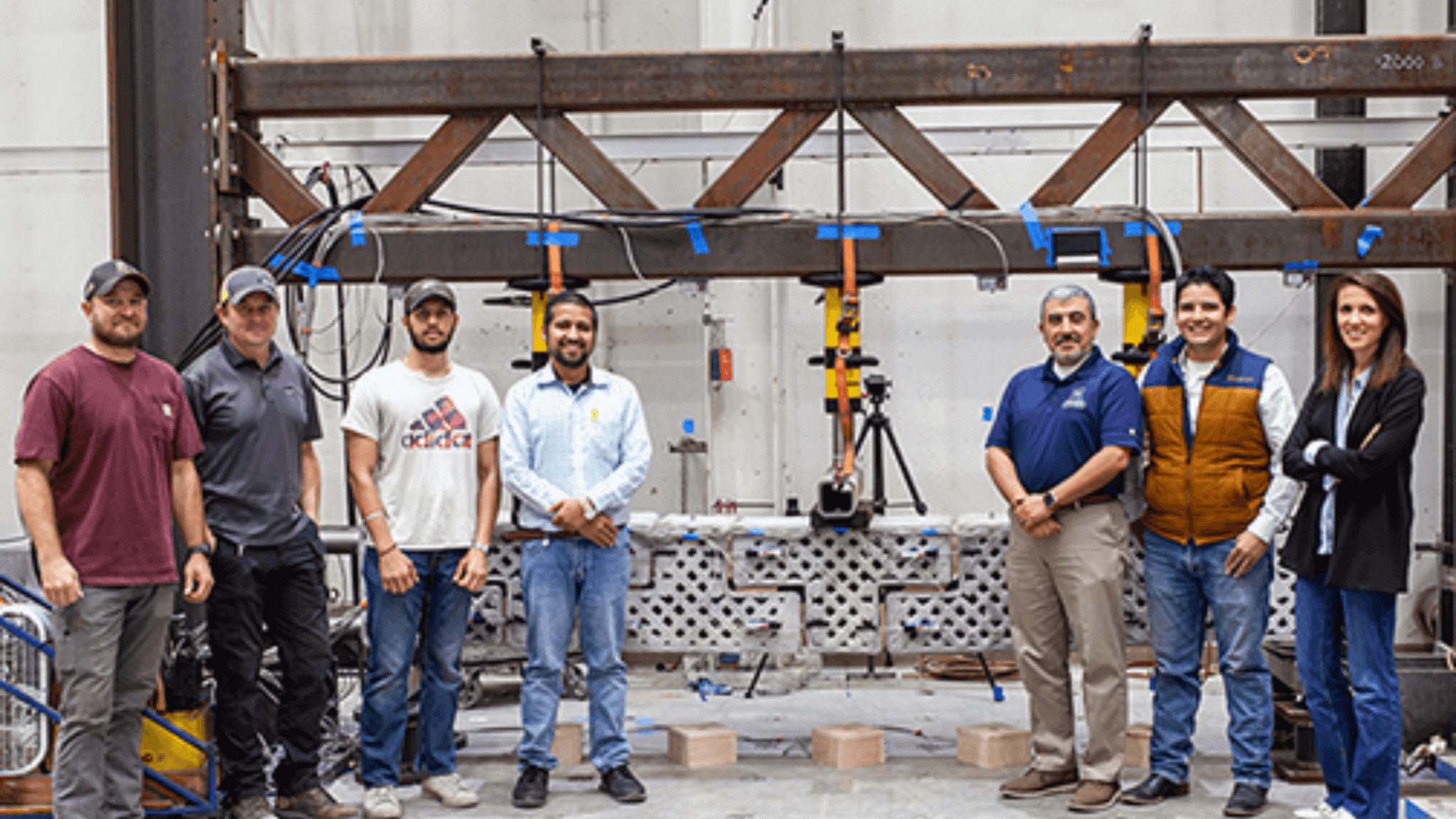

A University of Nevada research team is collaborating with the United States Army on its latest project from the Civil and Environmental Engineering department. Led by Assistant Professor Floriana Petrone and Associate Research Professor Sherif Elfass, the project aims to produce 3D-printed LEGO-like concrete modules for the U.S. Army Engineer Research and Development Center (ERDC) Construction Engineering Research Laboratory (CERL).

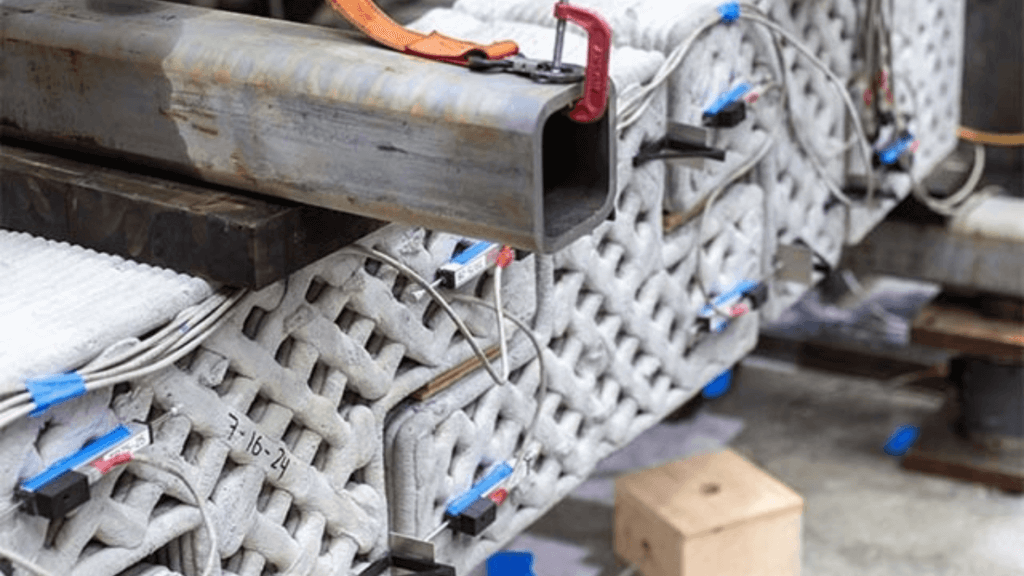

The innovation stems from the U.S. Army’s need to construct on-site infrastructure in conflict zones where military operations are underway. This new approach combines advanced numerical simulation, 3D construction, and segmental construction—building large structures using smaller segment assemblies. Together, these create a simple but structurally sound bridge or building somewhat on the fly.

Technical innovation that goes beyond construction

3D printing is becoming more often associated with new housing construction, but Petrone’s experimental program, which began earlier in 2024, tests “bridging infrastructure.” They assemble 3-foot-long printed modules from concrete that are tested and numerically simulated. This computational innovation to simulate real systems through mathematical models is an effective way to validate the experiments.

“The integration of numerical modeling with 3D printing and segmental construction provides a powerful tool for predicting structural performance before construction even begins,” Elfass says. “This allows engineers to optimize the placement of segments and the design of printed components, ensuring that printed structures meet the necessary strength and durability requirements in a variety of conditions.”

With their latest advancement in the product, the concrete components connect with cables, leaving out the need for specialized equipment. “Everything could be assembled manually on site,” Petrone said, referring to the cabling system. Specialized equipment likely won’t be available in a combat zone.

For more on the latest news, subscribe to our newsletter.