When it comes to construction site safety, headgear is often misunderstood. Many workers and managers use terms like “hard hats” and “helmets” interchangeably, which can lead to mistakes in selecting the right equipment for the job. This confusion doesn’t just affect compliance—it increases the risk of preventable injuries.

Hard hats vs. helmets: clarifying terminology

A common misconception on construction sites is that hard hats and helmets are the same. While both are designed to protect workers’ heads, they serve different purposes and offer various degrees of protection.

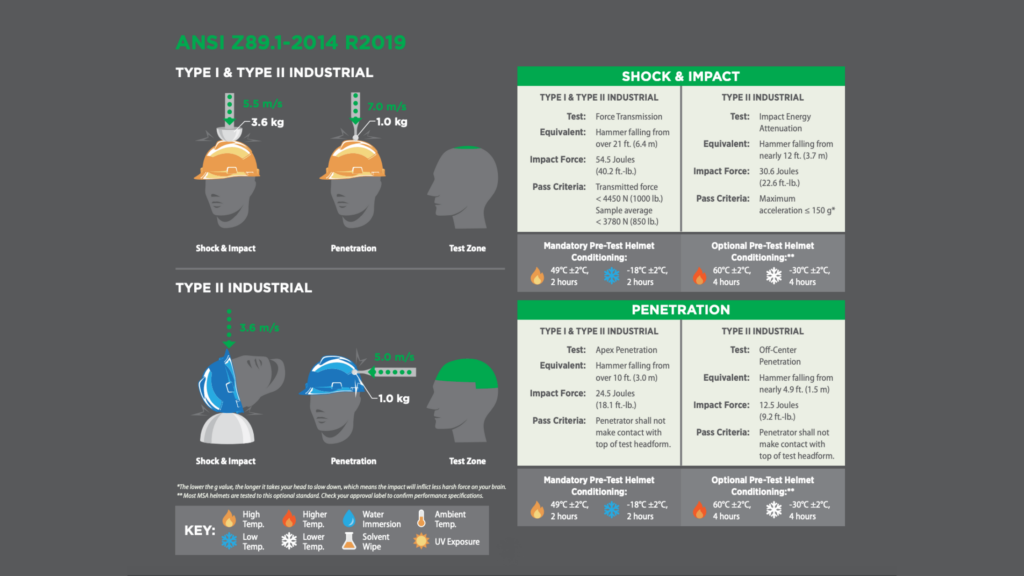

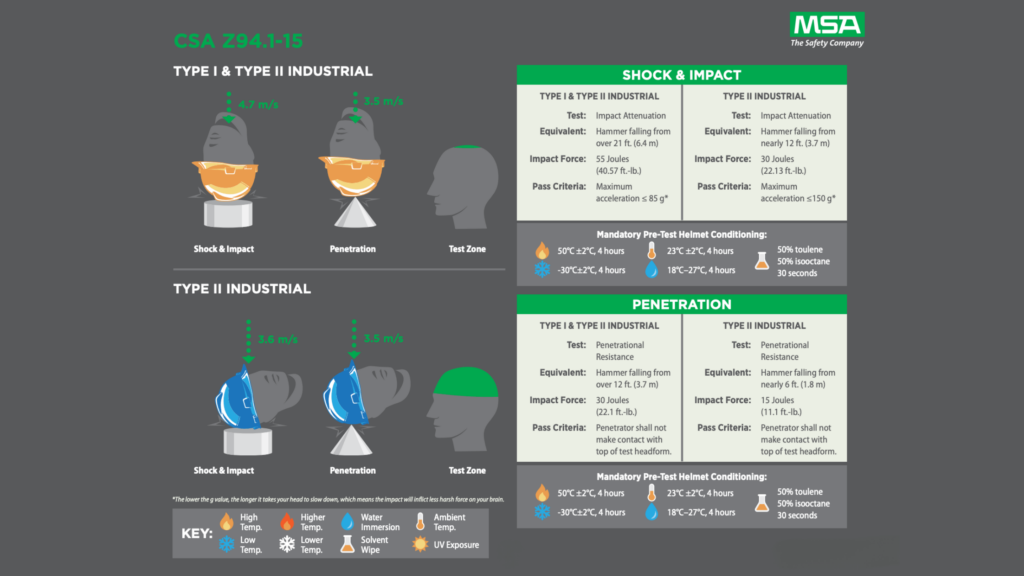

Hard hats are the traditional choice on most job sites. They’re built to shield against vertical impacts, like tools or debris falling from above, and typically rely on a suspension system to absorb the force. However, they’re not as effective for side impacts or falls and often don’t include straps to keep them secure during movement.

On the other hand, helmets are gaining traction for their added safety features. They’re designed to protect against multiple types of impacts, including lateral ones, and often come with chin straps to ensure they stay in place. These helmets are especially useful for jobs involving dynamic activities, such as working on scaffolds or operating heavy machinery.

Understanding the difference between these two types of headgear can help workers and managers make better choices, reduce risks, and improve safety outcomes.

Headgear challenges

Managing headgear use on construction sites is more complicated than it seems. Workers often face issues with fit, comfort, and usability, leading to improper use or no use. Ensuring consistent compliance while balancing worker needs and safety standards becomes a daily challenge for managers. These difficulties matter because headgear is a worker’s first line of defense against serious injuries, and lapses in its use can have life-altering consequences.

Here are some of the common challenges faced by site managers:

- Consistent use: Workers often skip wearing headgear, viewing it as unnecessary or uncomfortable, especially during short tasks. This inconsistency leaves them vulnerable to injuries.

- Proper fit and comfort: Ill-fitting hard hats and helmets are less effective and can distract workers. Discomfort often leads to improper adjustments or removal during work.

- Appropriate selection for the job: Different tasks require different levels of protection, but workers are often equipped with gear that doesn’t match the risks involved, such as using hard hats when helmets are needed for lateral impact protection.

- Heat stress: Wearing headgear in hot weather can increase discomfort and heat exhaustion, leading to non-compliance or unsafe modifications like removing the suspension for ventilation.

- Storage and maintenance: Improperly stored or damaged headgear is less effective, yet many sites lack regular inspections or replacement protocols.

- Resistance to change: Some workers are reluctant to adopt modern helmets, sticking to traditional hard hats due to familiarity, cost, or skepticism about the benefits.

The importance of education

Education and training on proper headgear use are vital for keeping workers safe on construction sites. Without knowing when, why, and how to use the right equipment, workers are likelier to make mistakes or skip head protection altogether, leaving themselves vulnerable to severe injuries.

The numbers speak for themselves. From 2003 to 2010, more than 2,200 construction workers died from traumatic brain injuries (TBIs), accounting for 25% of all construction-related fatalities. Many of these incidents involved falls or struck-by accidents where proper headgear could have made a life-saving difference. Workers who don’t fully understand the risks of not wearing or improperly using headgear are more likely to fall victim to such preventable tragedies.

Adding to the problem is the confusion around headgear terminology. A report by J.J. Keller revealed that 80% of safety professionals mistakenly believed only helmet-style protection offers multi-directional impact resistance. This misunderstanding affects compliance and can lead to poor decision-making about which equipment to provide.

Proper training ensures that workers understand the differences between hard hats and helmets and when to use each one. It also helps create a culture where safety is taken seriously, making it easier for managers to enforce rules and for workers to adopt safer habits. When workers know how to properly adjust their headgear, understand its limitations, and recognize when it needs replacement, they’re far less likely to get injured on the job.

How to improve headgear safety in construction

Improving headgear safety on construction sites means tackling common issues with practical solutions that workers and managers can apply daily. Here are the top factors to consider:

1. Better education and training

Teaching workers how to choose, wear, and maintain headgear is one of the most practical ways to reduce injuries. Training sessions should include real-life examples of accidents that could have been prevented with proper gear. When workers understand the risks and know how to protect themselves, they’re more likely to take safety seriously.

2. Terminology standardization

Misunderstandings about what makes a “hard hat” different from a “helmet” can lead to poor equipment choices. Standardizing these terms across the industry ensures everyone knows what kind of protection is required for different jobs. Clear definitions and examples should be included in safety manuals and job-site signage.

3. Regular audits and inspections

Checking headgear regularly can catch problems before they lead to injuries. Managers should ensure workers are wearing their gear correctly and replace items that are damaged or past their expiration date. These inspections don’t just prevent accidents—they also show workers that safety is a shared priority.

4. Clear communication on safety standards

Workers are more likely to follow the rules when they understand them. Managers should explain headgear policies in simple terms and use visuals to reinforce those messages. When everyone knows the “why” behind a rule, it feels less like a burden and more like a necessary step to stay safe.

5. Improved headgear design

Workers are more likely to keep their headgear on if it’s comfortable and practical. Lightweight helmets with ventilation and adjustable straps make long shifts in the heat easier to manage. Partnering with safety equipment suppliers to find better options can go a long way in improving compliance.

6. Building a culture of safety

Creating a safer workplace isn’t just about rules—it’s about teamwork. Encouraging workers to speak up when they notice issues or suggest improvements builds trust and makes safety a shared effort. When workers feel involved, they’re more likely to follow the rules and support others in doing the same.

Bottom line

Confusion around headgear is a risk that puts lives on the line. By addressing this issue through better education, standardized terminology, and improved practices, construction sites can create a safer environment where workers are equipped to protect themselves.

Want to stay ahead of the latest safety updates and strategies? Subscribe to our newsletter and follow us on social media to avoid missing out on insights that could make your job site safer and more efficient tomorrow.